Electric vehicle charging completion battery heat preservation control system

A charging completion, electric vehicle technology, applied in electric vehicles, battery/fuel cell control devices, secondary batteries, etc., can solve the problems that affect the service life of the battery, the mileage of the car, the temperature drop of the battery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

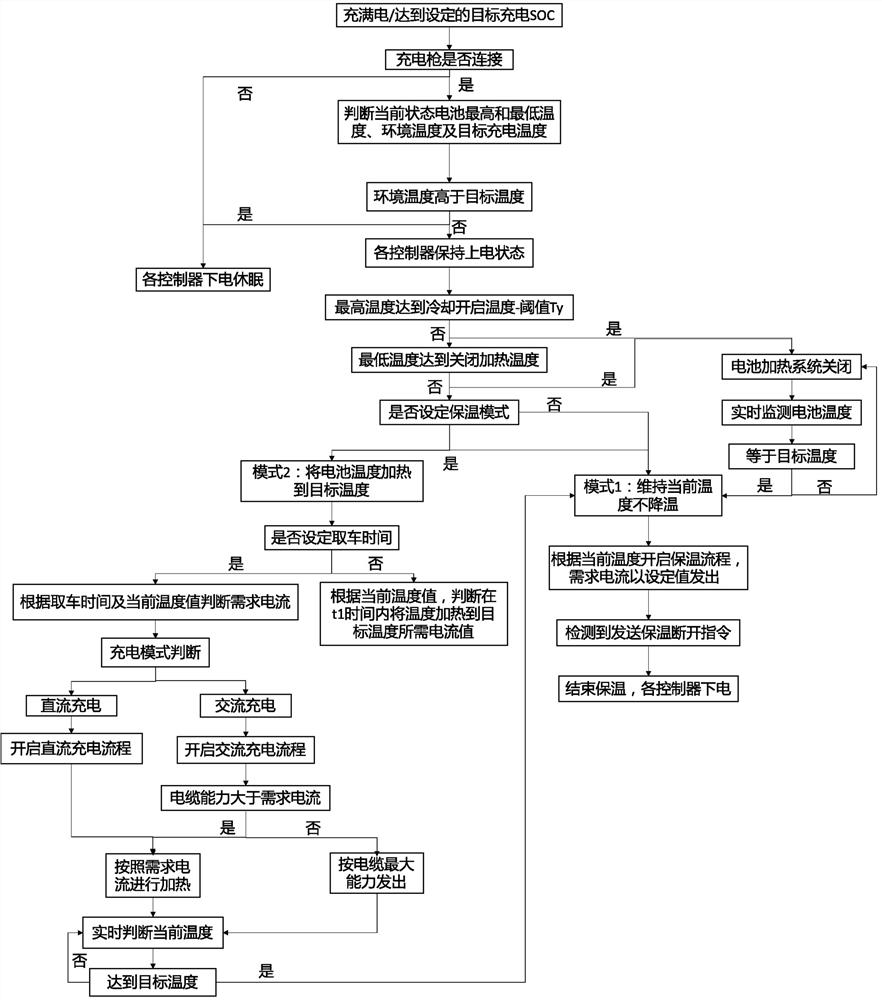

[0018] Attached below figure 1 The present invention will be described in detail.

[0019] The electric vehicle charging completes the battery insulation control system, including the charging gun, the vehicle system, the heating system, the battery management system and the battery cell; it works as follows:

[0020] Step 1) After the charging reaches the full charge state or reaches the designed target charging charge capacity SOC, the vehicle system controls the heating system and the battery management system to maintain the power-on state; if the charging gun is not connected, go to step 2); otherwise, go to step 3 );

[0021] Step 2) The vehicle system controls the heating system and the battery management system to power off and sleep; after that, go to step 5);

[0022] Step 3) The battery management system obtains and judges the maximum temperature T of the battery cell max , minimum temperature T min , ambient temperature T 0 and the set target temperature T t ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com