Low-GI artificial rice and preparation method thereof

An engineering and rice technology, applied in the field of low GI engineering rice and its preparation, can solve the problems of high GI value of rice, poor taste of engineering rice, easy deformation and breaking, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

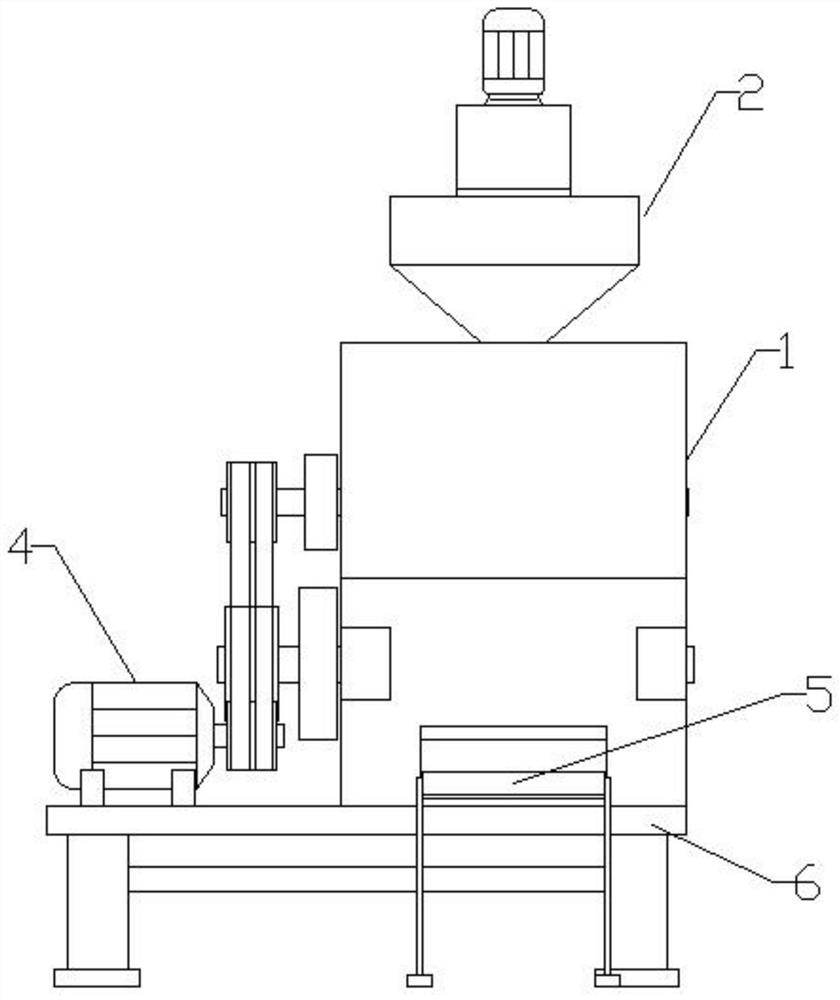

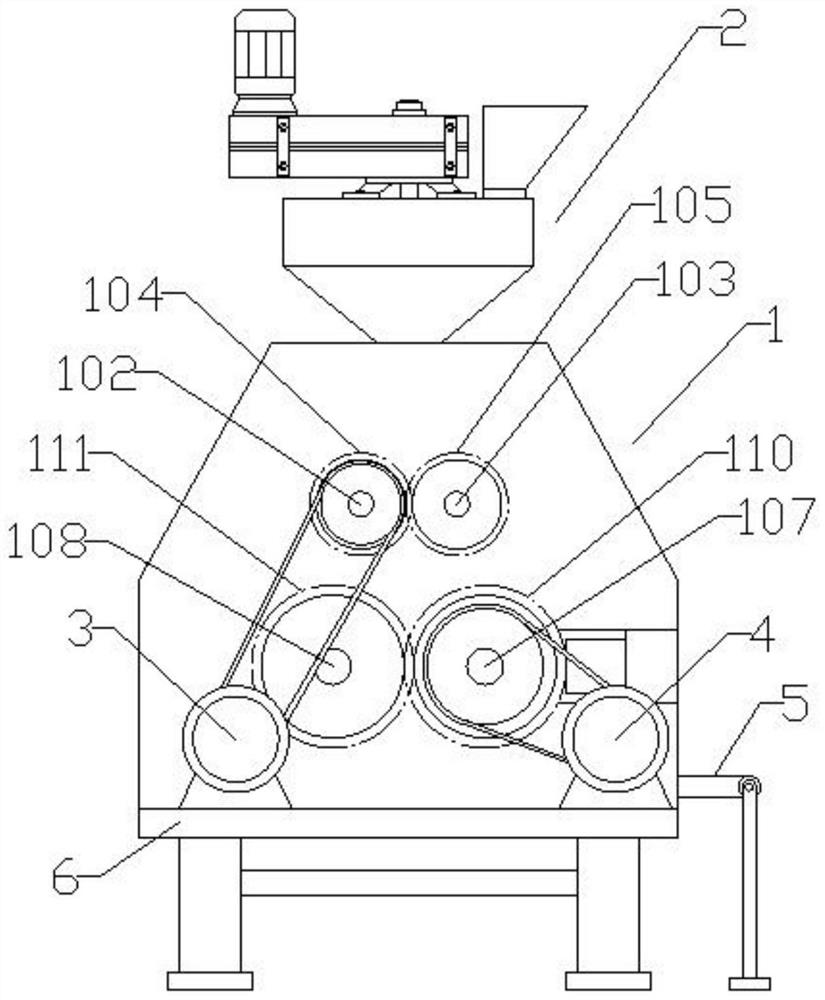

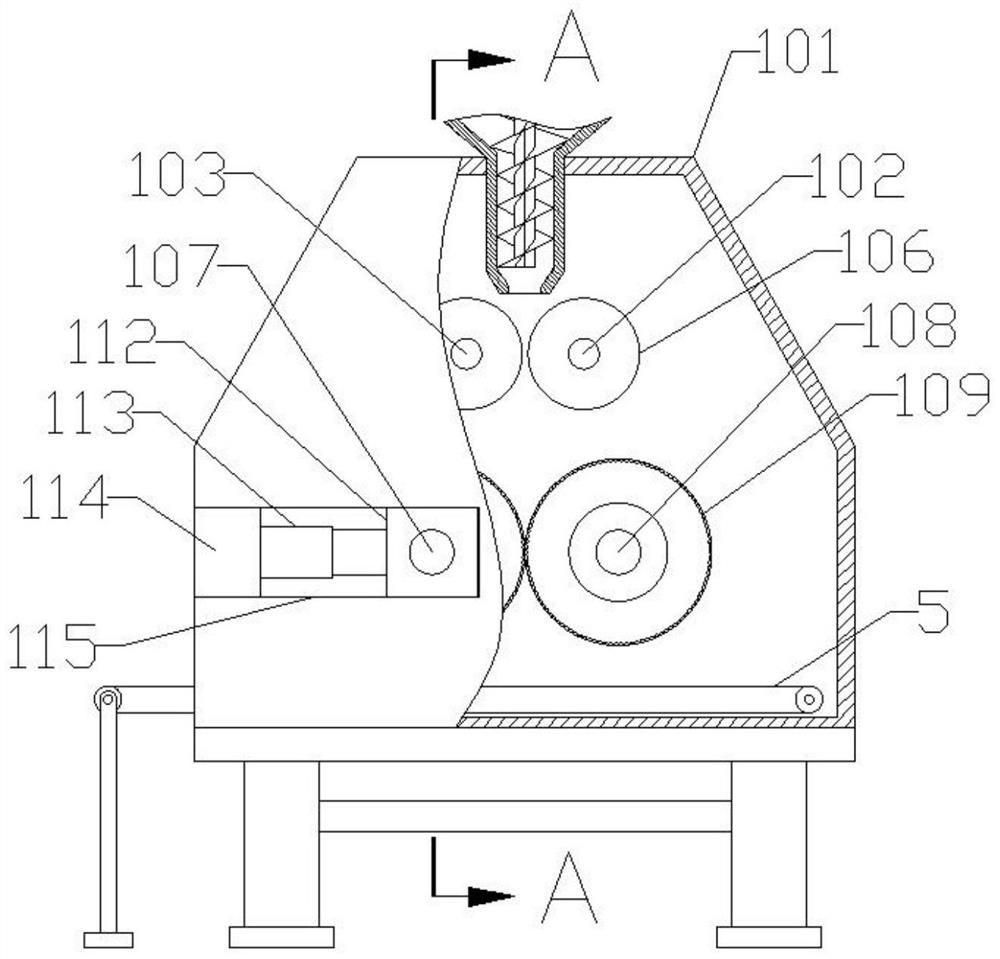

Image

Examples

Embodiment 1

[0043] A low GI engineering rice, made of the following raw materials in parts by weight: 20 parts of millet, 10 parts of buckwheat, 10 parts of oats, 20 parts of coix seed, 10 parts of black beans, 30 parts of corn, 10 parts of glutinous rice flour, 10 parts of flour, 20 parts 1 part of broken rice flour, 15 parts of yam powder, 0.03 part of vitamin B1, 0.2 part of bone meal, 0.01 part of lysine, 1 part of table salt, 10 parts of polishing liquid and 0.2 part of cement;

[0044] The preparation method of this kind of low GI engineering rice comprises the steps:

