Large-section chamber soft rock bottom plate foundation treatment method

A floor foundation and treatment method technology, which is applied in underground chambers, earthwork drilling, wellbore lining, etc., can solve problems such as bottom heaving and cracking of the foundation, damage to the foundation of the winch installation, and increased maintenance costs. , to achieve the effect of reducing deformation, increasing bearing capacity and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

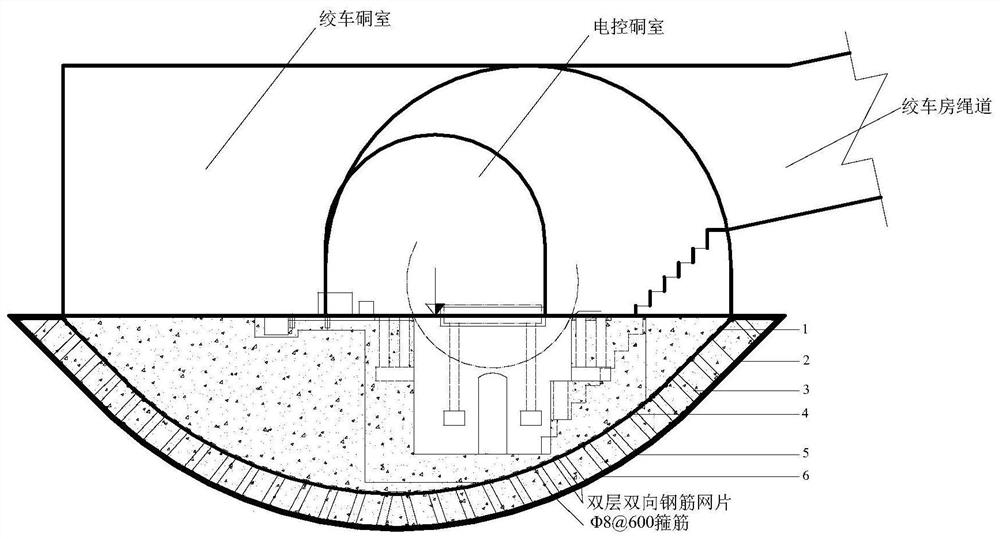

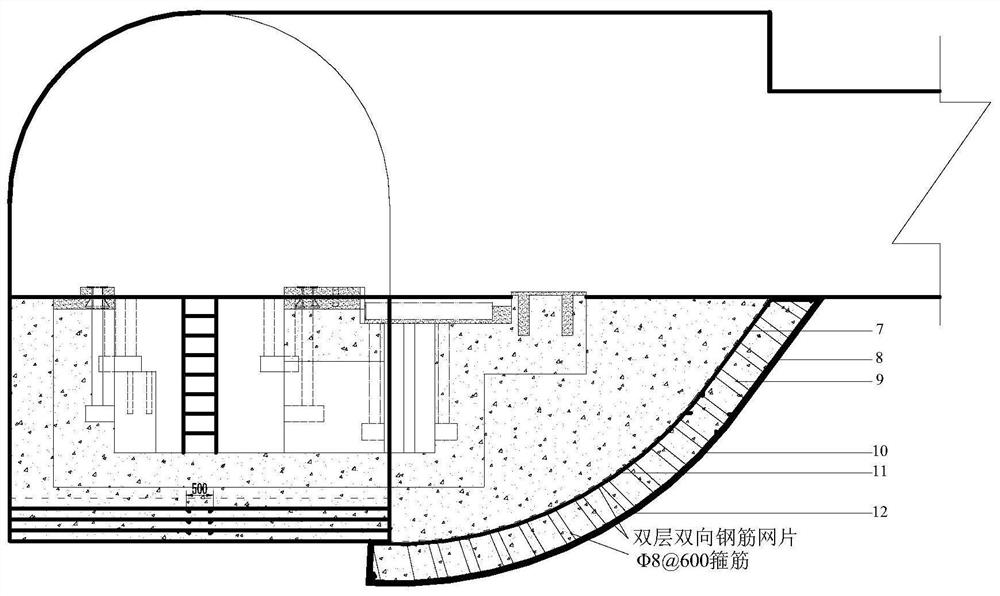

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

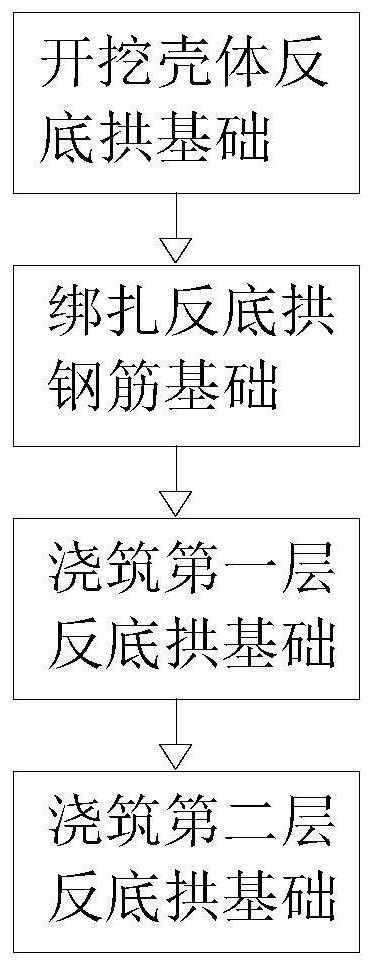

[0020] The method for treating the soft rock floor foundation of a large-section chamber includes the following steps:

[0021] S1: Excavate the anti-bottom arch foundation of the shell, and excavate the anti-bottom arch foundation of the winch chamber and the electric control chamber according to the design requirements;

[0022] S2: On the basis of excavation and formation, the steel bars are bound to the anti-bottom arch steel bar foundation according to the design requirements. The overlapping length of the steel bars is 500mm. The steel bars include the first steel bar 1, the second steel bar 2, the third steel bar 3, and the fourth steel bar 4 , No. 5 rebar 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com