High-strength flame-retardant black rock wool and preparation method thereof

A black rock wool, high-strength technology, applied in the field of high-strength flame-retardant black rock wool and its preparation, can solve the problems of poor freeze-thaw resistance, less water absorption, low toughness, etc., and achieves convenient operation, improved tensile strength, mechanical The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

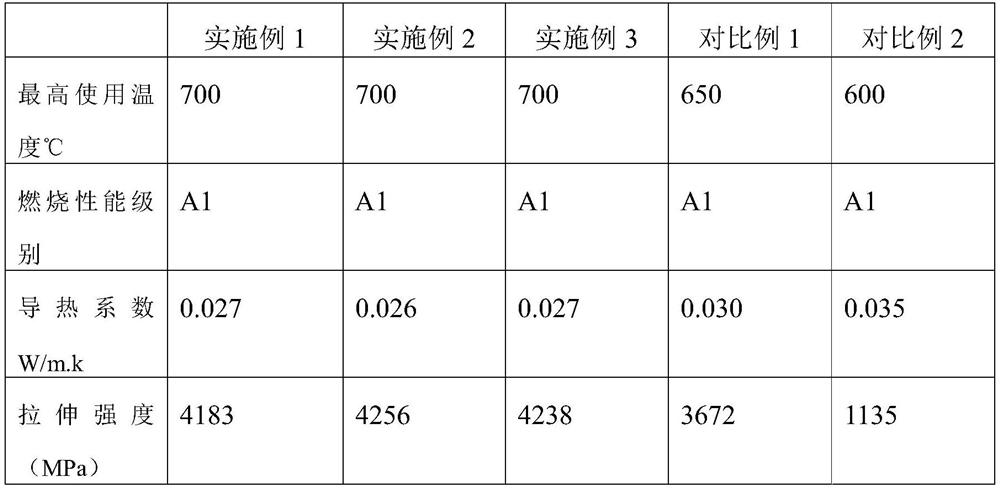

Examples

Embodiment 1

[0024] Concrete raw material is weighed according to following table 1, and step preparation steps are as follows:

[0025] (1) Pulverize and mix basalt, iron dolomite, slag and coke, and melt at 1450°C to obtain a melt;

[0026] (2) The molten body obtained in step (1) is centrifugally thrown into fibrous black rock wool at 200m / min, and at the same time, the mass concentration of 5% phenolic resin is sprayed on the surface of the fibrous black rock wool, and the injection amount is the total weight of the molten body 10%, and then superimposed fibrous black rock wool to form a multi-layer folded felt;

[0027] (3) The felt of the multi-layer folded structure obtained in step (2) is pleated and pressed, and basic magnesium sulfate whiskers and graphene oxide are added to the felt after pleating, and sent to solidification after being pressurized by a press. Furnace curing, that is.

Embodiment 2

[0029] (1) Pulverize and mix basalt, iron dolomite, slag and coke, and melt at 1550°C to obtain a melt;

[0030] (2) The molten body obtained in step (1) is centrifugally thrown into fibrous black rock wool at 250m / min, and at the same time, the mass concentration of the fibrous black rock wool is sprayed on the surface of the phenolic resin with a mass concentration of 5%, and the injection amount is the total weight of the molten body 15%, and then superimposed fibrous black rock wool to form a multi-layer folded felt;

[0031] (3) The felt of the multi-layer folded structure obtained in step (2) is pleated and pressed, and basic magnesium sulfate whiskers and graphene oxide are added to the felt after pleating, and sent to solidification after being pressurized by a press. Furnace curing, that is.

Embodiment 3

[0033] (1) Pulverize and mix basalt, iron dolomite, slag and coke, and melt at 1500°C to obtain a melt;

[0034] (2) The molten body obtained in step (1) is centrifugally thrown into fibrous black rock wool at 250m / min, and at the same time, the mass concentration of the fibrous black rock wool is sprayed on the surface of the phenolic resin with a mass concentration of 5%, and the injection amount is the total weight of the molten body 15%, and then superimposed fibrous black rock wool to form a multi-layer folded felt;

[0035] (3) The felt of the multi-layer folded structure obtained in step (2) is pleated and pressed, and basic magnesium sulfate whiskers and graphene oxide are added to the felt after pleating, and sent to solidification after being pressurized by a press. Furnace curing, that is.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com