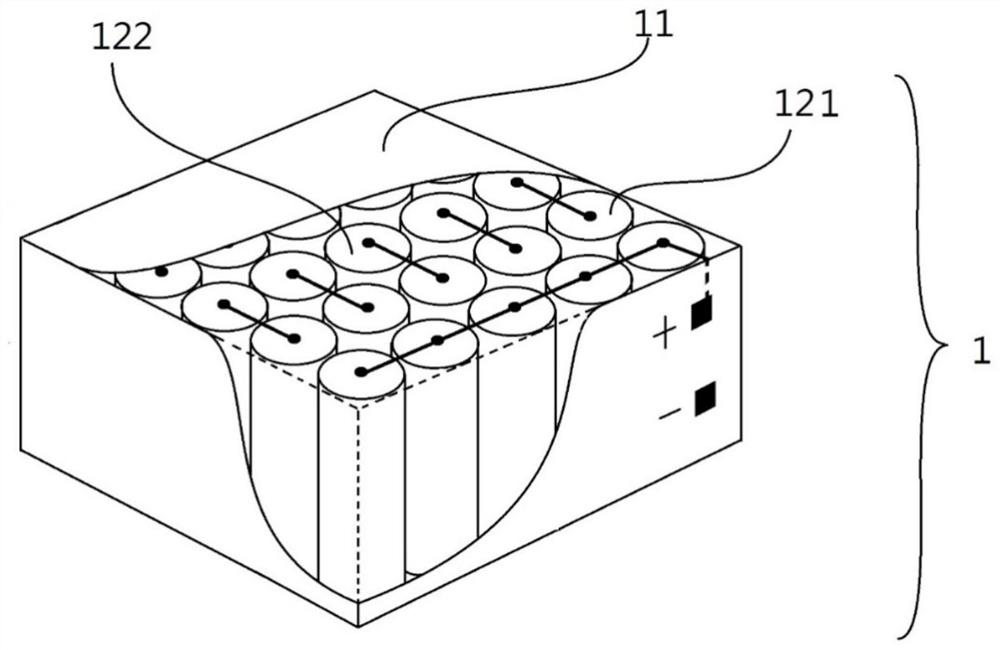

High-stability heat dissipation battery pack structure

A high-stability battery pack technology, applied in secondary batteries, structural parts, battery pack components, etc., can solve the problems of low heat dissipation efficiency, poor temperature consistency, and low safety of battery cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

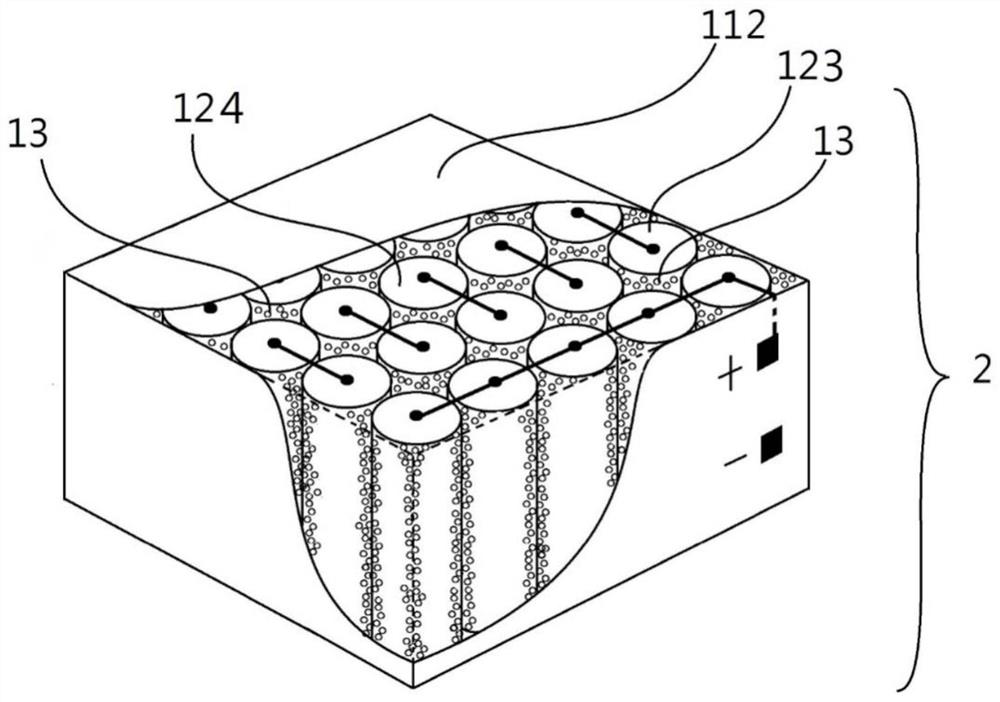

[0040] Composite phase change materials are used to meet the needs of batteries, and the temperature of the phase change point is 65°C, and the insulation resistance is >10 10 Ω, thermal conductivity of 1.0 (W / K·M), latent heat value of 130 (J / g).

[0041] In this composite phase change material, the content is 86wt% stearic acid, 2wt% graphite powder, 0.6wt% carbon nanosphere particles, 0.4wt% graphene, 6wt% aluminum hydroxide powder , 5wt% content of calcium magnesium carbonate powder.

[0042] The battery pack uses a high heat dissipation shell, the shell material, the content of polycarbonate 88wt%, the content of 1wt% carbon spheres, 0.5wt% graphene, 1.5wt% graphite, 5wt% alumina, 4wt% calcium magnesium silicon Salt composition, the outer casing adopts insulation resistance>10 10 Ω, thermal conductivity of 0.9 (W / K · M) characteristics of materials.

[0043] The implementation method of the battery structure with high stability and heat dissipation composite function o...

Embodiment 2

[0045] Composite phase change materials are used to meet the needs of batteries, and the temperature of the phase change point is 75°C, and the insulation resistance is >10 10 Ω, thermal conductivity 0.8(W / K·M), latent heat value up to 110(J / g).

[0046] In this composite phase change material, the content is 47wt% stearic acid, 37wt% paraffin, 3wt% graphite powder, 1.5wt% carbon nanosphere particles, 0.5wt% graphene, 2wt% hollow glass spheres , 4wt% content of inorganic phosphorus compound powder, 5wt% content of nano layered silicate powder.

[0047] The battery pack uses a high heat dissipation shell, the shell material, the content of polycarbonate 85wt%, the content of 1wt% carbon spheres, 0.5wt% graphene, 2.5wt% graphite, 6wt% alumina, 5wt% calcium magnesium silicon Salt composition, the outer casing adopts insulation resistance>10 10 Ω, thermal conductivity of 1.0 (W / K·M) characteristic materials.

[0048] For the battery with high stability and heat dissipation, a g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Insulation resistance | aaaaa | aaaaa |

| Latent heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com