Preparation method of carbon-free permanent anti-static PVC coiled material

An anti-static, PVC resin technology, applied in the field of carbon-free permanent anti-static PVC coils, can solve the problems of disappearance, low volume resistivity, hardness increase, etc., achieve good fracture and tensile properties, and improve anti-static performance, the effect of reducing the resistance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

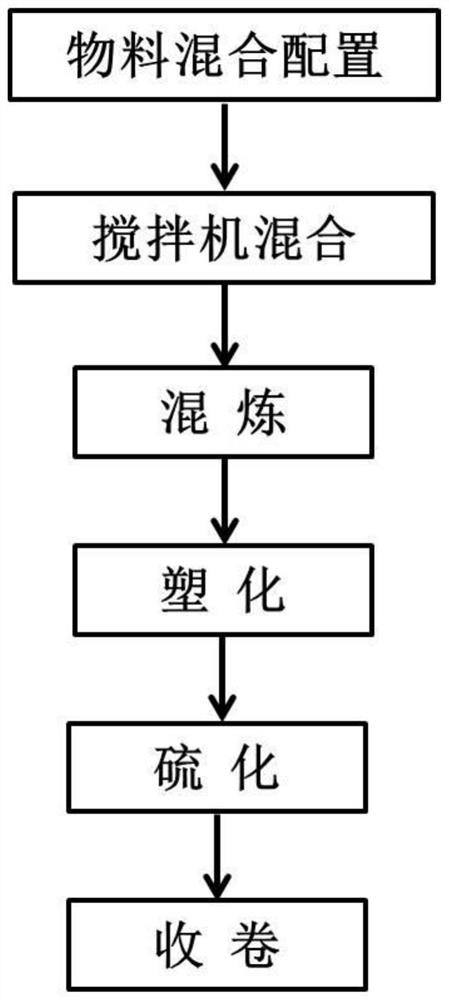

[0028] A kind of preparation method of carbon-free type permanent antistatic PVC coiled material, specifically comprises the following steps:

[0029] The composition comprises by weight: 100 parts of PVC resin, 30 parts of polyethylene-vinyl alcohol resin, 20 parts of polyaniline, 30 parts of bis(2-ethylhexyl) phthalate, 40106 parts of antioxidant, barium 3 parts of zinc composite stabilizer, 2 parts of trichlorofluoromethane, and 1.5 parts of metal organic framework material.

[0030] The preparation of the metal organic framework material comprises:

[0031] 1) Zinc nitrate, dimethylimidazole and p-hydroxybenzoic acid are added into the mixed solvent of ethanol and deionized water at a volume ratio of 6:1.5, wherein the mol ratio of zinc nitrate, dimethylimidazole and p-hydroxybenzoic acid is 0.5: 0.23:0.13, and then ultrasonically stirred to obtain a solution.

[0032] 2) Move the above solution into a high-pressure reactor, and then place it at 90° C. to react for 15 ho...

Embodiment 2

[0039] A kind of preparation method of carbon-free type permanent antistatic PVC coiled material, specifically comprises the following steps:

[0040] The ingredients include: 130 parts of PVC resin, 50 parts of polyethylene-vinyl alcohol resin, 35 parts of polyaniline, 45 parts of dioctyl phthalate, 26410 parts of anti-aging agent, 6 parts of barium-zinc composite stabilizer , 7 parts of dichlorodifluoromethane, and 3.5 parts of metal organic framework materials.

[0041] The preparation of the metal organic framework material comprises:

[0042] 1) Zinc sulfate, dimethylimidazole and p-hydroxybenzoic acid are added into the mixed solvent of ethanol and deionized water in a volume ratio of 6:2.8, wherein the mol ratio of zinc sulfate, dimethylimidazole and p-hydroxybenzoic acid is 0.5: 0.28:0.19, and then ultrasonically stirred to obtain a solution.

[0043] 2) The above solution was moved to a high-pressure reactor, and then placed at 100° C. for 24 hours to react to obtai...

Embodiment 3

[0050] A kind of preparation method of carbon-free type permanent antistatic PVC coiled material, specifically comprises the following steps:

[0051] The ingredients include by weight ratio: 110 parts of PVC resin, 40 parts of polyethylene-vinyl alcohol resin, 25 parts of polyaniline, 35 parts of butyl benzyl phthalate, 8 parts of antioxidant 4010na, 4 parts of barium-zinc composite stabilizer parts, 4 parts of dichlorotetrafluoroethane, and 2.5 parts of metal-organic framework materials.

[0052] The preparation of the metal organic framework material comprises:

[0053] 1) Zinc acetate, dimethylimidazole and p-hydroxybenzoic acid are added to a mixed solvent of ethanol and deionized water with a volume ratio of 6:1.8, wherein the molar ratio of zinc acetate, dimethylimidazole and p-hydroxybenzoic acid is 0.5 :0.25:0.16, and then ultrasonically stirred to obtain a solution.

[0054] 2) Move the above solution into a high-pressure reactor, and place it at 100° C. for 18 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com