Grain drying and cooling cylinder

A grain drying and cooling cylinder technology, applied in the agricultural field, can solve the problem of uneven drying and achieve the effect of uniform drying and fast cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

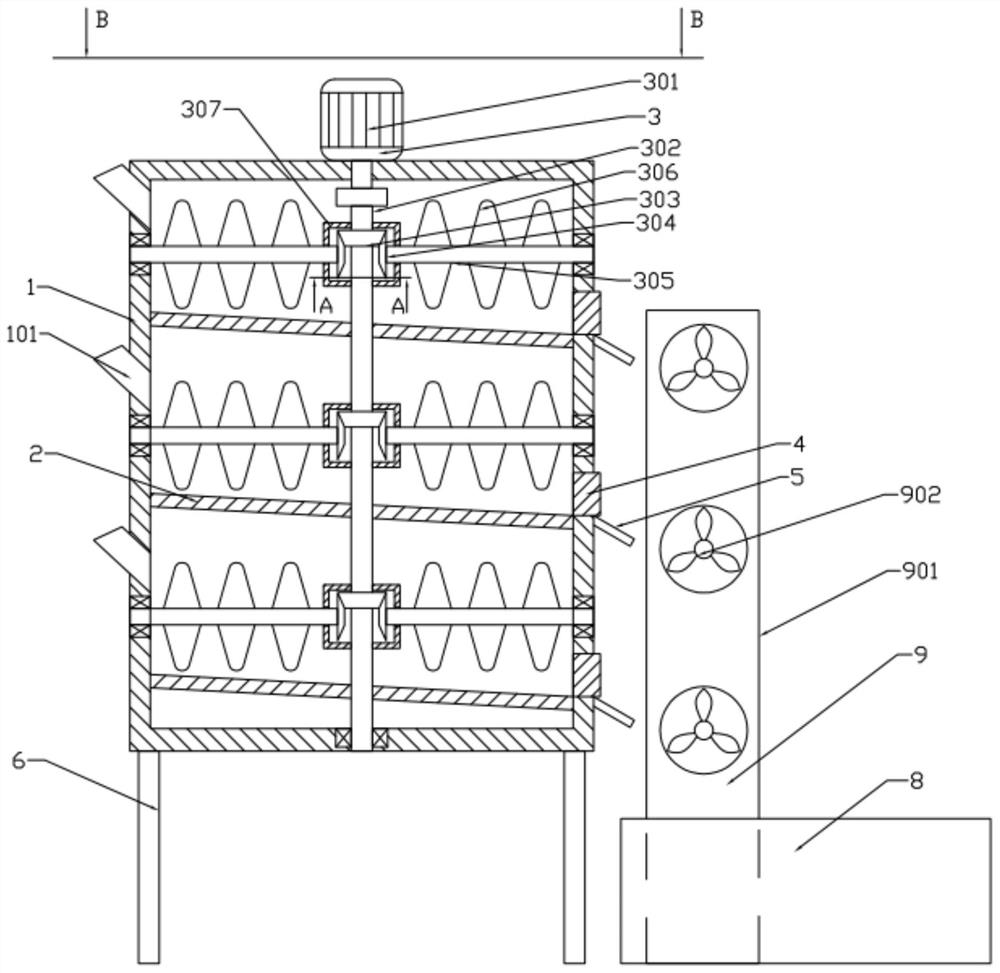

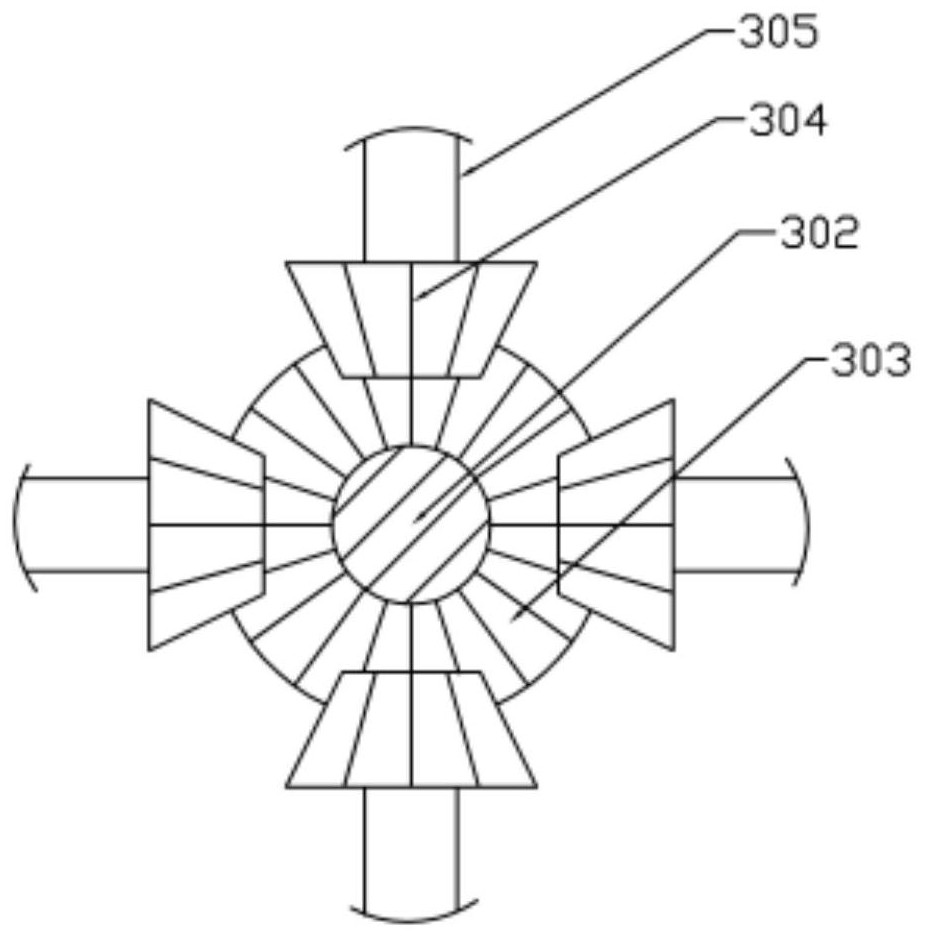

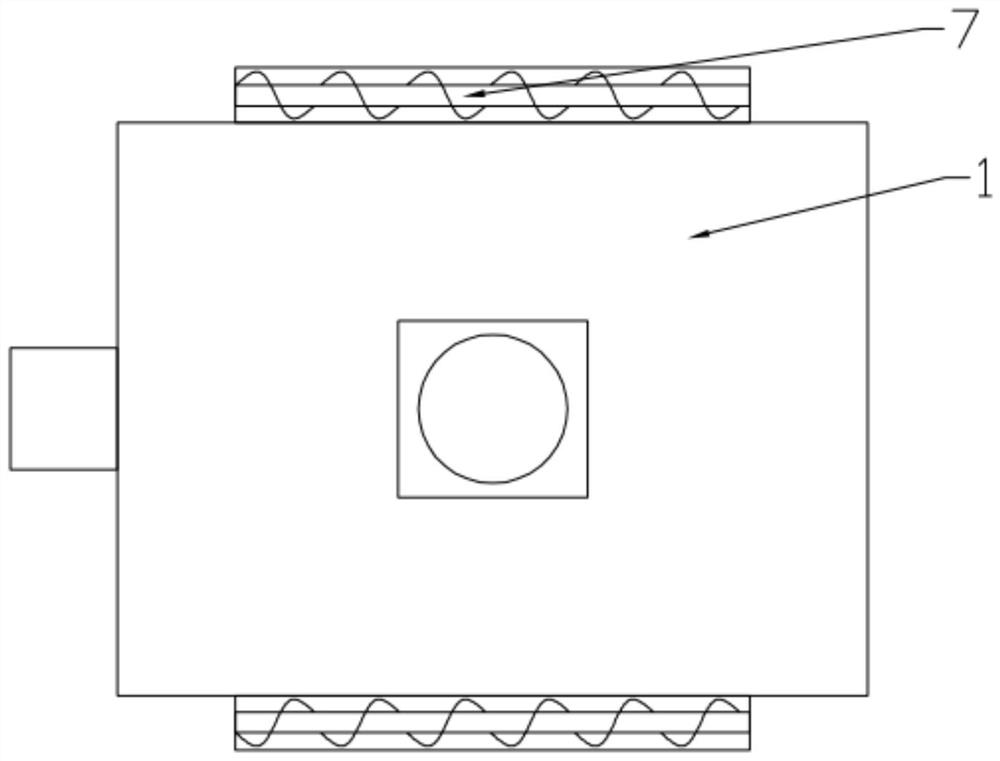

[0020] see Figure 1~3 , in an embodiment of the present invention, a grain drying and cooling cylinder includes a drying box 1, and three partition plates 2 are installed in the drying box 1, and the top of the three partition plates 2 is placed in the drying box. The left side of 1 is respectively provided with a feeding hopper 101, and the top of the drying box 1 is equipped with a turning mechanism 3 extending to the inside, and the turning mechanism 3 includes: a servo motor 301, a transmission shaft 302, a first cone Gear 303, second bevel gear 304, turning shaft 305, blade 306 and protective box 307, described servomotor 301 is installed on the top of drying box 1, the output shaft of described servomotor 301 passes shaft coupling and transmission shaft 302 Connected, three first bevel gears 303 are evenly distributed on the transmission shaft 302, and four second bevel gears 304 are installed on the underside of each first bevel gear 303 to rotate with it. The second ...

Embodiment 2

[0022] see figure 1 , in the embodiment of the present invention, the angle between the partition plate 2 and the horizontal plane is 5°.

[0023] When the grain drying and cooling cylinder is in use, the grain is respectively added into the drying box 1 from the three feeding hoppers 101, the heater 7 is started, the drive shaft 302 is driven by the servo motor 301 to rotate, and the drive shaft 302 is rotated to drive the first A bevel gear 303 rotates, rotates through the first bevel gear 303 and drives the second bevel gear 304 to rotate, rotates through the second bevel gear 304 and drives the turning shaft 305 to rotate, turns the blade 306 to rotate through the turning shaft 305, and rotates the grain through the blade 306. Stirring is conducive to more uniform drying; when the drying is over, the baffle plate 4 is removed, and the grain slides from the feeding chute 6 into the cooling box 8. Blow to cool.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap