Full-automatic continuous coal distribution device

A fully automatic coal transportation technology, applied in the direction of supply configuration, combustion method, block/powder supply/distribution, etc., can solve the problems of high harmful gas discharge, low boiler combustion efficiency, large energy waste, etc., and achieve improvement Combustion efficiency, prolonging service life, and reducing oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

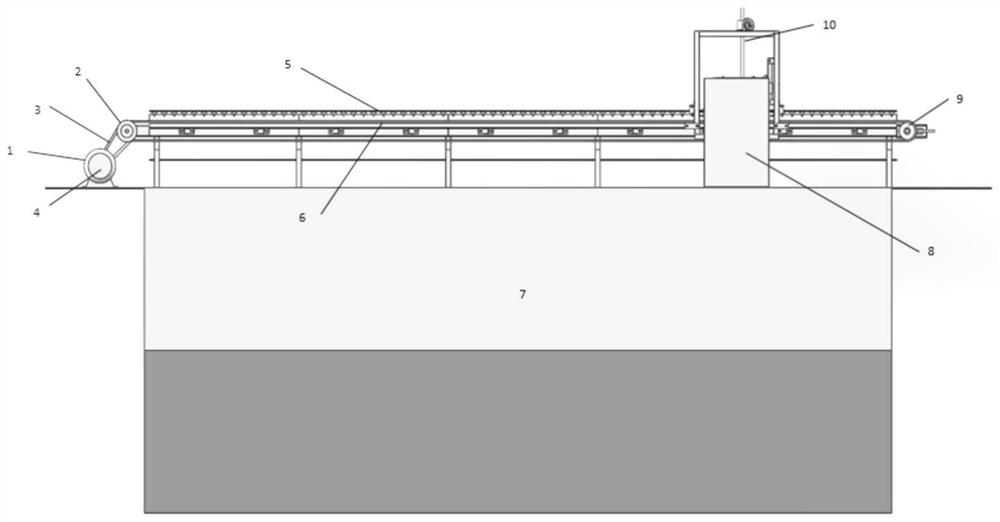

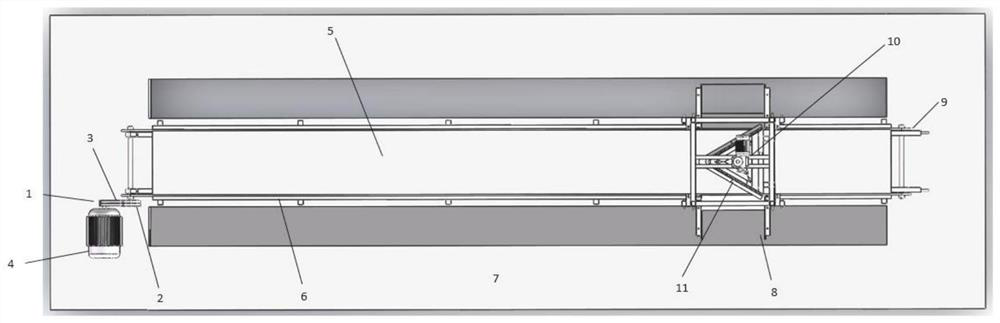

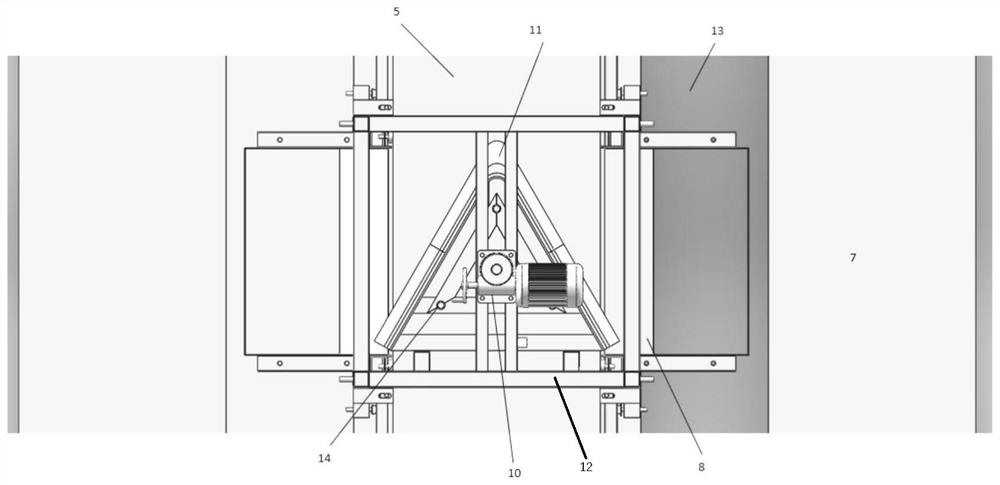

[0031] Such as Figure 1-6 As shown, the technical solution adopted in the present invention is a fully automatic continuous coal distributing device, which includes a driving pulley 1, a driven pulley 2, a belt 3, a reducer 4, a coal conveyor belt 5, a chain 6, a coal Storehouse 7, coal hopper 8, driven sprocket 9, coal plow lifting platform 10, coal plow 11, coal plow trolley 12, coal passage 13. The output shaft of the reducer 4 is coaxially connected with the driving pulley 1; the driving pulley 1 and the driven pulley 2 are connected by a belt 3; the coal conveyor belt 5 is installed in the middle of the top of the coal bunker 7, and the driven pulley 2. Coaxial with the driving sprocket (not shown in the figure), the driven sprocket 9 and the driving sprocket are symmetrically arranged at both ends of the coal conveyor belt 5, and the driving spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com