Method for separating and purifying nicotinic acid from 3-cyanopyridine wastewater

A technology of cyanopyridine and nicotinic acid, which is applied in the field of chemical intermediate waste treatment, to achieve the effects of environmental protection, simple process and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Resin activation: Soak in analytical pure methanol for 4 to 12 hours, treat with 4% (g / 100mL) NaOH solution, and wash with water;

[0033] (2) Waste water pretreatment: get 4kg waste water and add the active carbon decolorization filtration of waste water quality 3%;

[0034] (3) Adsorption on the column: the waste water in step (2) is adsorbed on the column with macroporous ion exchange resin Haipu HP334, and the flow rate is controlled at 1BV / hr;

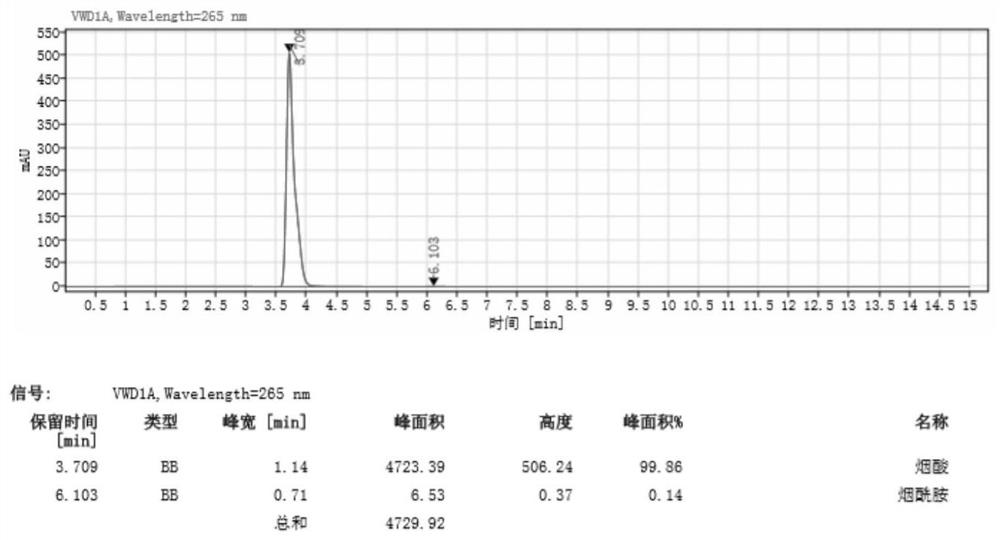

[0035] (4) Analysis: use hot water at a temperature of 70°C for analysis, with a flow rate of 2BV / hr, to obtain a niacin analysis solution, and sample T0;

[0036] (5) Resin regeneration: After the analysis is finished, feed 3 times of column volume methanol, control flow rate 0.5BV / hr; Wash with water to pH7.0±0.5, control flow rate 1BV / hr;

[0037] (6) Concentrated crystallization: Concentrate the niacin analysis solution in step (4) by 20 times, add 3% activated carbon of the concentrated solution for decolorizatio...

Embodiment 2

[0042] (1) Resin activation: Soak in methanol for 4 to 12 hours, treat with 4% (g / 100mL) NaOH solution, and wash with water;

[0043] (2) Waste water pretreatment: get 4.0kg waste water and add activated carbon decolorization filtration of waste water quality 4%;

[0044] (3) Adsorption on the column: the waste water in step (2) is adsorbed on the column with macroporous ion exchange resin Haipu HP334, and the flow rate is controlled at 1BV / hr;

