Production method of L80-9Cr martensitic stainless steel pipe

A martensitic stainless steel, production method technology, applied in the direction of metal extrusion cleaning equipment, metal extrusion, manufacturing tools, etc., can solve the unfavorable follow-up processing, cold Problems such as high difficulty in rolling processing, to achieve fine grain size, low cost, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the embodiments and accompanying drawings. The protection scope of the present invention is not limited to the embodiments, and any changes made by those skilled in the art within the scope defined by the claims also belong to the protection scope of the present invention.

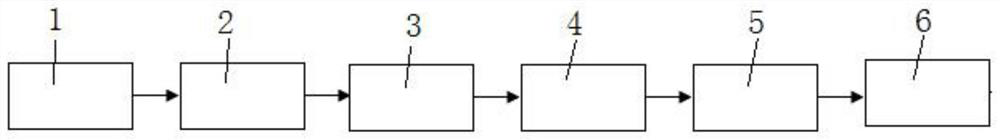

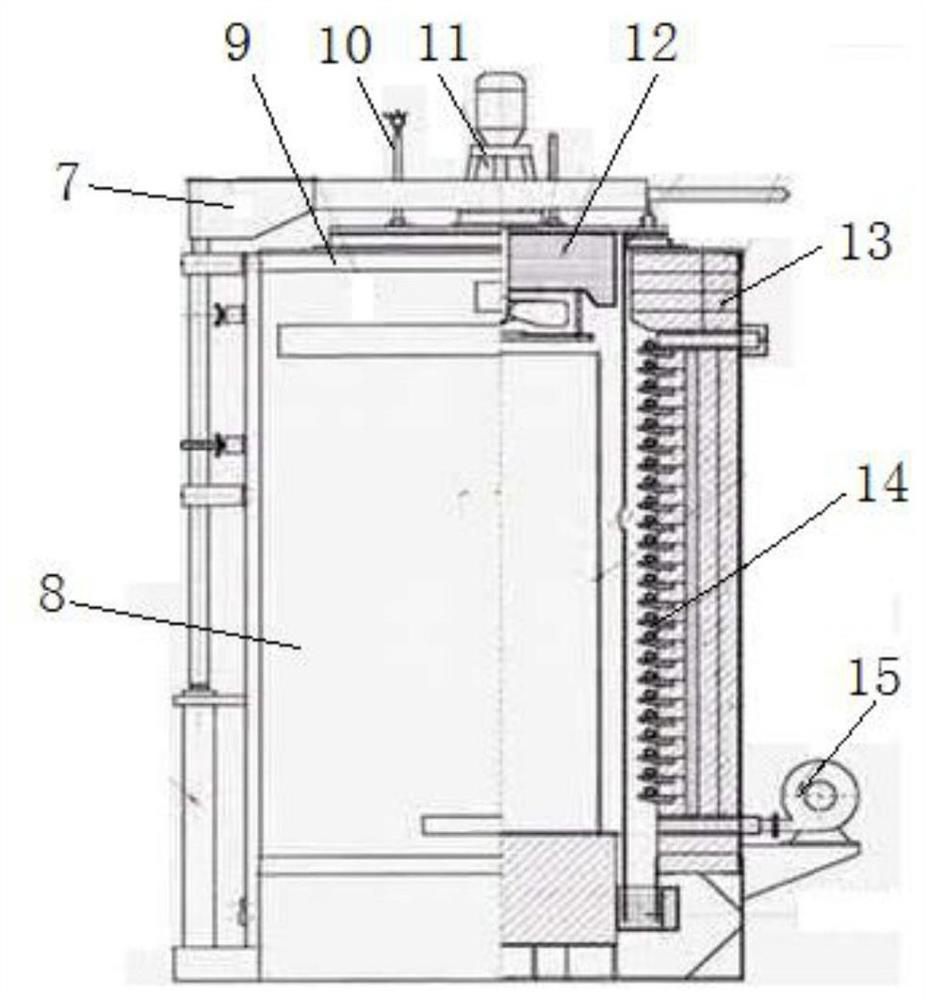

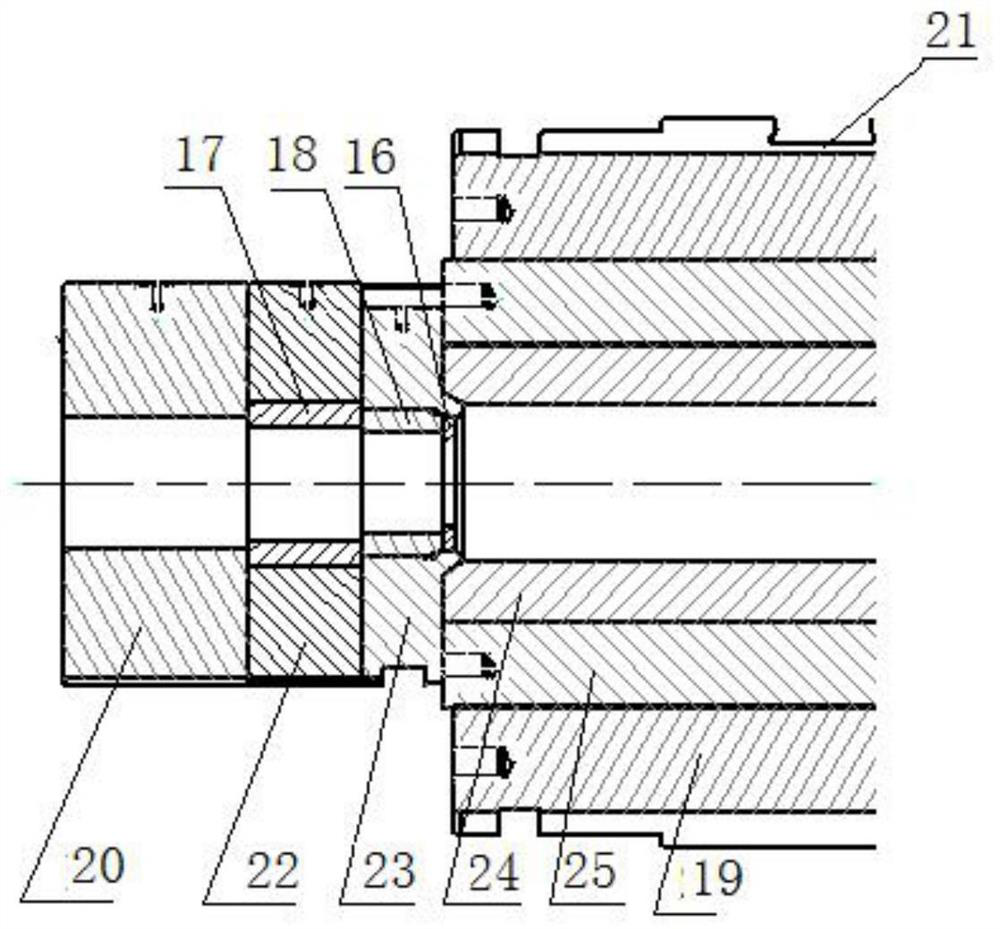

[0020] L80~9Cr martensitic stainless steel pipe production system such as figure 1 As shown, it includes centrifugal casting machine 1, annealing furnace 2, billet processing equipment 3, hole reaming machine 4, hot extrusion machine 5, heat treatment furnace 6 and quality inspection equipment. Centrifugal casting machine, annealing furnace, billet processing equipment, reaming machine, hot extrusion machine and heat treatment furnace are arranged in sequence, and the inspection equipment includes size specification inspection equipment and mechanical property inspection equipment. like figure 2 As shown, the annealing furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com