Multi-chip packaging structure

A technology of multi-chip packaging and light-emitting chips, applied in the field of lighting, can solve the problems of difficult heat dissipation, large heat generation, high work efficiency, etc., and achieve the effects of improving mechanical strength, improving dispersion, and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

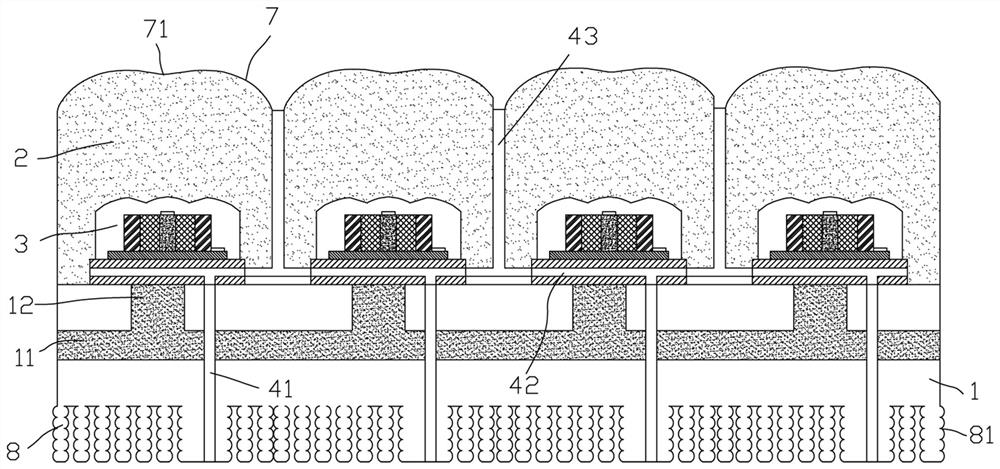

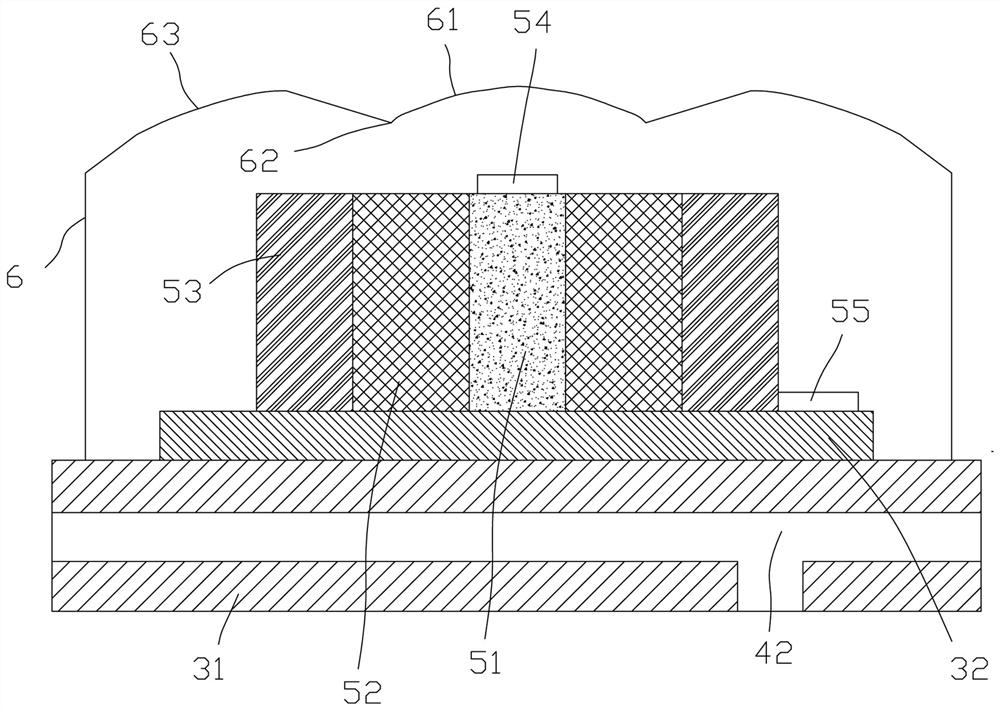

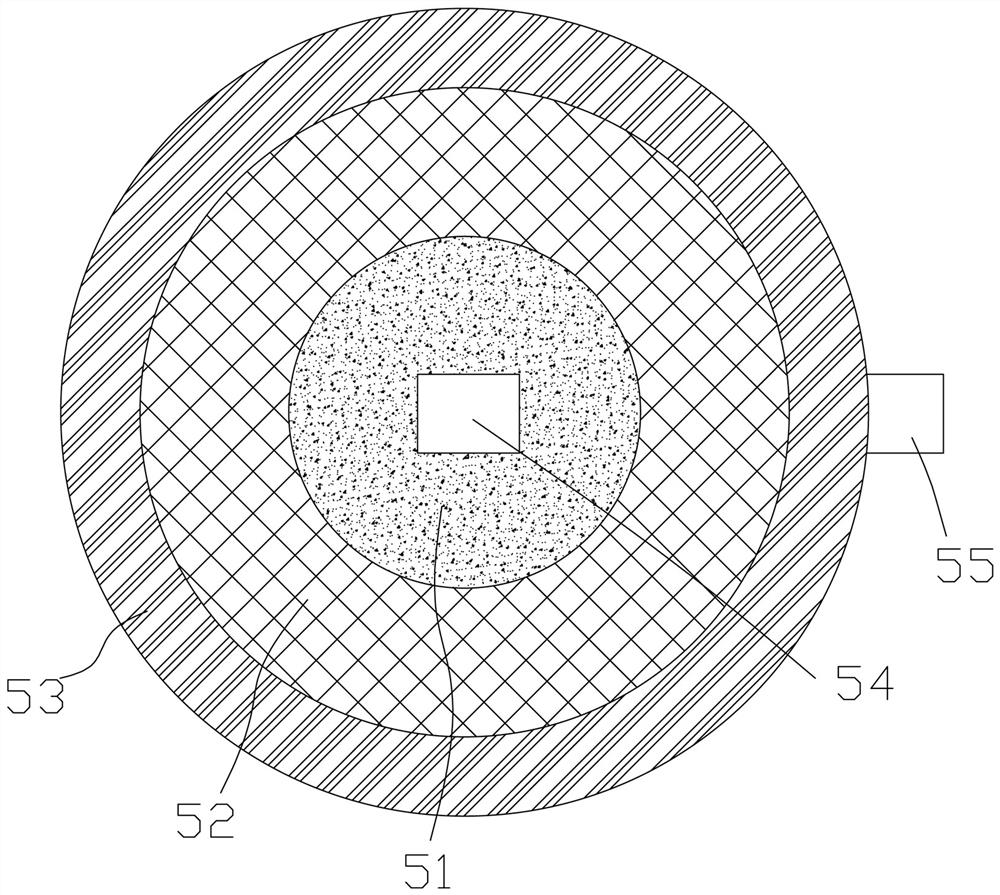

[0051]byFigure 1 to Figure 6 It can be seen that the multi-chip packaging structure described in this embodiment includes a heat dissipation base 1 and a package base 2 connected to the heat dissipation base 1; the package base 2 is provided with a plurality of light-emitting chips 3;

[0052]The heat dissipation base 1 is provided with a circulating water tank 11; the circulating water tank 11 is provided with cooling liquid; the heat dissipation base 1 is provided with a heat dissipation water tank 12 communicating with the circulating water tank 11; the heat dissipation water tank 12 is provided on the light emitting chip 3 bottom of;

[0053]The heat dissipation base 1 is provided with a first ventilation slot 41; the light-emitting chip 3 is provided with a second ventilation slot 42 communicating with the first ventilation slot 41; the packaging seat 2 is provided with a second ventilation slot 42 communicating with The third ventilation slot 43.

[0054]Specifically, in the multi-chip...

Embodiment 2

[0066]The difference between this embodiment and Embodiment 1 is that the package seat 2 is cured by a silicone potting glue, and the silicone potting glue includes the following raw materials in parts by weight:

[0067]A component

[0068]First end vinyl silicone oil 100 parts

[0069]Composite filler 40 parts