[0045] Step 1. Mix millet, buckwheat, oats, coix seed, black beans and corn and add them to the extruder. Extrude at a temperature of 115°C and a rotation speed of 160r / min, then pulverize through a superfine pulverizer and pass through 100 mesh Sieve to obtain miscellaneous grain powder;

[0046] Step 2: Add miscellaneous grain powder, glutinous rice flour, flour, broken rice flour and yam powder into the blender, ...

Embodiment 2

[0054] A low GI engineering rice, made of the following raw materials in parts by weight: 20 parts of millet, 10 parts of buckwheat, 10 parts of oats, 20 parts of coix seed, 10 parts of black beans, 30 parts of corn, 13 parts of glutinous rice flour, 10 parts of flour, 20 parts of 1 part broken rice flour, 18 parts yam powder, 0.03 part vitamin B1, 0.2 part bone meal, 0.01 part lysine, 1 part table salt, 12 parts polishing liquid and 0.2 part cementing agent;

[0055] The preparation method of this kind of low GI engineering rice comprises the steps:

[0056] Step 1. Mix millet, buckwheat, oats, coix seed, black beans and corn and add them to the extruder. Extrude at a temperature of 115°C and a rotation speed of 160r / min, then pulverize through a superfine pulverizer and pass through 100 mesh Sieve to obtain miscellaneous grain powder;

[0057] Step 2, add miscellaneous grain powder, glutinous rice flour, flour, broken rice flour and yam powder into the blender, add water wi...

Embodiment 3

[0065] A low GI engineering rice, made from the following raw materials in parts by weight: 20 parts of millet, 10 parts of buckwheat, 10 parts of oats, 20 parts of coix seed, 10 parts of black beans, 30 parts of corn, 15 parts of glutinous rice flour, 10 parts of flour, 20 parts of 1 part of broken rice flour, 20 parts of yam powder, 0.03 part of vitamin B1, 0.2 part of bone meal, 0.01 part of lysine, 1 part of table salt, 16 parts of polishing liquid and 0.2 part of cement;

[0066] The preparation method of this kind of low GI engineering rice comprises the steps:

[0067] Step 1. Mix millet, buckwheat, oats, coix seed, black beans and corn and add them to the extruder. Extrude at a temperature of 115°C and a rotation speed of 160r / min, then pulverize through a superfine pulverizer and pass through 100 mesh Sieve to obtain miscellaneous grain powder;

[0068] Step 2: Add miscellaneous grain powder, glutinous rice flour, flour, broken rice flour and yam powder into the blen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com