Sectional type guide plate, flue gas on-line adjusting and flow equalizing device and flow equalizing method

A deflector and segmented technology, which is applied in the field of SCR denitrification in coal-fired power plants, can solve problems such as difficult adjustment and unsatisfactory flow field adjustment, and achieve the effect of timely and accurate flow field adjustment and change of roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

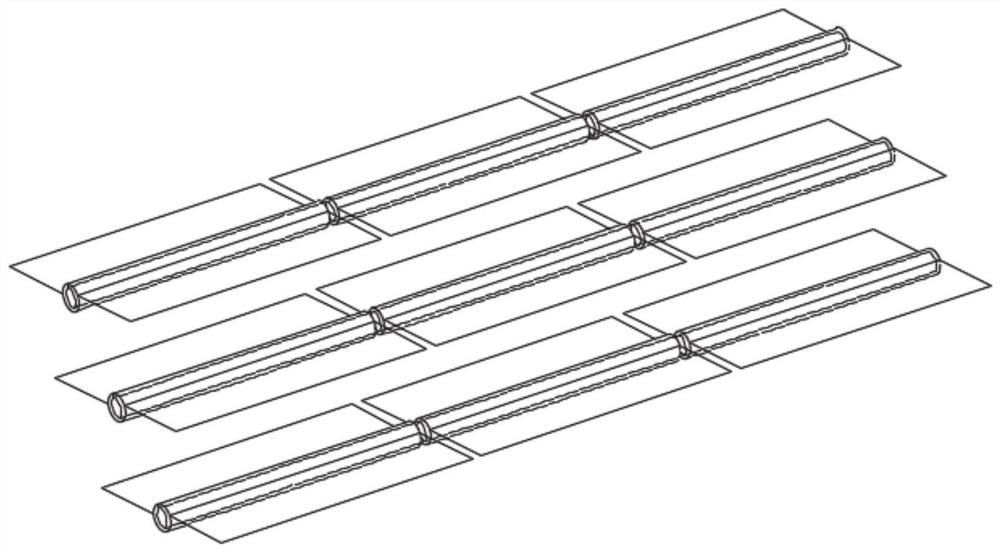

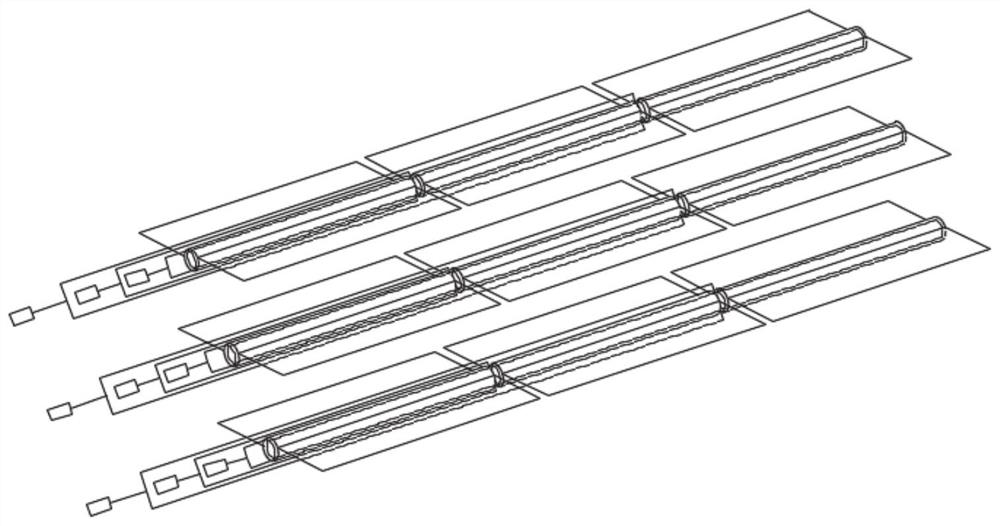

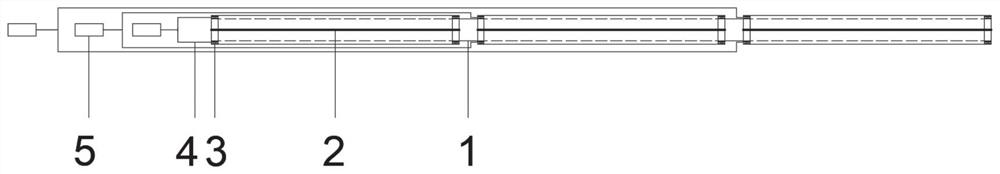

[0049] figure 1 It is a schematic structural diagram of a typical embodiment of the segmented deflector of the present invention. figure 2 It is a perspective structural diagram of a segmented deflector according to an embodiment of the present invention. On the basis of the segmented deflector, a power part is added, wherein the power part is composed of a motor and a rotating shaft. The overall design consists of a main shaft 1, a deflector 2, a bearing 3, a rotating shaft 4 and a motor 5 with an angle sensor. The control device of each deflector adopts a multi-axis design. Each flow deflector is controlled by an independent motor, and the motor and the flow deflector are connected by a rotating shaft. The motor can act after receiving the signal from the calculation and control device, thereby driving the flow deflector to rotate.

[0050] Such as Figure 4 As shown, in order to adjust the uniformity of the flue gas flow field at the outlet of the dust collector, accordi...

Embodiment 2

[0053] The layout of the first-stage deflector unit 11 is determined by the numerical simulation results, such as Figure 5 From the shown ammonia injection grille to the height of 1 / 3 of the top section, three sections of deflectors are arranged in sequence along the width direction of the flue at equal intervals, and each section of the deflector is equipped with three pieces of deflectors. The rotation angle of each deflector around the axis is -15° to 15° (the initial installation angle is defined as 0°). The distance between the baffles and between the baffles and the flue is greater than L1sin15° (L1 is the length of the first-stage baffles).

[0054] When the second stage deflector unit 12 is installed, it is arranged in such as Figure 5 At the cross-section of the flue outlet shown, three sections of deflectors are arranged equidistantly along the height direction of the flue. The deflectors are installed parallel to the inclined cover of the denitrification system, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com