Blast furnace hearth masonry structure for eliminating blast furnace air gap

A technology of masonry structure and blast furnace, which is applied in blast furnace, blast furnace details, blast furnace parts and other directions, can solve the problems of destroying the integrity of the heat transfer system of the hearth, reducing the service life of the blast furnace, and insufficient consolidation strength, and achieves favorable results. Effects of blast furnace longevity, elimination of blast furnace hearth air gaps, and reduction of abnormal erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

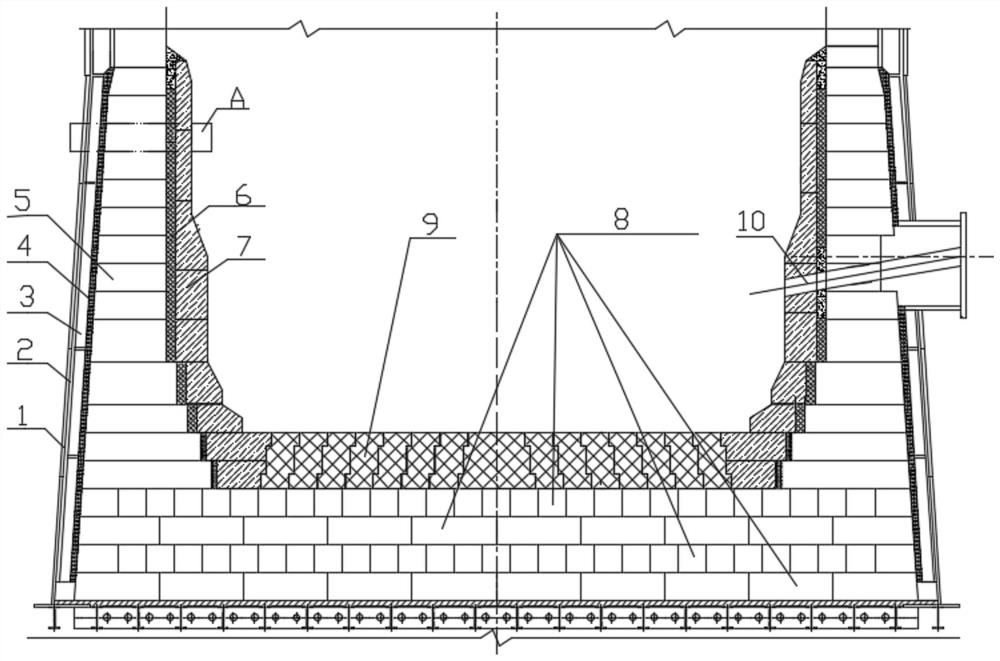

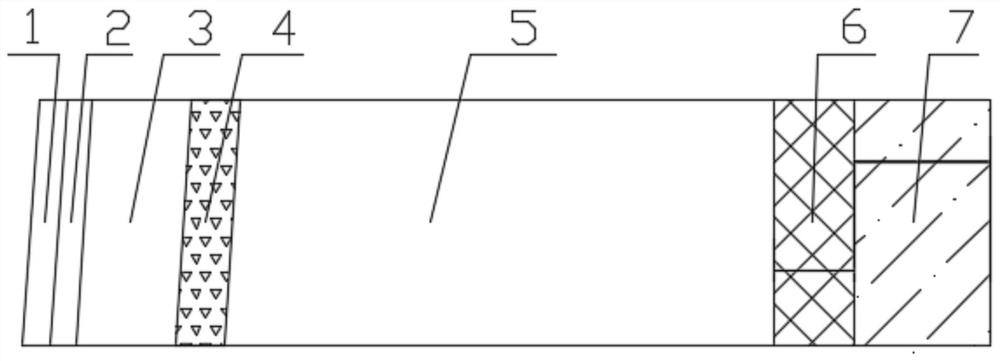

[0027] From the outside to the inside of the hearth of the traditional large carbon brick blast furnace, the side walls are the furnace shell 1, the packing layer 2, the cooler 3, the pounding layer between the carbon brick and the cooler, the large carbon brick 5, the ceramic cup and the charcoal Ramping layer between bricks and ceramic cup7. The function of the pounding layer between the carbon brick and the cooler and between the ceramic cup and the carbon brick is to absorb expansion and fill the gap.

[0028] like Figure 1~2 As shown, the present invention replaces the ramming layer between the carbon brick and the cooler or / and the ramming layer between the ceramic cup and the carbon brick with a high thermal conductivity castable. The furnace hearth side wall of the present invention is successively from the outside to inside the furnace shell 1, the packing layer 2, the cooler 3, the first pouring material layer 4 between the carbon brick and the cooler, the large ca...

Embodiment 2

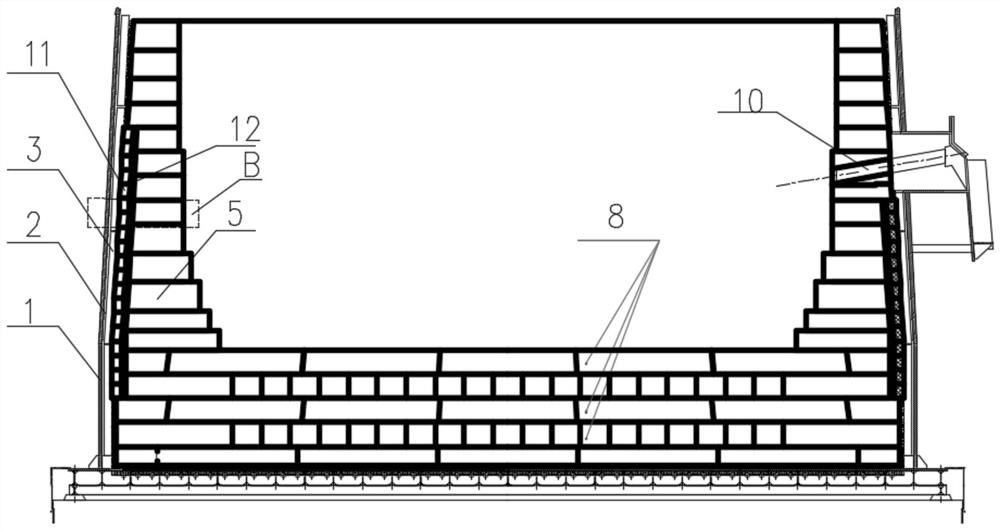

[0031] like Figure 3-4 As shown, the side wall of the traditional small carbon brick + large carbon brick blast furnace hearth is furnace shell 1, packing layer 2, cooler 3, small carbon brick 11, small carbon brick and large carbon brick from outside to inside. Ramping layer between bricks, large charcoal bricks 5. The role of the pounding layer between the small carbon brick and the large carbon brick is to absorb expansion and fill the gap.

[0032]The invention replaces the pounding material layer between the small carbon bricks and the large carbon bricks with high thermal conductivity pouring material. The furnace hearth side wall of the present invention is successively furnace shell 1, packing layer 2, cooler 3, small carbon brick 11, the third pouring material layer 12 between the small carbon brick and the large carbon brick, from outside to inside. Large charcoal bricks 5.

[0033] Due to the limitation of the size of the ramming equipment, etc., the thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com