[0070]Hydrogen silicone oil 3 parts

[0071]MQ silicone resin 30 parts

[0072]Inhibitor 0.05 parts

[0073]B component

[0074]100 parts of vinyl silicone oil at the second end

[0075]MQ silicone resin 30 parts

[0076]0.2 parts of platinum catalyst;

[0077]Wherein, the weight ratio of the A component and the B component is 1:1;

[0078]Wherein, the composite filler is prepared by the following method:

[0079](1) Dehydrate and dry the nano-silica, then add toluene for ultrasonic dispersion for 20 minutes, add the silane coupling agent kh560, continue ultrasonic dispersion for 3 minutes, transfer to a three-necked flask with a reflux condenser, and heat up to 80°C After 5 hours of heat preservation and react...

Embodiment 3

[0087]The difference between this embodiment and Embodiment 1 is that the package seat 2 is cured by a silicone potting glue, and the silicone potting glue includes the following raw materials in parts by weight:

[0088]A component

[0089]First end vinyl silicone oil 100 parts

[0090]Composite filler 50 parts

[0091]Hydrogen silicone oil 6 parts

[0092]MQ silicone resin 40 parts

[0093]Inhibitor 0.1 part

[0094]B component

[0095]100 parts of vinyl silicone oil at the second end

[0096]MQ silicone resin 40 parts

[0097]0.4 parts of platinum catalyst;

[0098]Wherein, the weight ratio of the A component and the B component is 1:1;

[0099]Wherein, the composite filler is prepared by the following method:

[0100](1) Dehydrate and dry the nano-silica, then add toluene for ultrasonic dispersion for 30 minutes, add silane coupling agent kh560, continue ultrasonic dispersion for 5 minutes, transfer to a three-necked flask with reflux condenser, and heat up to 90°C After heating for 7 hours, centrifugal separation af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com