Preparation method of special catalyst for nitrobenzene hydrogenation production of p-aminophenol

A technology for p-aminophenol and a preparation method, applied in the chemical industry, can solve the problems of fast catalyst consumption, poor selectivity, restricting the profitability of enterprises, etc., so as to reduce material costs and waste water treatment costs, reduce catalyst consumption, and improve hydrogenation reaction. The effect of the condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

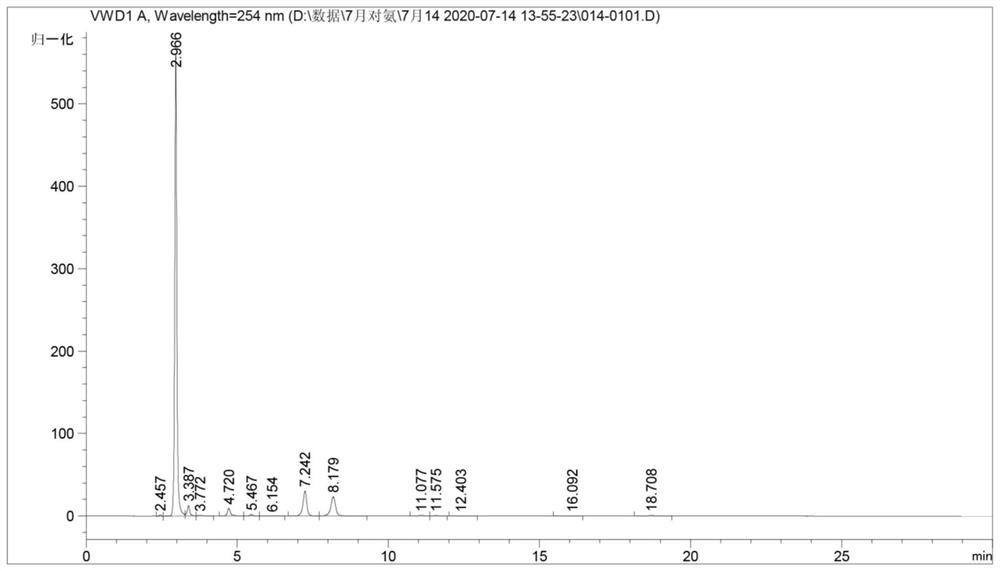

Examples

Embodiment 1

[0023] This embodiment discloses a preparation method of a special catalyst for producing p-aminophenol by hydrogenation of nitrobenzene, comprising the following steps:

[0024] S1. Pretreatment of coconut shell activated carbon

[0025] Add 2000g of coconut shell activated carbon to 4000mL of pure water, add 2000mL of 10% nitric acid under stirring, heat to 90°C, keep warm for 30min, cool and filter, and wash with pure water until neutral;

[0026] S2. Making Pt / C catalyst

[0027] Add the pretreated coconut shell activated carbon into 108mL of 10% aqueous solution of chloroplatinic acid, raise the temperature to 90-95°C, keep it warm for 20-40min; cool down to 60-70°C, add sodium carbonate while stirring, and adjust to alkali Add 200mL of 37% formaldehyde solution, then raise the temperature to 90°C, keep the pH value in the range of 9-10, keep it warm for 2.5 hours, then cool, filter, and fully wash until neutral;

[0028] S3. Add modifier

[0029] Add 0.4g of silver ni...

