Polysiloxane long-acting lubricating protective paint with space environment resistance

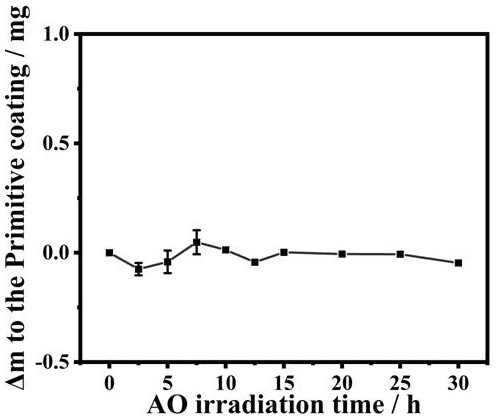

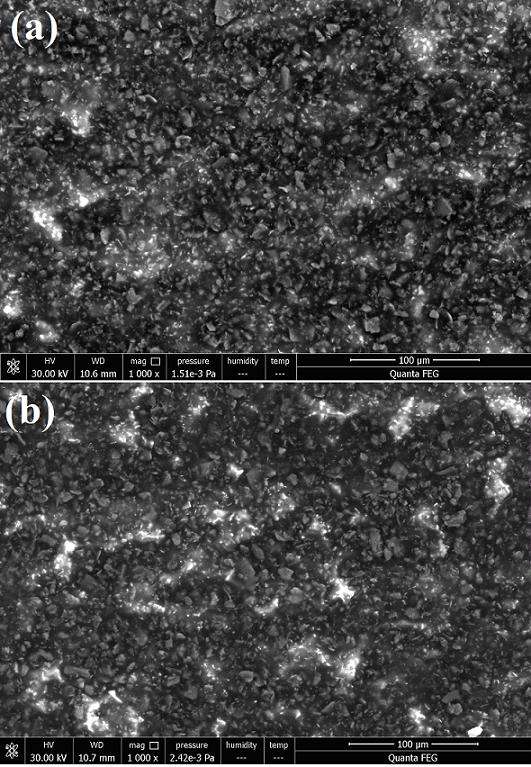

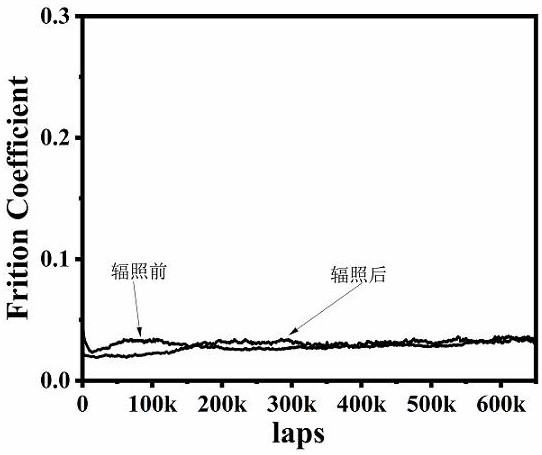

A technology of polysiloxane and protective coatings, applied in coatings and other directions, can solve the problems of large initial mass loss, easy lubrication failure, and reduced reliability of inorganic coatings after atomic oxygen irradiation, and achieve excellent space environment resistance, Solve the effect of low adhesion, improve space environment resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 A polysiloxane long-term lubricating protective coating with space resistance performance, the coating consists of 20g of epoxy-based polysiloxane resin, 18g of molybdenum disulfide slurry ground through a conical mill, 4,4 2 g of '-diaminodiphenyl sulfone is prepared by stirring at a speed of 2800r / min and dispersing evenly so that the solid content is 35±10%.

[0028] Wherein: epoxy-based polysiloxane resin refers to making by following method:

[0029] (1) Weigh according to the weight percentage of the following raw materials: 12g of γ-(2,3-glycidoxy)propyltrimethoxysilane, 6g of diphenyldimethoxysilane, 0.9g of dilute phosphoric acid with a mass concentration of 1% , absolute ethanol 20.55g, toluene 20.55g;

[0030] (2) Mix diphenyldimethoxysilane with diluent, heat to 65±5°C under oil bath conditions, then add dilute phosphoric acid, stir and hydrolyze at 65±5°C for 3 hours to obtain hydrolyzate;

[0031] (3) Add γ-(2,3-glycidoxypropoxy)propyltrimet...

Embodiment 2

[0032] Embodiment 2 A polysiloxane long-term lubricating protective coating with space-resistant environment performance, the coating consists of 20g of epoxy-based polysiloxane resin, 20g of molybdenum disulfide slurry ground through a conical mill, 4,4 6g of '-diaminodiphenyl sulfone was prepared by stirring at a speed of 3500r / min and dispersing evenly so that the solid content was 35±10%.

[0033] Wherein: epoxy-based polysiloxane resin refers to making by following method:

[0034] (1) Weigh according to the weight percentage of the following raw materials: 8g of γ-(2,3-glycidoxy)propyltrimethoxysilane, 8g of diphenyldimethoxysilane, 0.3g of dilute phosphoric acid with a mass concentration of 1% , absolute ethanol 1.85g, toluene 1.85g;

[0035] (2) Mix diphenyldimethoxysilane with diluent, heat to 65±5°C under oil bath conditions, then add dilute phosphoric acid, stir and hydrolyze at 65±5°C for 3 hours to obtain hydrolyzate;

[0036] (3) Add γ-(2,3-glycidoxypropoxy)pro...

Embodiment 3

[0037]Embodiment 3 A polysiloxane long-term lubricating protective coating with space resistance performance, the coating consists of 20g of epoxy-based polysiloxane resin, 10g of molybdenum disulfide slurry ground through a conical mill, 4,4 6g of '-diaminodiphenyl sulfone is prepared by stirring at a speed of 3000r / min and dispersing evenly so that the solid content is 35±10%.

[0038] Wherein: epoxy-based polysiloxane resin refers to making by following method:

[0039] ⑴Weigh according to the weight percentage of the following raw materials: 12g of γ-(2,3-glycidoxy)propyltrimethoxysilane, 11g of diphenyldimethoxysilane, 2.3g of dilute phosphoric acid with a mass concentration of 1% , absolute ethanol 9g, toluene 9g;

[0040] (2) Mix diphenyldimethoxysilane with diluent, heat to 65±5°C under oil bath conditions, then add dilute phosphoric acid, stir and hydrolyze at 65±5°C for 3 hours to obtain hydrolyzate;

[0041] (3) Add γ-(2,3-glycidoxypropoxy)propyltrimethoxysilane t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com