Precise control method of hole-forming line pattern of anchor cable on high and steep rock slope with fractures

A rocky slope and control method technology, applied in excavation, construction, infrastructure engineering, etc., can solve problems such as increased anchor cable stress, uncoordinated support, safety accidents, etc., to reduce construction difficulty, real-time Strong, the effect of preventing safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further described below with reference to specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples are not intended to limit the present invention.

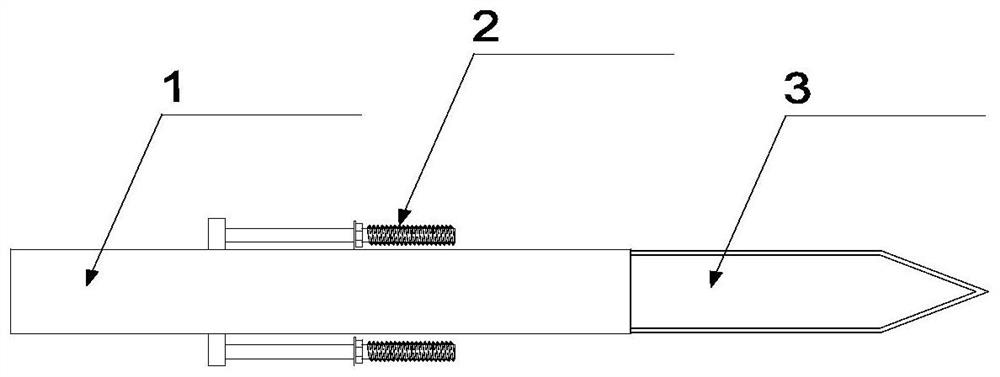

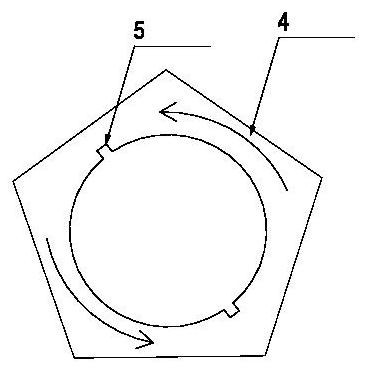

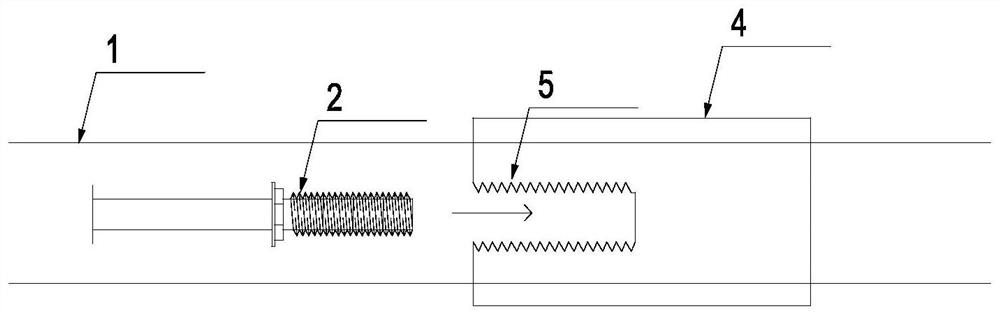

[0032] like Figures 1 to 6 As shown in the figure, a method for precise control of the pore-forming alignment of an anchor cable on a high and steep rock slope with developed fractures includes the following steps:

[0033] a. Position the anchor cable hole 6, and determine the inclination and diameter of the anchor cable hole 6. With the anchor cable hole 6 as the center, three reinforcement holes 7 tangent to the outer diameter of the anchor cable hole 6 are arranged. The connecting line of the center points of the reinforcement hole 7 is an equilateral triangle, and the diameter of the reinforcement hole 7 is determined;

[0034] b. Construction of reinforcement hole 7:

[0035] Fix the angle fixer on the slope, adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com