Recovery and utilization of neutralized water in plasticizer DOTP production process

A production process and plasticizer technology, applied in water pollutants, filtration treatment, water/sewage treatment, etc., can solve the problems of complex process and difficult treatment, and achieve simple recovery process, high safety, and good separation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

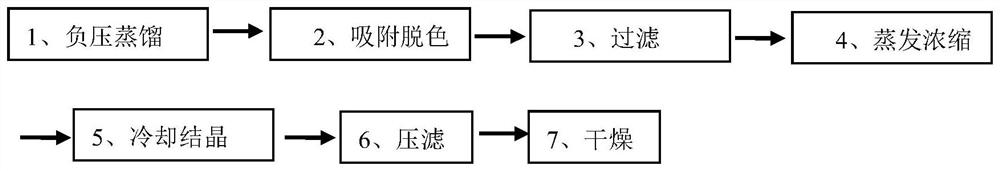

Method used

Image

Examples

Embodiment 1

[0022] Put 2000kg of neutralized water into a stirred and pressure-resistant 3000L stainless steel still, start the stirring, turn on the steam in the jacket of the still, and slowly heat up to 78°C. Then turn on the vacuum unit, carry out distillation under the condition of vacuum degree of -0.97MPa, and collect fractions to obtain 118kg of material isooctyl alcohol.

[0023] After the distillation is completed, add 6 kg of inorganic filter agent into the distillation kettle, stir for 30 minutes, and then cool the material to 38°C.

[0024] Transfer the material in the cooled distillation pot to a filter for filtration, and filter out the inorganic filter to obtain a colorless and transparent filtrate.

[0025] Transfer the filtrate after decolorization and filtration into a thin-film evaporator, turn on the steam to heat to 95°C, and turn on the vacuum unit at the same time, and evaporate and concentrate the filtrate under the vacuum degree of -0.85MPa. When tiny crystals ap...

Embodiment 2

[0030] Put 2200kg of neutralized water into a 3000L stainless steel still with stirring and pressure resistance, start the stirring, turn on the steam in the jacket of the still, and slowly heat up to 80°C. Then turn on the vacuum unit, carry out distillation under the state of vacuum degree of -0.96MPa, collect fractions to obtain 129kg of material iso-octanol.

[0031] After the distillation is completed, add 6.5kg of inorganic filter agent into the distillation kettle, stir for 30min, and then cool the material to 36°C.

[0032] Transfer the material in the cooled distillation pot to a filter for filtration, and filter out the inorganic filter to obtain a colorless and transparent filtrate.

[0033] Transfer the filtrate after decolorization and filtration into a thin-film evaporator, turn on the steam to heat to 96°C, and turn on the vacuum unit at the same time, and evaporate and concentrate the filtrate under the state of vacuum degree of -0.86MPa. When tiny crystals app...

Embodiment 3

[0038] Put 2500kg of neutralized water into a stirred and pressure-resistant 3000L stainless steel still, start the stirring, turn on the steam in the jacket of the still, and slowly heat up to 81°C. Then turn on the vacuum unit, carry out distillation under the state of vacuum degree of -0.98MPa, collect fractions to obtain 142kg of material iso-octanol.

[0039] After the distillation is completed, add 7kg of inorganic filter agent into the distillation kettle, stir for 30min, and then cool the material to 38°C.

[0040] Transfer the material in the cooled distillation pot to a filter for filtration, and filter out the inorganic filter to obtain a colorless and transparent filtrate.

[0041] Transfer the filtrate after decolorization and filtration into a thin-film evaporator, turn on the steam and heat it to 97°C, and at the same time turn on the vacuum unit, and evaporate and concentrate the filtrate at a vacuum degree of -0.84MPa. When tiny crystals appear on the sight gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com