Method for preventing loss of filter material during back washing of biological aerated filter (BAF)

A biological aerated filter, biofilter technology, applied in the direction of biological treatment devices, sustainable biological treatment, chemical instruments and methods, etc., can solve problems such as improper control of suspended solids, blockage of filter material layer, rise in filter pressure, etc. , to achieve the effect of solving the problem of filter material compaction, ensuring the operation cycle and improving the processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

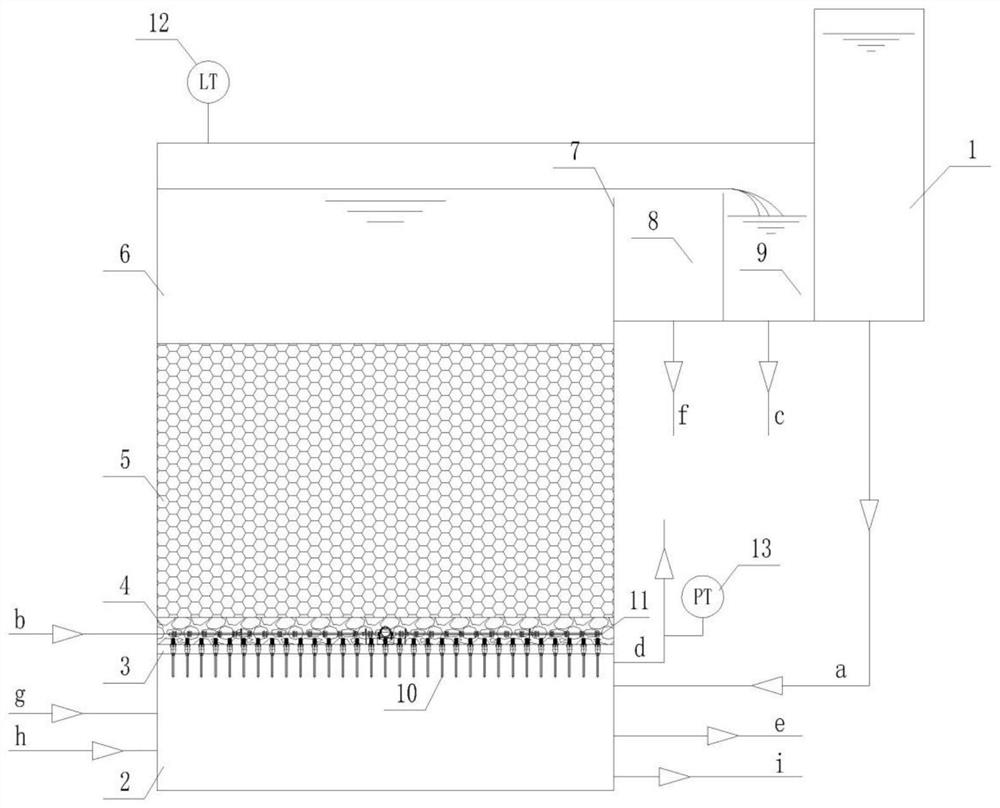

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

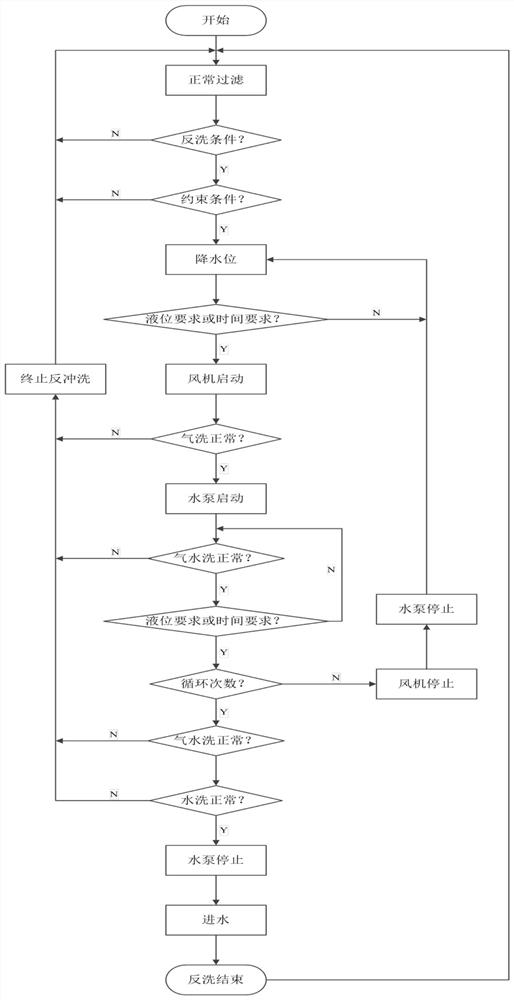

[0032] When the automatic control system starts to start the backwashing program, use the precipitation level backwashing-air washing-air-water combined backwashing-repeat 2-4 times the above sequential steps of precipitation level backwashing, air washing, air-water combined backwashing-water rinsing method Backwash the biological aerated filter (BAF), and the specific steps of backwashing to prevent the loss of filter material are:

[0033] 1) Precipitation level backwash: first close the valve on the normal inlet pipe a of the filter, the aeration system 11 (when the biological aerated filter is an aerobic biological filter), open the valve on the backwash drainage pipe f; turn on the precipitation The valve on the level pipeline e reduces the liquid level in the filter tank to the surface of the filter material layer 5, and the water volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com