Novel lithium battery and manufacturing process and application thereof

A manufacturing process, lithium battery technology, applied in lithium batteries, batteries, secondary batteries, etc., can solve problems such as high-intensity vibration, inability to meet the application requirements of power tools, and inability to meet the requirements of impact drills, etc., to improve the expansion and contraction ability. , Solve the hidden danger of short circuit and improve the effect of wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

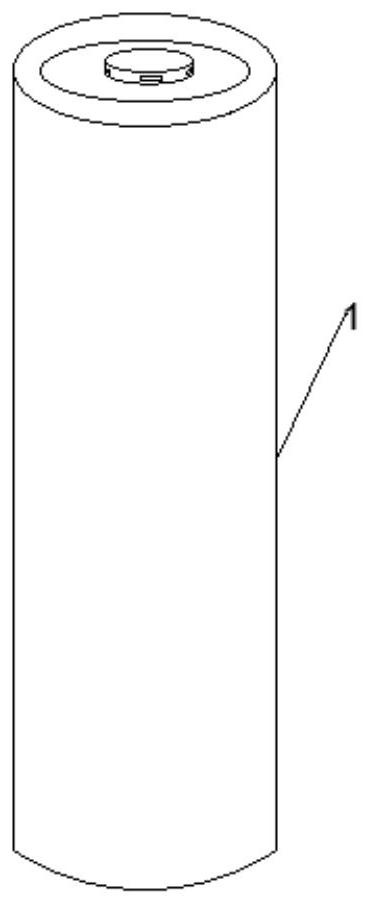

[0034] A new type of lithium battery, including a battery body 1, the battery body 1 is cylindrical, its diameter d is: 18≤d<21mm, and its height h≥650mm, specifically d can be 18mm, 18.1mm, 19mm, 20mm, h can be 650mm, 700mm, 750mm.

[0035] In this embodiment, by arranging batteries of different sizes, the capacity thereof will be correspondingly improved. Therefore, the performance of the conventional battery is improved, and at the same time, the performance application of the electric capacity on the electric tool is satisfied.

[0036] As the first embodiment of the present invention, it also has the following additional technical features:

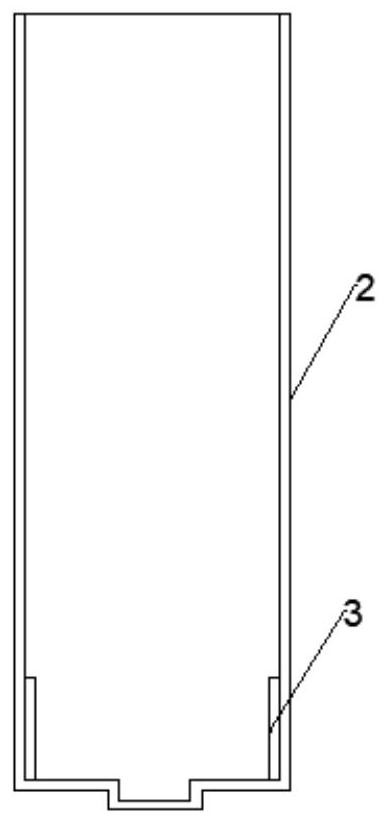

[0037] The battery main body 1 includes a casing 2, a battery core disposed in the casing 2, and an electrolyte filled in the casing 2. The bottom cavity of the casing 2 is integrally formed with a clasp 3, which enables the battery core to When the body is loaded, it just snaps into the snap ring, and there is no room for vibration...

no. 2 example

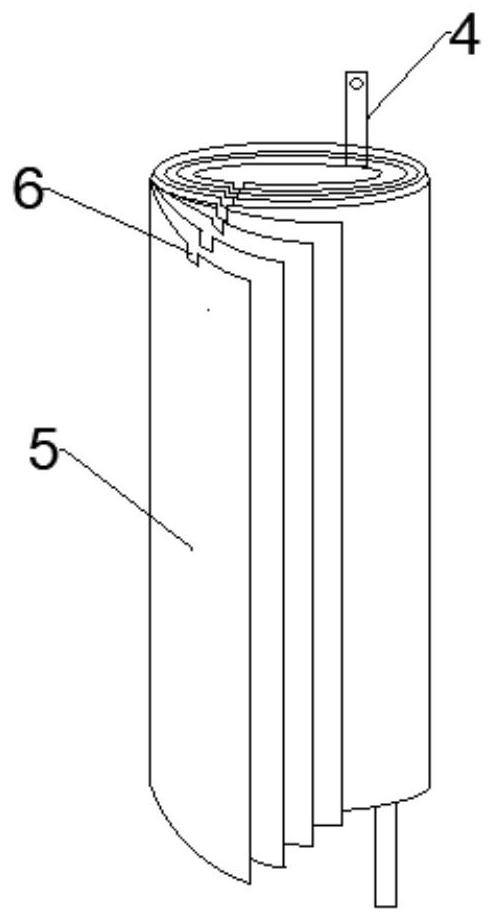

[0043] The present invention also provides a second embodiment: a manufacturing process of a new type of lithium battery, including sheet making, winding, shaping, battery casing, and liquid injection packaging, wherein the sheet making includes the following steps; Or coating a glue mesh layer 7 continuously or at intervals on the negative electrode sheet, the glue mesh layer includes the following raw materials: matrix glue and porous inorganic carbon material, porous carbon material in the matrix glue, on the one hand has abundant pore structure, has The heat storage capacity can effectively solve the thermal runaway effect of the battery. On the other hand, its rich pore structure can make the surface of the coated glue quickly pass the electrolyte through the pore structure to wet the surface of the pole piece.

[0044] The base glue is a thermoplastic elastomer.

[0045] The raw material also includes a flame retardant, which can also improve the safety performance of th...

Embodiment 1

[0048]A manufacturing process for a new type of lithium battery, including sheet making, winding, shaping, and battery casing and liquid injection packaging, wherein the sheet making includes the following steps: coating a glue net layer 7 on the positive electrode sheet and / or the negative electrode sheet , the glue mesh layer includes the following raw materials in parts by weight: 90 parts of matrix glue and 10 parts of porous inorganic carbon material. The matrix glue is a thermoplastic elastomer, specifically thermoplastic polyurethane elastomer, and the porous inorganic carbon material is activated carbon. The raw material also includes 1 part of flame retardant, which is triphenyl phosphate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com