Stone paper, calcium carbonate slurry and preparation methods of stone paper and calcium carbonate slurry

A technology of stone paper and calcium carbonate, applied in pulp beating/refining method, pulp raw material addition process, paper coating and other directions, can solve the problems of poor fluidity and dispersibility of calcium carbonate slurry, and meet the requirements of processing technology and viscosity. Controllable, good dispersion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

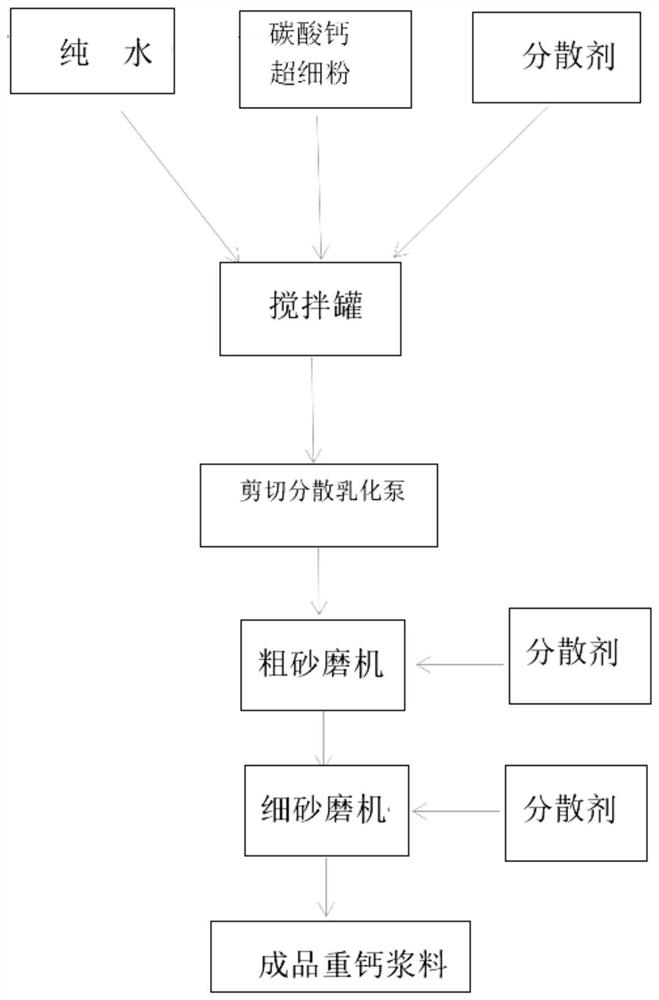

[0026] Such as figure 1 Shown, the embodiment of the present invention discloses a kind of grinding calcium carbonate slurry and preparation method thereof for stone paper coating, it comprises

[0027] Step 1 prepares superfine calcium carbonate powder with a particle size not greater than 6 μm;

[0028] In step 2, the calcium carbonate superfine powder is mixed and sheared and dispersed in a stirring tank to obtain an initial slurry, and the stirring speed is 800rpm / min;

[0029] Step 3: Grinding the initial slurry with a sand mill to obtain calcium carbonate slurry.

[0030] In this embodiment, precise control of the particle size, fineness, viscosity, etc. of the grinding slurry is achieved through the precise control of the stirring speed and the particle size of the ultrafine calcium carbonate powder. The obtained calcium carbonate slurry does not have adverse defects such as precipitation and coarse particles during long-term storage.

[0031] Ground calcium carbonat...

Embodiment

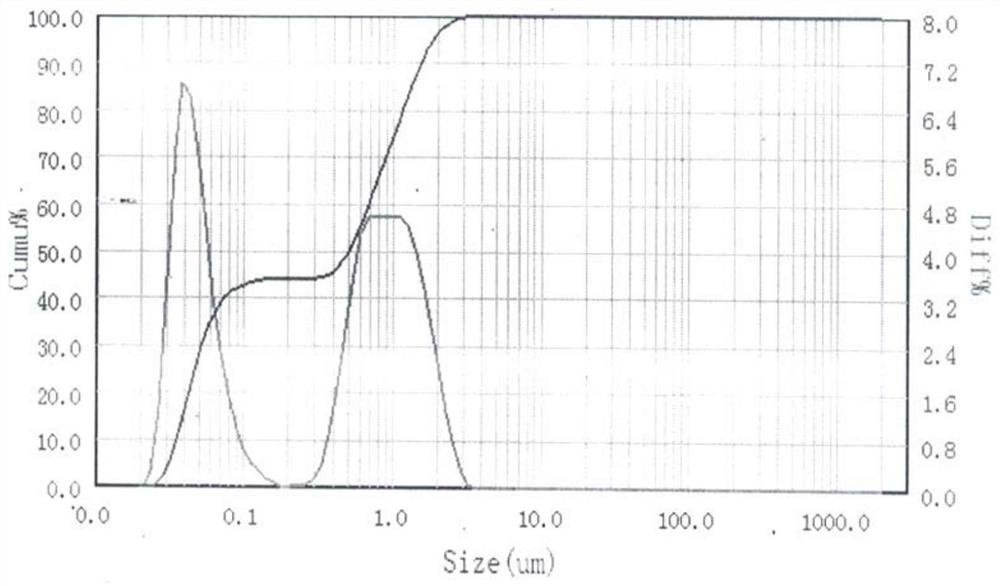

[0039] Use the dry method to grind the ultrafine powder intercepted after calcium carbonate classification to obtain ultrafine powder with a maximum particle size of no more than 6 μm, that is, calcium carbonate ultrafine powder; add water and dispersant in the mixing tank according to the designed slurry concentration, and stir After uniformity, slowly add calcium carbonate superfine powder, the stirring rotor in the mixing tank keeps running at high speed, so that the added powder has a good wetting and dispersing effect, and after stirring for 30 minutes, the preliminary pre-dispersion effect is obtained. Turn on the shear pump to further obtain good shear dispersion for the uniformly mixed slurry, and the stirring rotors run at the same time, and the shear time is controlled at 45min-60min. The sheared and dispersed slurry first enters the grinding stage of the coarse grinding process, and 0.15-0.3% dispersant is added according to the grinding viscosity and particle size i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com