Matte abrasive block and preparation method thereof

A technology of smooth grinding and preparation steps, applied in grinding/polishing equipment, abrasives, grinding devices, etc., can solve the problems that the surface of the workpiece cannot meet the quality requirements of the matte surface, the surface of the workpiece is rough, and the profiling ability is poor. Achieve the effect of reducing operation and management costs, good profiling performance and wear resistance, and no dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

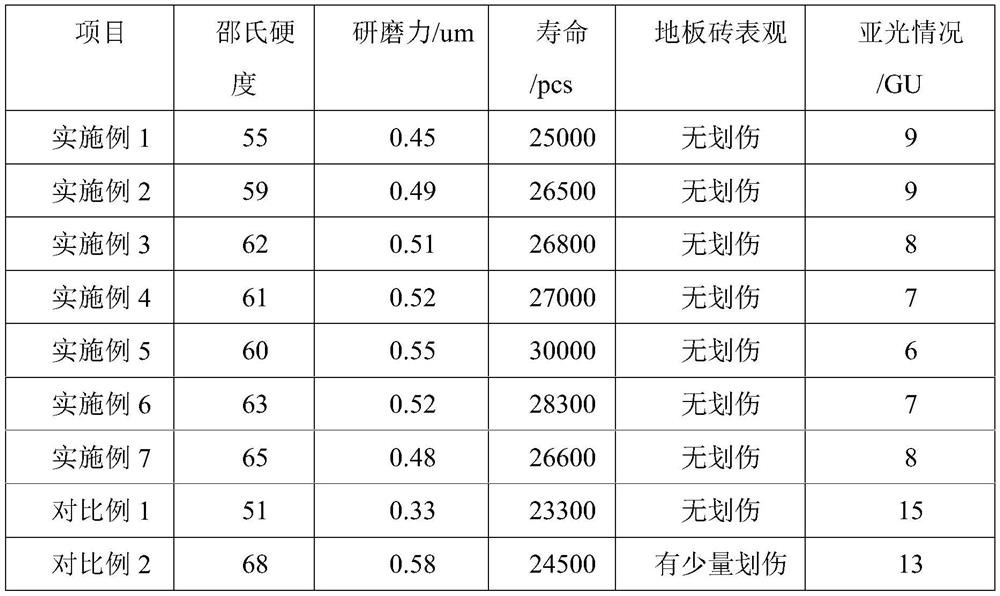

Examples

preparation example Construction

[0046] The present invention also provides a method for preparing a matte grinding block, comprising the following preparation steps:

[0047] S1: First weigh each component according to the formula, and set aside;

[0048] S2: Mix the epoxy resin and the coupling agent, and stir evenly to obtain the first mixed liquid;

[0049] S3: adding white carbon black to the first mixed solution, stirring evenly to obtain the second mixed solution;

[0050]S4: adding polyvinyl butyral and nitrile rubber to the second mixed solution in sequence, and stirring evenly to obtain a third mixed solution;

[0051] S5: Add silicon carbide and curing agent to the third mixed solution in turn, stir quickly and fully, then pour it into the mold quickly, flatten it with a press, the pressure of the press is 20MPa, and take it out from the mold after curing , put it in a drying oven at 80°C-90°C, keep warm for 4h-5h, take it out, stick it, pack it, and store it.

Embodiment 1

[0054] A matte grinding block, comprising the following components by weight:

[0055] 5 parts of epoxy resin; 1 part of curing agent; 0.2 parts of coupling agent; 0.5 parts of white carbon black; 0.3 parts of polyvinyl butyral; 6 parts of silicon carbide; 1 part of nitrile rubber.

[0056] The preparation method of the matt grinding block comprises the following preparation steps:

[0057] S1: First weigh each component according to the formula, and set aside;

[0058] S2: Mix the epoxy resin and the coupling agent, and stir evenly to obtain the first mixed liquid;

[0059] S3: adding white carbon black to the first mixed solution, stirring evenly to obtain the second mixed solution;

[0060] S4: adding polyvinyl butyral and nitrile rubber to the second mixed solution in sequence, and stirring evenly to obtain a third mixed solution;

[0061] S5: Add silicon carbide and curing agent to the third mixed solution in turn, stir quickly and fully, then pour it into the mold qui...

Embodiment 2

[0063] Different from Example 1, the matt grinding block of Example 2 includes the following components by weight:

[0064] 32 parts of epoxy resin; 20 parts of curing agent; 1.5 parts of coupling agent; 5 parts of white carbon black; 5 parts of polyvinyl butyral; 40 parts of silicon carbide; 6 parts of nitrile rubber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com