Method for extracting product data characteristics in batches by using matrix generalized inverse

A product data, batching technology, applied in database indexing, electronic digital data processing, structured data retrieval and other directions, can solve the problems of waste of data resources, large amount of calculation, analysis of factors affecting model update, etc., to achieve dimensionality reduction and Noise filtering, the effect of controlling the amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] In the process of robot electric welding, before all welding, there will be a teaching program recorded according to manual welding. This teaching program has been repeatedly tested by engineers and is the optimal state that can be achieved before formal production. However, after it is actually connected to the production line, under long-term continuous work, the machine and manufacturing materials will gradually change, resulting in a decline in welding quality. The solution is as follows:

[0083] Step 1. Before performing teaching welding, use a data set with a moderate number, generally no more than 10,000, to build a basic model. The parameters of this basic model are not only collected from the data of small-scale experiments, but also from some data that have been actually launched in the past to form the basic model.

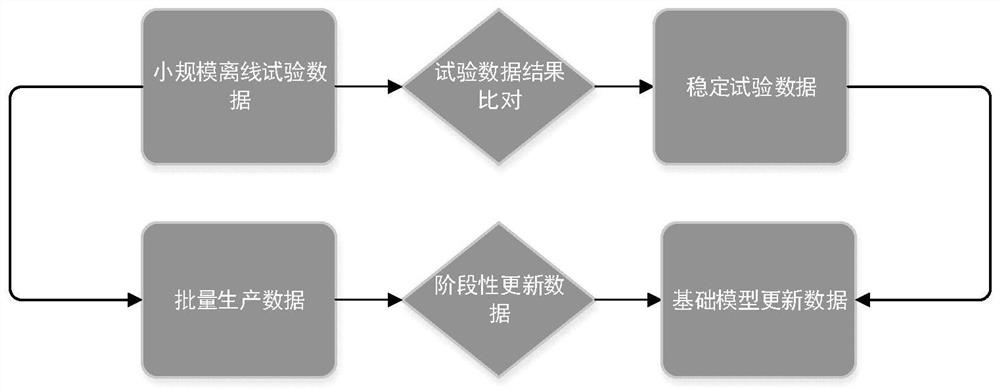

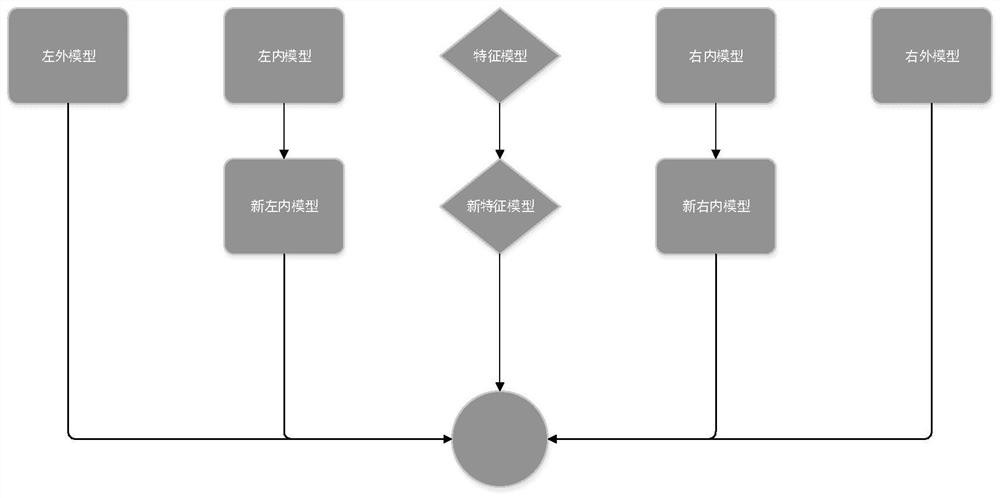

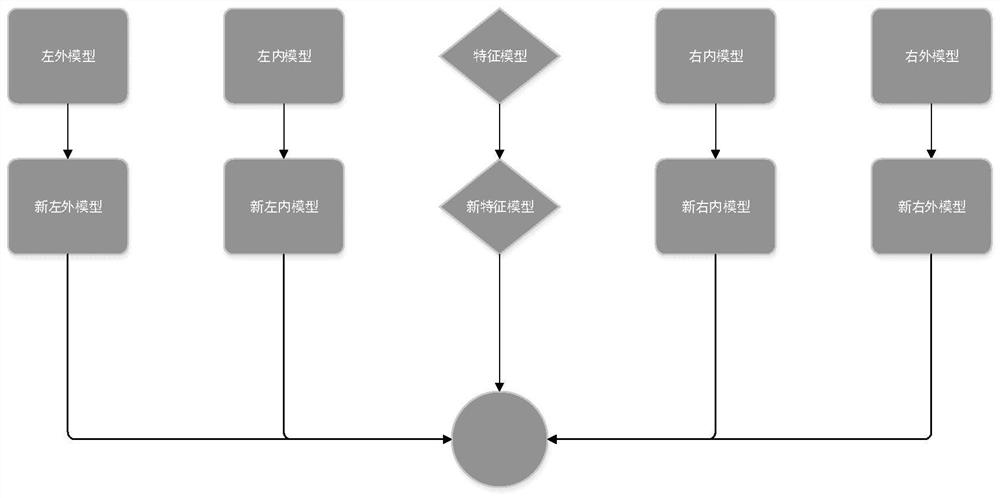

[0084] Step 2. In the basic model, for the data from the small-scale experiment part, it is determined as the part of the stock model, and for ...

Embodiment 2

[0091] In the glass production process, the initial parameter design should be carried out according to the laboratory test first, and then enter into batch production. However, the collection of intermediate data in the intermediate process of glass production is very troublesome, and the entire production is in a process of constant change, so a process system that can be continuously adjusted according to the production process is required.

[0092] Step 1: Before entering the batch production of glass, conduct small-scale experiments, and then collect the parameters of the small-scale experiments as the basic parameters of the model; at the same time, collect a part of the original batch production data, which will be used as the updated parameter part of the model. The combination of the two forms the basic model, and the data scale of the basic model is more than 10,000.

[0093] The second step is to perform feature extraction on the data of the small-scale test and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com