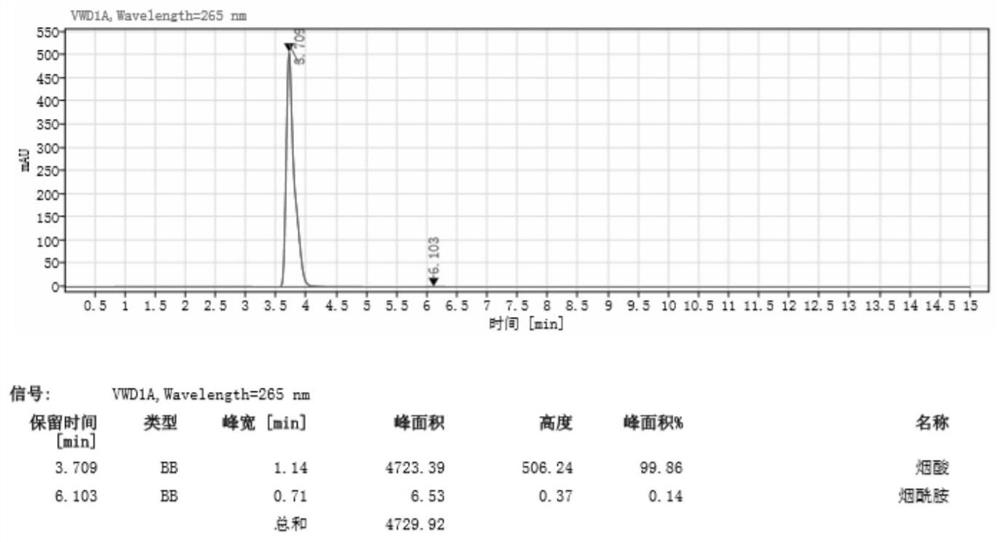

[0045] (4) Analysis: use hot water at a temperature of 75°C for analysis, with a flow rate of 2BV / hr, to obtain a niacin analysis solution, and sample T0;

[0046] (5) Resin regeneration: After the analysis is finished, feed 3 times column volume methanol solution, control flow rate 1BV / hr; Wash with water to pH7.0±0.5, control flow rate 2BV / hr;

[0047] (6) Concentrated crystallization: Concentrate the niacin analysis solution in step (4) by 15 times, add 4% activated carbon to the concentrated solution for decolorization, and then...

Embodiment 3

[0052] (1) Resin activation: Soak in methanol for 4 to 12 hours, treat with 4% (g / 100mL) NaOH solution, and wash with water;

[0053] (2) Wastewater pretreatment: get 4.0kg waste water and add 5% activated carbon of waste water quality to decolorize and filter;

[0054] (3) Adsorption on the column: the waste water in step (2) is adsorbed on the column with macroporous ion exchange resin Haipu HP334, and the flow rate is controlled at 1BV / hr;

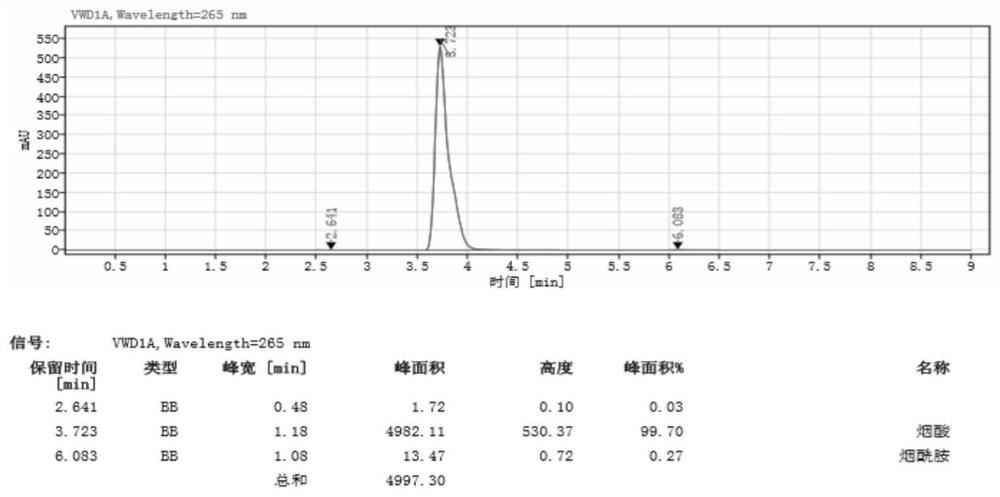

[0055] (4) Analysis: use hot water at a temperature of 80°C for analysis, with a flow rate of 2BV / hr, to obtain a niacin analysis solution, and sample T0;

[0056] (5) Resin regeneration: after the analysis is finished, feed 3 times column volume methanol solution, control flow rate 1BV / hr; Wash with water to pH7.0±0.5, control flow rate 1BV / hr;

[0057] (6) Concentrated crystallization: Concentrate the niacin analysis solution in step (4) by 10 times, add 5% activated carbon of the concentrated solution for decolorization, and then p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com