Super-amphiphobic composite coating capable of being repeatedly bonded and recycled as well as preparation and application thereof

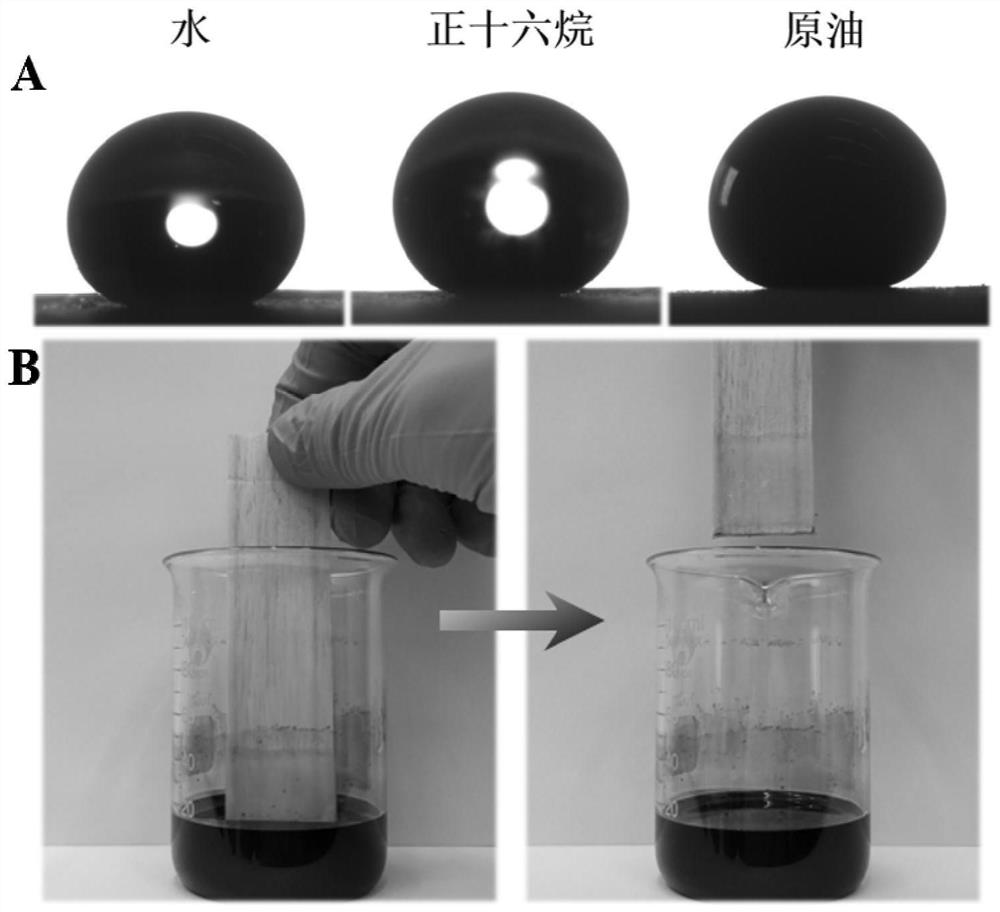

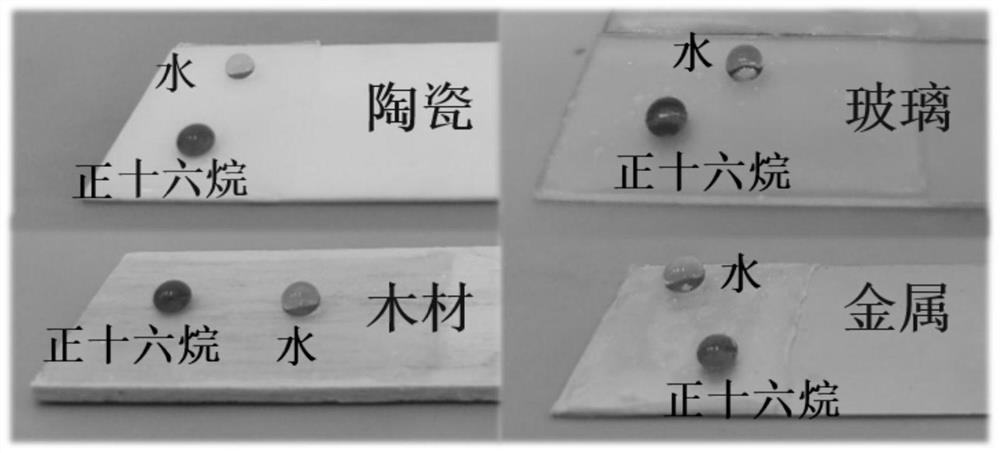

A composite coating and super-amphiphobic technology, applied in coatings, primers, etc., can solve substrate damage, the nano/micro roughness of the super-amphiphobic coating surface is easily damaged, and it is difficult to remove residues and adhesives and other issues, to achieve the effect of safety and high cost performance, excellent superhydrophobic and superoleophobic properties, and excellent anti-adhesion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The technical solutions of the present invention will be further described below in conjunction with specific examples.

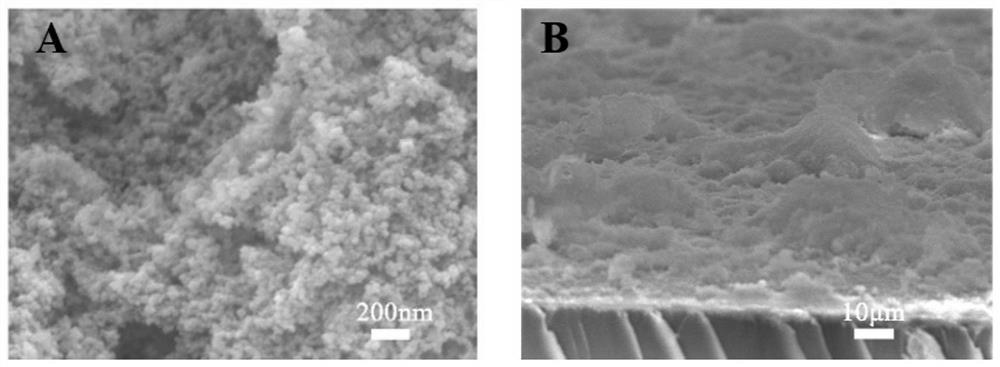

[0052] The invention provides a superamphiphobic composite coating, which comprises a viscous hydrogel primer layer and a superamphiphobic topcoat layer attached to the viscous hydrogel primer layer.

[0053] The preparation method of described super amphiphobic composite coating comprises the steps:

[0054] (1) Dissolving the hexamethylene diisocyanate trimer in anhydrous acetone to obtain a hexamethylene diisocyanate trimer solution. Ammonium persulfate (initiator, used in an amount of 1% of the total monomer mass) and acrylamide were added into deionized water to dissolve, and then hydroxyethyl methacrylate was dispersed into the acrylamide solution to obtain a monomer solution. Then mix the hexamethylene diisocyanate trimer solution with the monomer solution, add an accelerator (tetramethylethylenediamine, the dosage is 5% of the initiator dosa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com