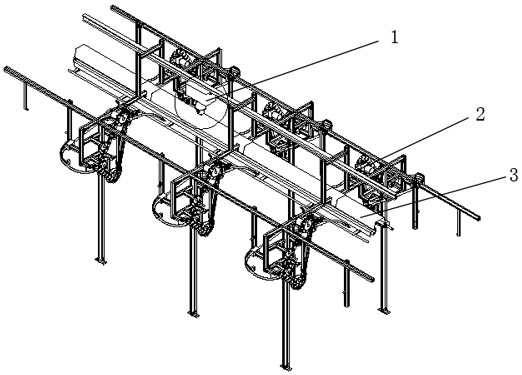

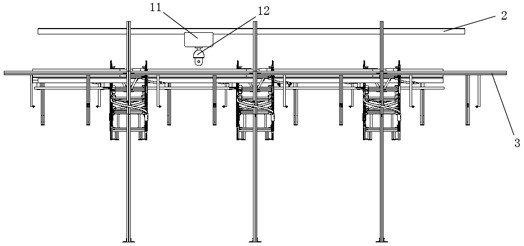

System and method for integrated monitoring and patrolling of hanging system

A system integration and hanging technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as inability to directly analyze the cause of alarms, save manpower, feedback problems quickly and accurately, and avoid monitoring dead ends.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

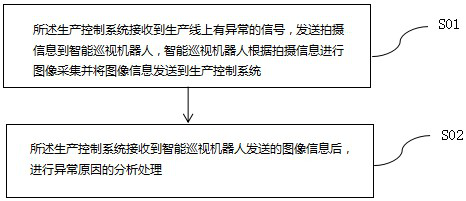

[0054] A hanging system integrated monitoring and inspection method is realized based on the above-mentioned hanging system integrated monitoring and inspection system and a production control system. Methods include:

[0055] S01, when the production control system receives a signal that a production line is abnormal at a certain station or a certain process, it sends shooting demand information to the intelligent patrol robot 1, and the shooting demand information includes the shooting location and shooting content. Each station has a corresponding ID, and each process also has a corresponding number. The shooting position in the shooting information is the corresponding ID station or the corresponding numbered process corresponding to the transportation track 2 position. The shooting content in the shooting information includes the conditions of the production site at various angles of the corresponding station or the corresponding process.

[0056] The intelligent patrol ...

Embodiment 2

[0063] A hanging system integrated monitoring and inspection method is realized based on the above-mentioned hanging system integrated monitoring and inspection system and a production control system. Methods include:

[0064] S01, when the production control system receives an alarm signal of abnormality, damage, or shutdown of a certain equipment on the production line, it sends shooting demand information to the intelligent patrol robot 1, and the shooting demand information includes the shooting location and shooting equipment number. The shooting location included in the shooting requirement information includes the location of the transport track 2 for the equipment.

[0065] The intelligent inspection robot 1 moves to the corresponding shooting position, collects images of the corresponding numbered equipment and sends the image information to the production control system.

[0066] Preferably, when the transportation track 2 reaches the position specified by the shoot...

Embodiment 3

[0071] S01, when the production control system does not receive an abnormal signal on the production line, the intelligent patrol robot 1 moves on the transport track 2 at a preset speed, and at the same time collects images from all directions on the hanging production loop line 3 and Send the image information to the production control system.

[0072] Such a normal inspection scheme enables the intelligent inspection robot 1 to move while shooting, and collect images from various directions on the hanging production loop 3, so as to understand more comprehensively the production conditions and equipment operation conditions on the hanging production loop 3, and to maximize Supervision.

[0073] S02. After the production control system receives the image information sent by the intelligent patrol robot 1, it performs comparison and analysis. The specific step is to compare the image information with the corresponding table in the production control system to detect whether t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com