Environment-friendly dredging ship for improving water quality

A technology for purifying water quality and dredging ships, applied in water aeration, special-purpose ships, water treatment parameter control, etc., to achieve the effects of shortening aeration time, reducing treatment costs, restoring ecological functions and regulating functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

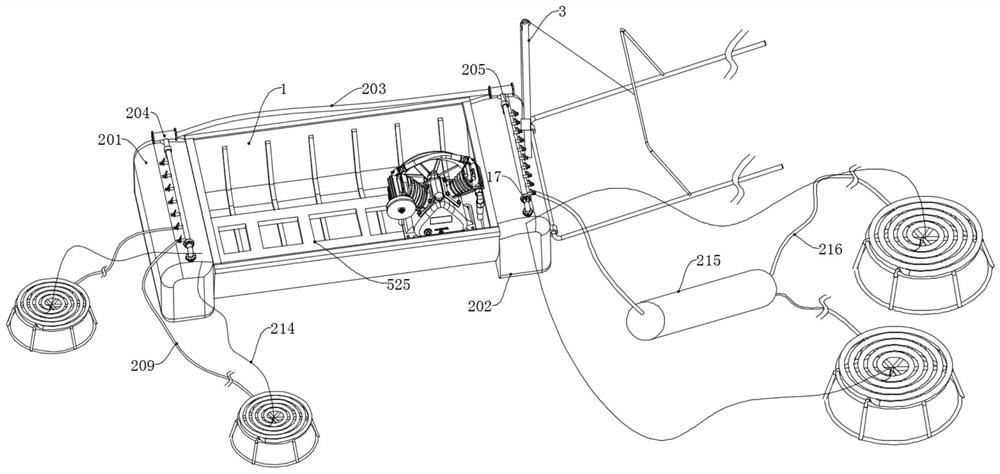

[0043] This embodiment discloses an environment-friendly dredging ship for purifying water, including a hull 1, a high-pressure aeration water purification system 2, an adjustable aeration system 3, a mud-water separation system 4, an aeration output system 5 and a power ship. The power boat is arranged at the tail end of the hull 1, and the power boat is connected to the hull 1 to drive the hull 1 to travel in waters;

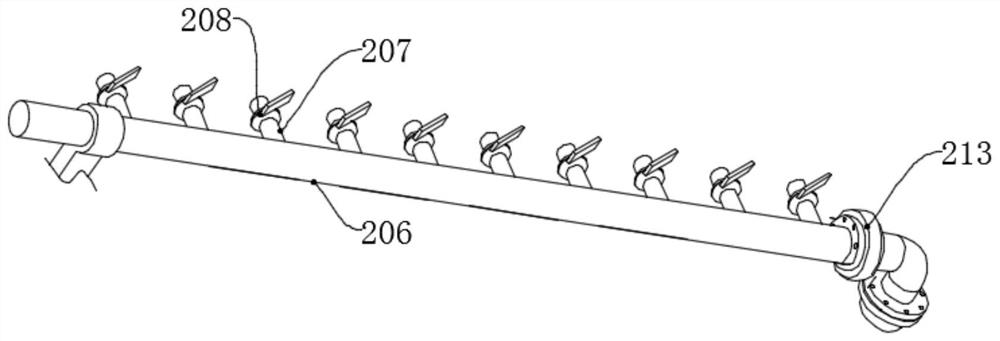

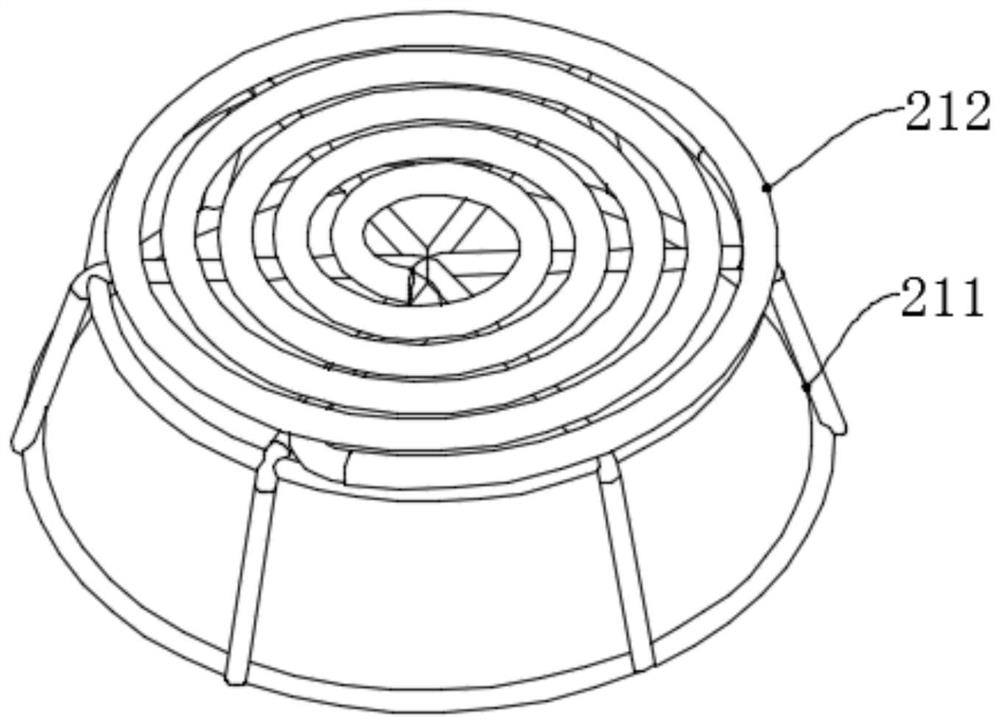

[0044] The high-pressure aeration water purification system 2 and the adjustable aeration system 3 are installed on the hull 1, the adjustable aeration system 3 is connected to the high-pressure aeration water purification system 2, the high-pressure aeration water purification system 2 and the adjustable aeration system The air system 3 is used to aerate the bottom of the water to achieve the purpose of purifying water;

[0045] The mud-water separation system 4 is installed in the hull 1, and the mud-water separation system 4 is used to mix and pump the mud-...

Embodiment 2

[0105] This embodiment is further optimized on the basis of Embodiment 1. In this embodiment, the bottom of the hull 1 is provided with a hydraulic shock absorbing and anti-collision structure 6, and the hydraulic shock absorbing and anti-collision structure 6 includes the bottom of the hull 1 and the side of the hull 1. The outer protective layer 601, and an interlayer 602 formed between the outer protective layer 601 and the hull 1, hydraulic oil is provided in the interlayer 602;

[0106] Through the outer protective layer 601 provided, an interlayer 602 is formed between the outer protective layer 601 and the hull 1, and hydraulic oil is injected into the interlayer 602 to form a hydraulic shock-absorbing anti-collision structure 6, which can effectively improve the hull 1. The shock absorption effect can effectively absorb the impact force brought by the power equipment on the hull 1 and the hull 1 during the movement; the bottom of the hull 1 forms a double-layer structur...

Embodiment 3

[0108] This embodiment is further optimized on the basis of Embodiment 2. In this embodiment, the outer protective layer 601 has multiple layers, and a first interlayer 602 is formed between adjacent outer protective layers 601. Filled with hydraulic oil.

[0109]In this way, a multi-layer buffer structure can be formed at the bottom of the hull 1 to further improve the effect of anti-seismic buffering, and at the same time, the formed multi-layer structure can also further protect the bottom of the hull 1 . It can reinforce the bottom of the hull 11 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com