Self-cooked fermented half-dry rice noodles and preparation method thereof

A dry rice flour and self-cooking technology, applied in the field of semi-dry rice flour and its preparation, can solve the problems of prolongation of semi-dry rice flour, undisclosed cadmium removal efficiency, etc., and achieve the effects of good taste, low cost, and prolonged shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

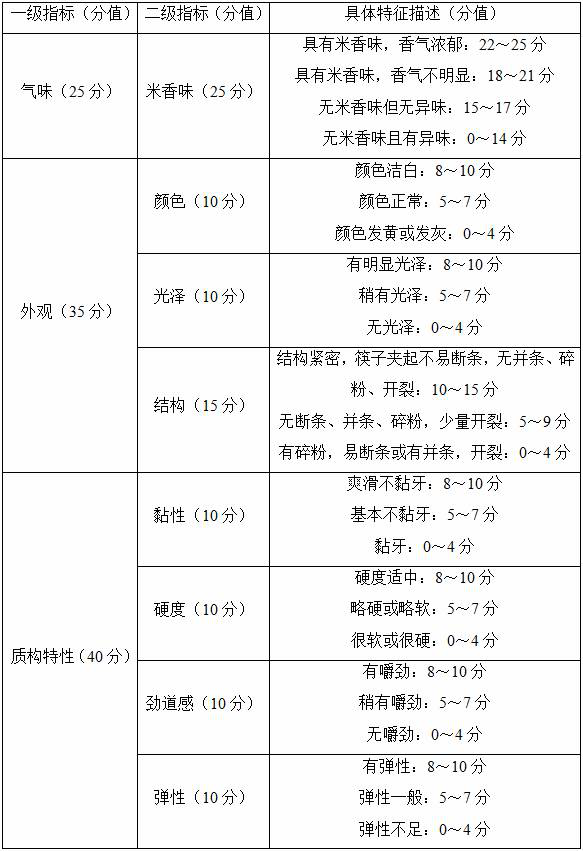

Image

Examples

Embodiment 1~3

[0045] The raw materials and parts by weight of Examples 1-3 of a self-cooked fermented semi-dry rice flour are shown in Table 1.

[0046]Table 1 A self-cooked fermented semi-dry rice flour Example 1-3 raw materials and parts by weight

[0047]

[0048] Note: "-" in the table means not added.

Embodiment 1

[0050] (1) According to the raw materials and parts by weight in Example 1 in Table 1, rice 1 was placed in 90 parts by weight of water, and fermented once at 30°C for 72 hours, then filtered, washed with water until the pH value was 4.6, and drained. cadmium-depleted rice;

[0051] (2) According to the raw materials and parts by weight in Example 1 in Table 1, add 23 parts by weight of water to the decadmium-removed rice obtained in step (1), conduct semi-dry milling, and sieve until the particle size is 80 meshes. Add starch additives and fresh-keeping and antibacterial additives, add water to adjust the powder to a moisture content of 25%, and obtain semi-dry powder;

[0052] (3) Steam the semi-dry powder obtained in step (2) at 80°C and a pressure of 0.2MPa for 5 minutes, then extrude at a screw speed of 35r / min, and at 10°C and a wind speed of 3m / s , after air-drying on the rod for 3 hours, aging treatment at 52°C for 8 hours, and then at 85°C and a pressure of 0.3MPa, c...

Embodiment 2

[0055] (1) According to the raw materials and parts by weight in Example 2 in Table 1, put the rice 2 in 120 parts by weight of water at 40°C for 48 hours of primary fermentation, then add the cadmium-removing bacteria preparation, at 35°C, Carry out secondary fermentation for 24 hours, filter, wash with water until the pH value is 4.2, and drain to obtain cadmium-depleted rice;

[0056] (2) According to the raw materials and parts by weight in Example 2 in Table 1, add 30 parts by weight of water to the decadmium rice obtained in step (1), conduct semi-dry milling, and sieve until the particle size is 70 mesh. Add starch additives and fresh-keeping and antibacterial additives, add water to adjust the powder to a moisture content of 30%, and obtain semi-dry powder;

[0057] (3) Steam the semi-dry powder obtained in step (2) at 85°C and a pressure of 0.15MPa for 4 minutes, and extrude at a screw speed of 40r / min, at 20°C and a wind speed of 2m / s After air-drying on the hanging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com