Flat plate type loop heat pipe suitable for two vertical heat sources

A loop heat pipe, flat plate technology, used in indirect heat exchangers, lighting and heating equipment, etc., can solve the problem of inability to dissipate heat from two vertical heat sources, and solve the problem that the area and shape of the outlet do not match the vertical heating surface, avoid The effect of partial drying and small distance between micro-columns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

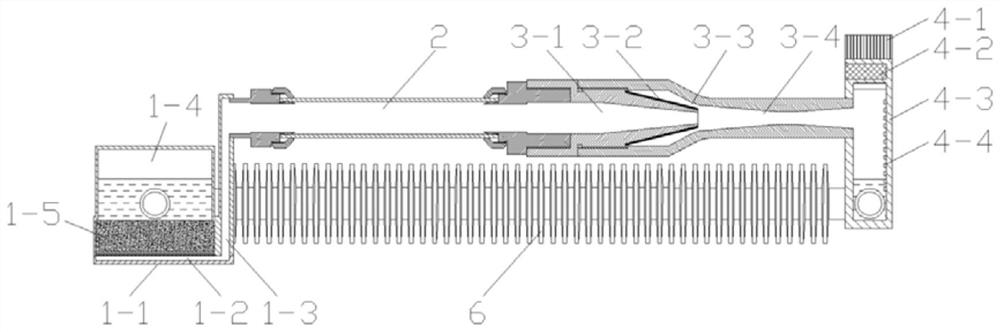

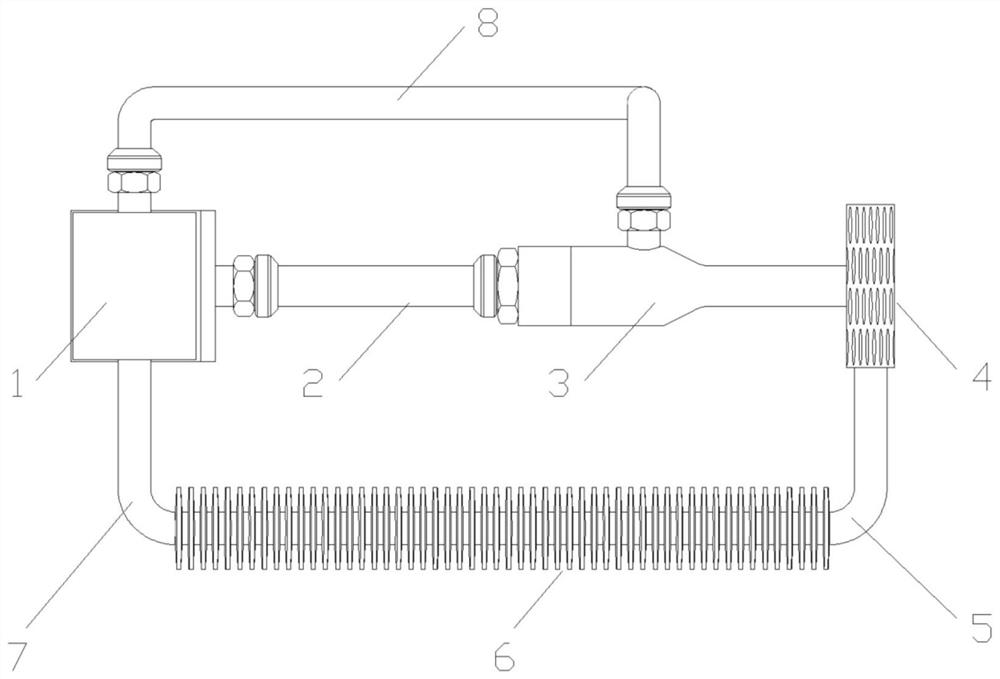

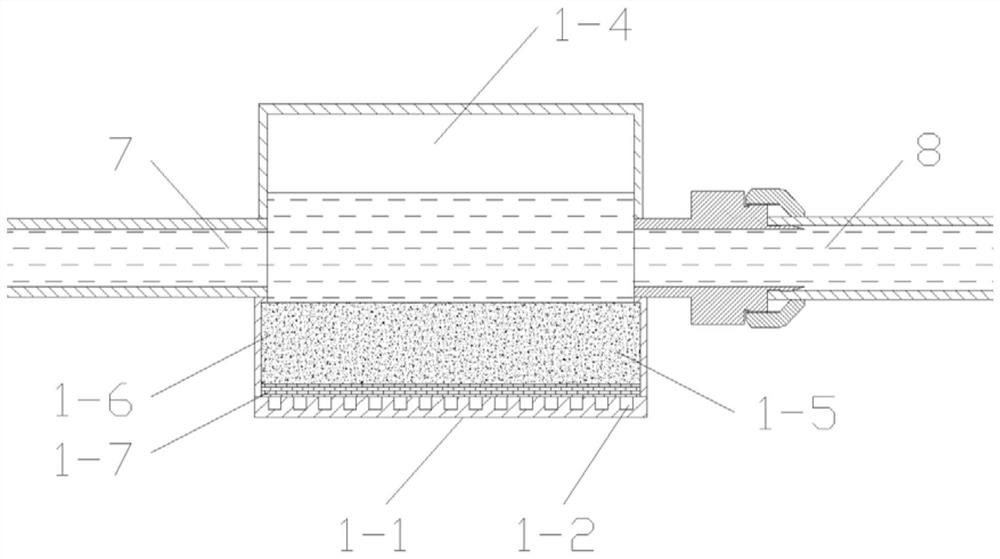

[0030] see figure 1 and figure 2 , a flat-plate loop heat pipe suitable for two vertical heat sources, mainly including an evaporator 1, a jet pump 3, a jet heat exchange chamber 4 and a cooler 6. The bottom surface of the evaporator is a horizontal heat exchange surface 1-1, which is attached to the horizontal heat source, and the side of the jet heat exchange chamber 4 is a vertical heat exchange surface 4-3, which is attached to the vertical heat source. Cooler 5 adopts finned tube type air-cooled cooler. Wherein, the liquid outlet of the evaporator 1 is connected to the jet pump 3 through the third liquid pipeline 8, the gas outlet of the evaporator 1 is connected to the jet pump 3 through the steam pipeline 2, the jet pump 3 is connected to the jet heat exchange chamber 4, and the jet flow The heat exchange chamber 4 is connected to the liquid inlet of the eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com