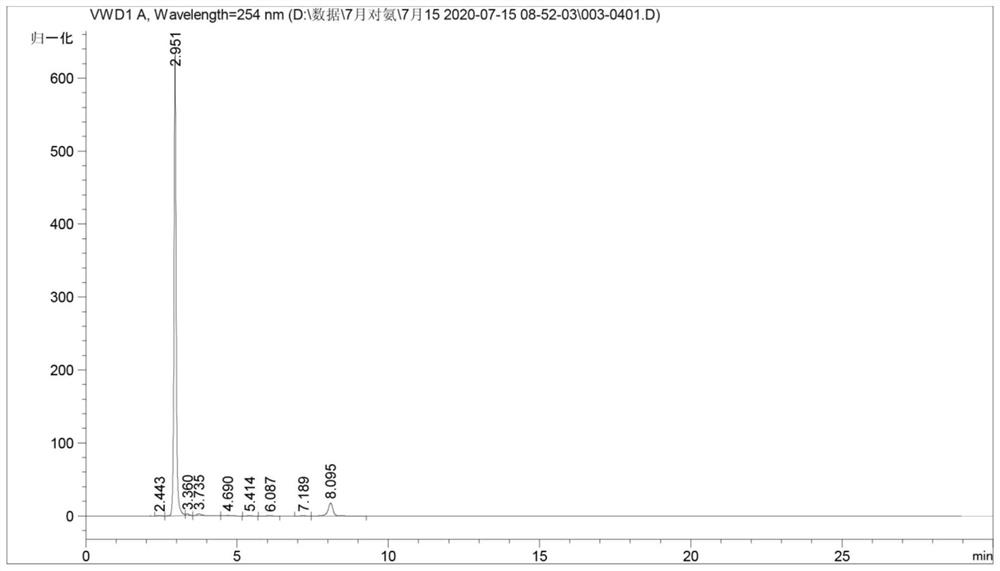

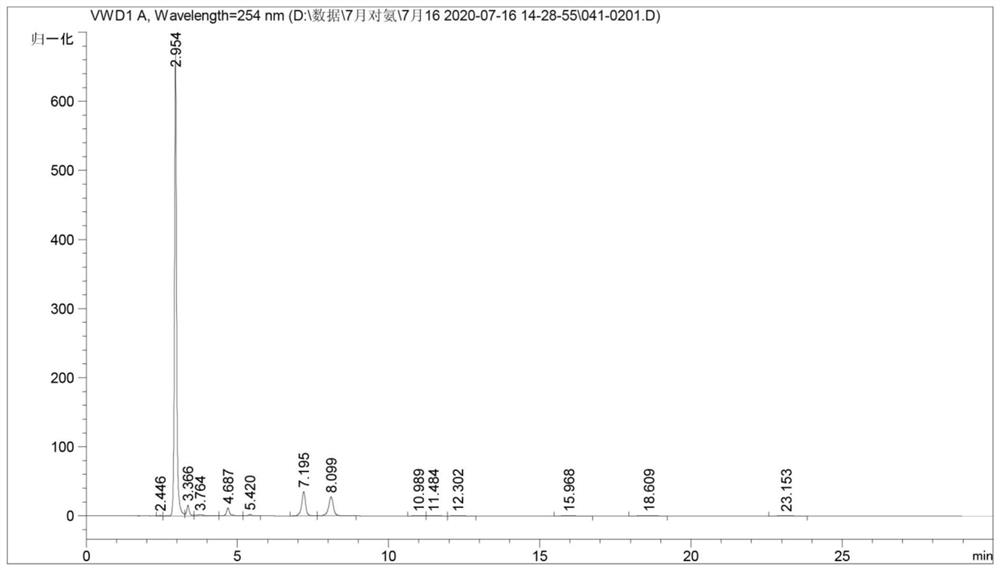

Embodiment 2

[0031] This embodiment discloses a preparation method of a special catalyst for producing p-aminophenol by hydrogenation of nitrobenzene, comprising the following steps:

[0032] S1. Pretreatment of coconut shell activated carbon

[0033] Add 2000g of coconut shell activated carbon to 4500mL of pure water, add 1500mL of 10% nitric acid under stirring, heat to 90°C, keep warm for 30min, cool and filter, and wash with pure water until neutral;

[0034] S2. Making Pt / C catalyst

[0035] Add the pretreated coconut shell activated carbon into 135mL of 8% chloroplatinic acid aqueous solution, raise the temperature to 90-95°C, and keep it warm for 20-40min; cool down to 60-70°C, add sodium carbonate while stirring, and adjust to alkali Add 300mL of 37% formaldehyde solution, then raise the temperature to 90°C, keep the pH value in the range of 9-10, keep it warm for 2.5 hours, then cool, filter, and fully wash until neutral;

[0036] S3. Add modifier

[0037] Add 0.6 g of silver n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com