Control system and control method of reverse osmosis membrane water purification equipment

A technology of water purification equipment and reverse osmosis membrane, which is applied in the general control system, control/regulation system, osmosis/dialysis water/sewage treatment, etc. It can solve the problems that cannot be automatically monitored and processed, and achieve high reliability and automation Level, prolong working life and reduce workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

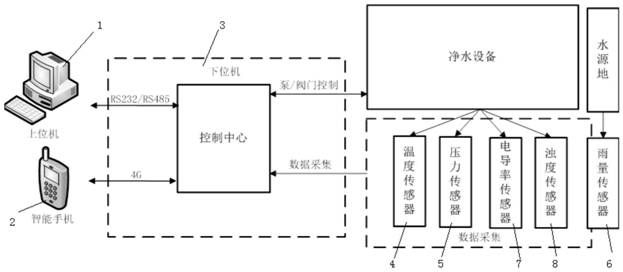

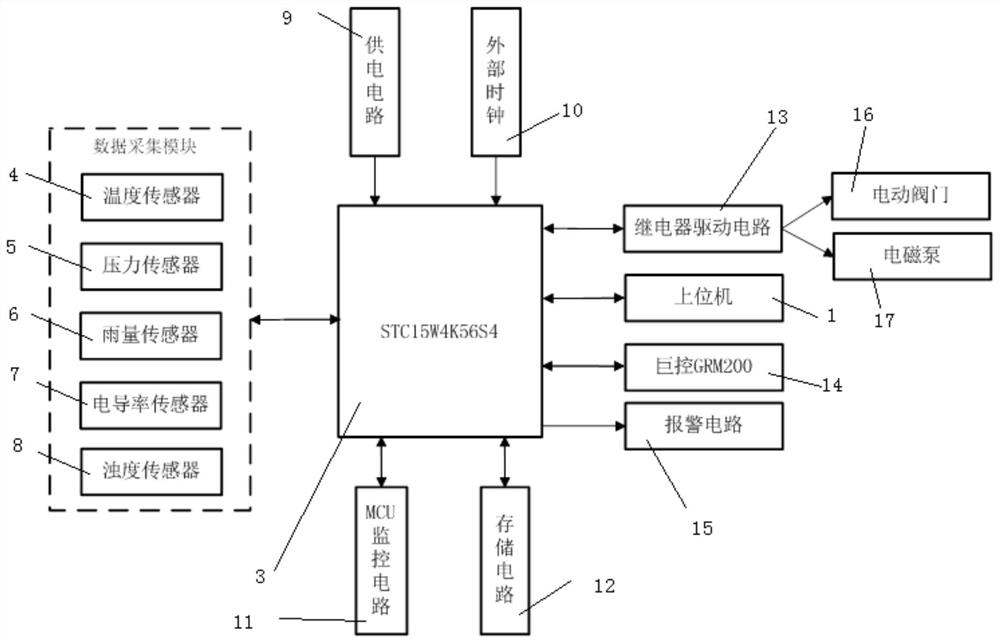

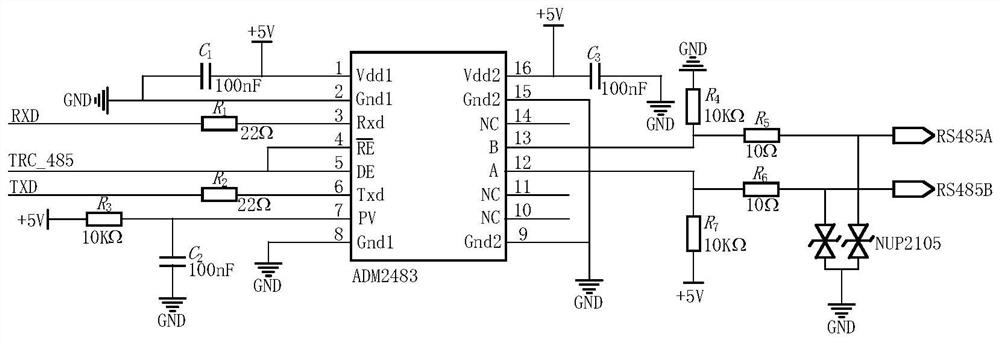

[0027] A control system of reverse osmosis membrane water purification equipment in this embodiment, such as figure 1 As shown, its composition includes an upper computer 1, a mobile phone 2, a lower computer 3, and a data acquisition module. Among them, the upper computer 1 is the computer on site of the water purification equipment, and the staff can realize user registration, user login, and threshold setting through the upper computer 1. , Check the work status and other operations. On the one hand, the various environmental parameters of the water purification equipment and the rainfall of the water source are collected and transmitted to the host computer 1; The upper computer 1 communicates with the lower computer 3 through the bus; according to the requirements of different sites, the lower computer 3 reserves two RS232 and two RS485 bus communication interfaces, and the staff can choose the appropriate interface for communication according to the actual situation. In...

specific Embodiment approach 2

[0031] The difference from Embodiment 1 is that in the control system of a reverse osmosis membrane water purification equipment in this embodiment, the temperature sensor 4 is a platinum resistance temperature sensor 4STT-BPA1B6C300D1E3N2G1PBT2S0; the present invention adopts a reverse osmosis membrane process, when When the temperature changes, the shape of the RO membrane changes, the viscosity of the water body changes, and the surface tension changes. These factors will indirectly affect the membrane flux. With 25 degrees Celsius as the suitable working temperature, every time the temperature drops by 1 degrees Celsius, the water production will drop by 3%. Real-time monitoring of water temperature provides a better understanding of how the entire system is functioning.

specific Embodiment approach 3

[0033] The difference from Embodiment 1 is that in the control system of reverse osmosis membrane water purification equipment in this embodiment, the pressure sensor 5 is a KAP50 capacitive pressure transmitter. It is used to monitor the inlet and outlet water pressure and liquid level, and shut down the equipment when the inlet water pressure is too low to prevent the booster pump from being burned out. When the water in the water storage tank is nearly full, the device is put into standby mode to prevent the water storage tank from overflowing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com