Waste heat recovery device for methanol production

A waste heat recovery device, methanol technology, applied in the fields of organic chemistry, chemical instruments and methods, climate sustainability, etc., can solve the problems of heat loss, long production time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

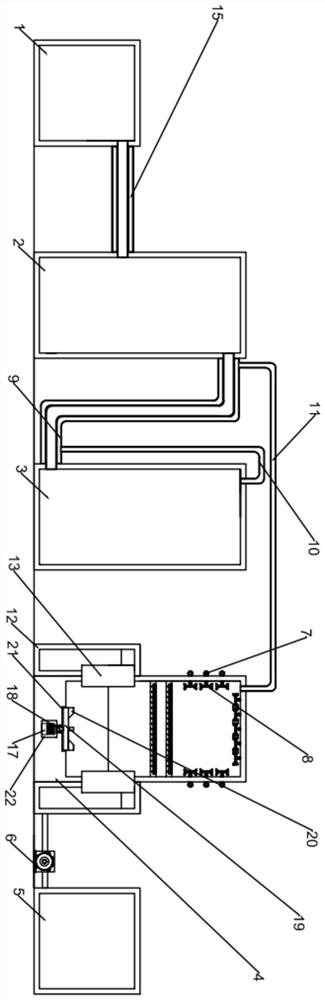

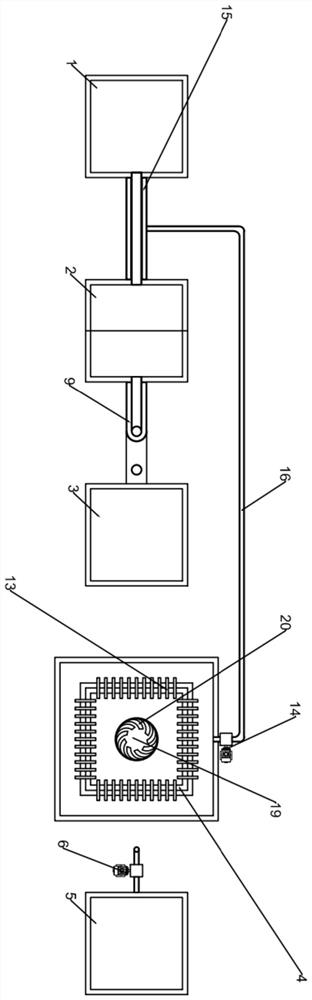

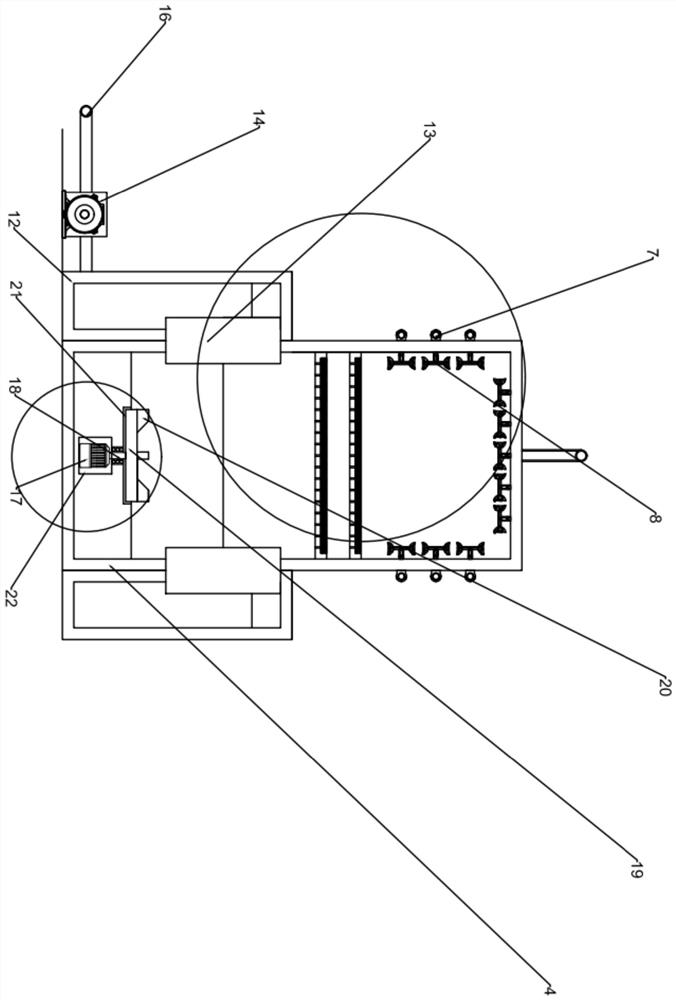

[0029]Embodiment: By pumping the liquid in the raw material water tank 1 into the carbon-water mixing tower 2, mixing water and coal at high temperature to form a coal mixed gas, leading the coal mixed gas into the synthesis tower 3, and mixing the coal mixed gas with high temperature The high temperature is converted into methanol gas, and the methanol gas is diverted into the mixed gas preheating sleeve 9 through the synthetic carbon water drainage tube 10, and the raw coal mixed gas is preheated by the methanol gas in the mixed gas preheating sleeve 9, and the methanol gas is The heat in the coal is transferred to the mixed gas of raw material coal, thus avoiding the loss of heat, the methanol gas is diverted into the cooling tower 4 through the carbon water cooling drainage pipe 11, and the neutralized liquid in the cooling mixed liquid tank 5 is pumped through the cooling pump 6 Into the drainage shunt pipe 7, through the drainage shunt pipe 7, the neutralization liquid is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com