Laser processing device

A laser processing and laser technology, applied in metal processing, laser welding equipment, metal processing equipment, etc., can solve problems such as damage to the luminescent layer, uneven laser processing of scanner operating frequency, disordered spot spacing, etc., to promote grinding processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

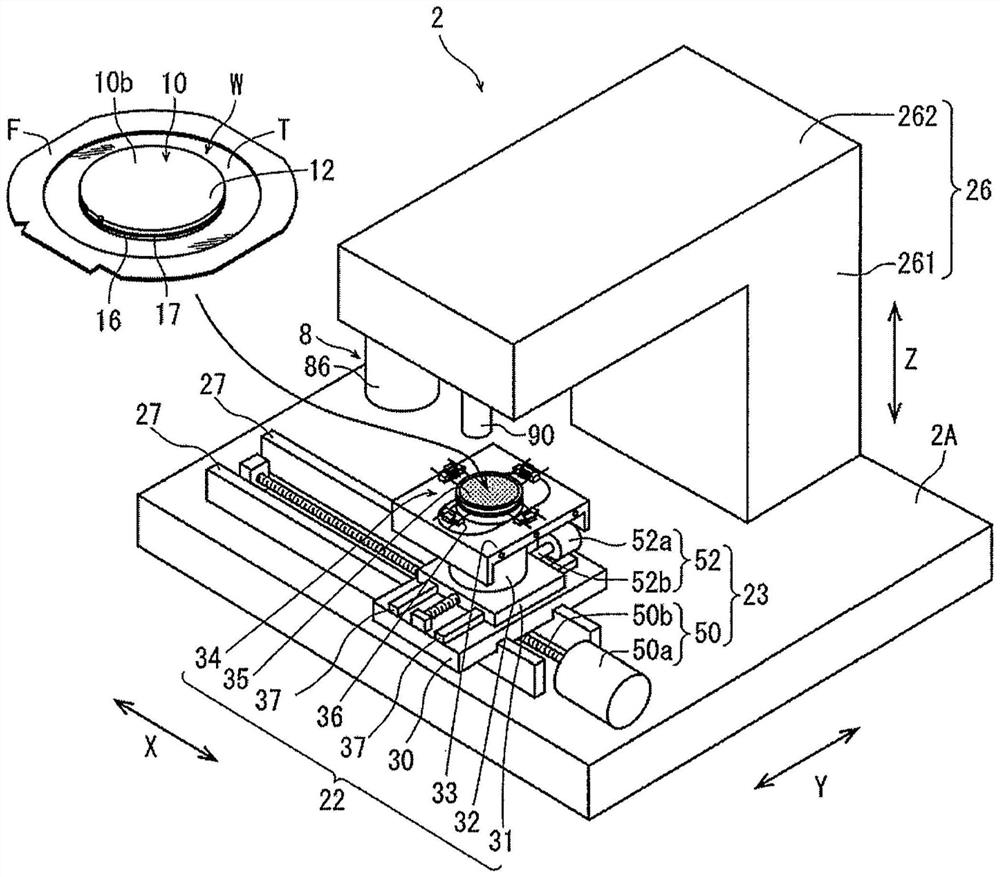

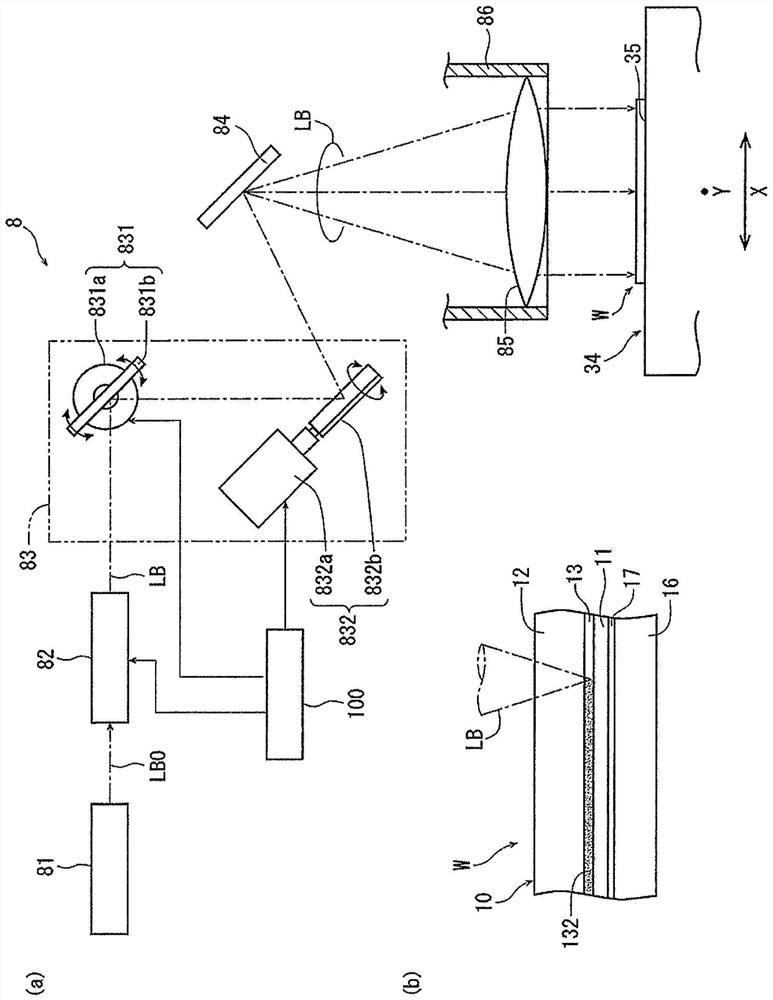

[0022] Hereinafter, a laser processing apparatus according to an embodiment of the present invention will be described in detail with reference to the drawings.

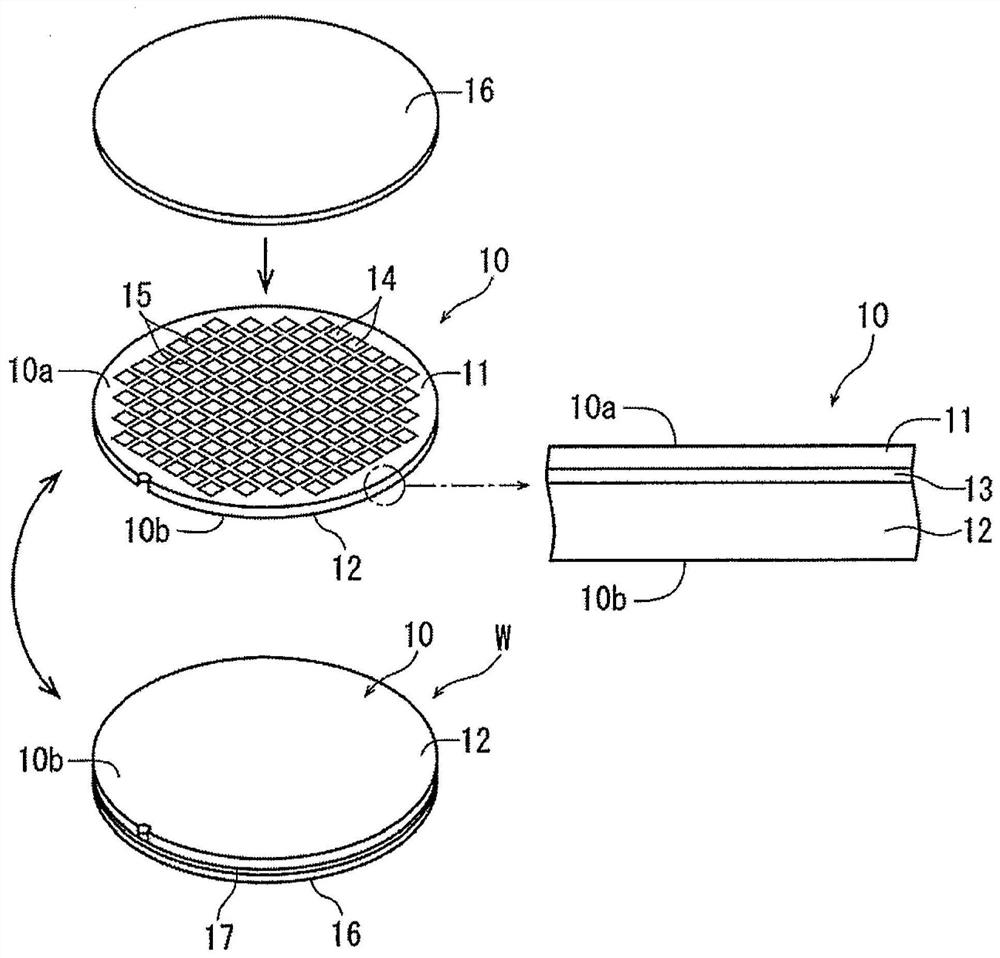

[0023] exist figure 1 2 shows a perspective view of a laminated wafer W, which is a workpiece to be processed by laser processing in the laser processing apparatus of the present embodiment, and is composed of a light-emitting wafer 10 and a transfer substrate 16 .

[0024] by figure 1 It can be understood that the light-emitting wafer 10 has a light-emitting layer 11 and a buffer layer 13 formed by epitaxial growth on the front surface of a sapphire substrate 12 prepared as an epitaxial substrate. The light-emitting layer 11 is composed of, for example, an n-type gallium nitride semiconductor layer, a p-type gallium nitride semiconductor layer, and a suitable conductor pattern (not shown), such as figure 1 As shown, LED14 is formed in the several area|regions divided by the some planned dividing line 15 formed in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com