Chemical vapor deposition product component prediction method

A technology of deposition products and chemical vapor phase, applied in chemical property prediction, neural learning methods, chemical statistics, etc., can solve difficult problems such as single-objective or multi-objective optimization problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

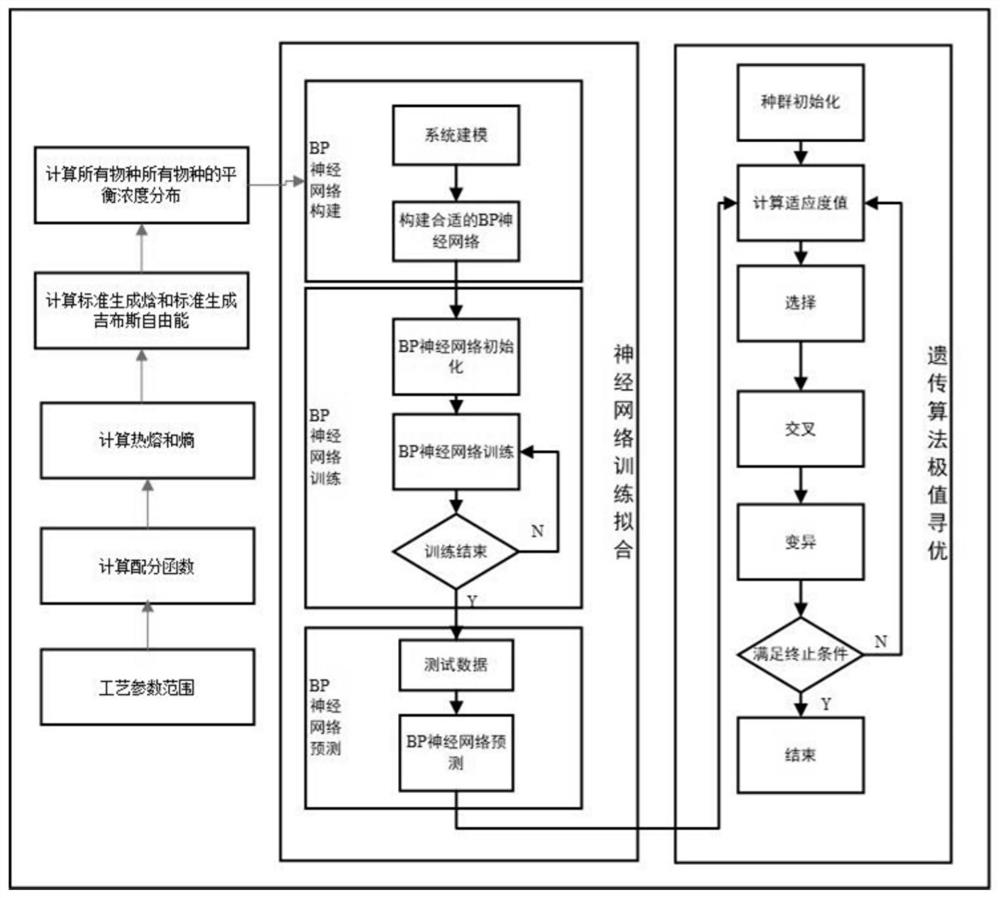

[0090] Such as figure 1 Shown, a kind of chemical vapor phase multi-component deposition product component prediction method, comprises the following steps:

[0091] Step S1, according to the process conditions, calculate the partition function:

[0092] Translational partition function: when the molecular translational kinetic energy difference is small, the translational partition function q t The expression is

[0093]

[0094] In the formula, m is the mass of the molecule, V is the volume of the molecule, T is the temperature, k is Boltzmann's constant, and h is Planck's constant.

[0095] According to Avogadro's formula pV=nRT=N A kT (where p is the gas pressure, R is the gas constant, N A is Avogadro's constant), we know that V=N A kT / p, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com