A blast furnace tuyere protection device

A protection device and tuyere technology, applied in the direction of the tuyere, can solve the problems of poor thermal conductivity at the gap of the tuyere, uneven packing density, waste of water loss of the packing, etc., and achieves the effect of saving material consumption, reducing damage, and reducing the probability of damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

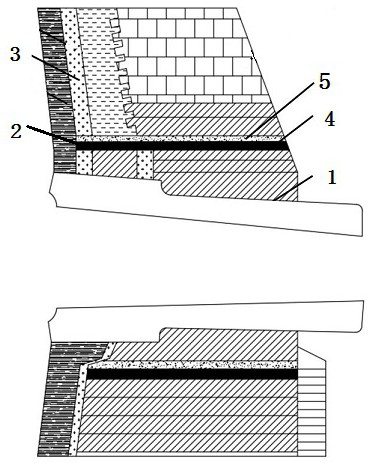

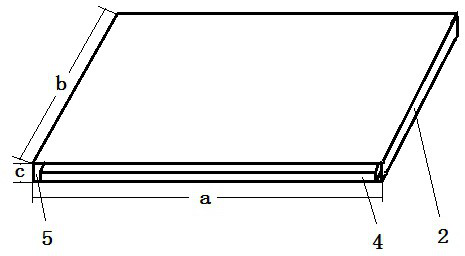

[0019] Such as figure 1 and figure 2 As shown, a blast furnace tuyere protection device, the blast furnace tuyere includes a tuyere composite brick 1 , a tuyere gap 2 and a tuyere stave 3 . The tuyere gap 2 is a cavity structure, which is arranged between the tuyere combined brick 1 and the tuyere cooling wall 3, the length of the tuyere gap 2 is a=1000 mm, the depth is b=140 mm, and the height is c=25mm. The protection device is arranged in the gap 2 of the tuyere, and the protection device includes a heat conduction device 4 and a filling device 5 . The length of the heat conducting device 4 is 995 mm, the depth is 137 mm, and the height is 10 mm. The heat conducting device 4 is a copper sheet with a purity of 99.99%, and the tuyere cooling stave 3 is a cast iron cooling stave, that is, the thermal conductivity of the heat conducting device 4 is greater than that of the tuyere cooling stave 3 . The filling device 5 covers the heat conduction device 4 and adheres to the ...

Embodiment 2

[0023] Such as figure 1 and figure 2 As shown, a blast furnace tuyere protection device, the blast furnace tuyere includes a tuyere composite brick 1 , a tuyere gap 2 and a tuyere stave 3 . The tuyere gap 2 is a cavity structure, which is arranged between the tuyere combined brick 1 and the tuyere cooling wall 3, the length of the tuyere gap 2 is a=1000 mm, the depth is b=150 mm, and the height is c=30mm. The protection device is arranged in the gap 2 of the tuyere, and the protection device includes a heat conduction device 4 and a filling device 5 . The length of the heat conducting device 4 is 1000 mm, the depth is 150 mm, and the height is 15 mm. The heat conducting device 4 is a copper sheet with a purity of 99.99%, and the tuyere cooling stave 3 is a copper cooling stave, that is, the thermal conductivity of the heat conducting device 4 is equal to that of the tuyere cooling stave 3 . The filling device 5 covers the heat conduction device 4 and adheres to the cavity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com