An automatic batch thermal stripping device for optical fiber coating

A coating and optical fiber technology, which is applied in the field of automatic batch thermal stripping devices for optical fiber coatings in batches, can solve the problems of reducing thermal stripping speed, low safety, etc., avoiding waste of manpower, material resources and time, and simple operation method. , to ensure the effect of clamping consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

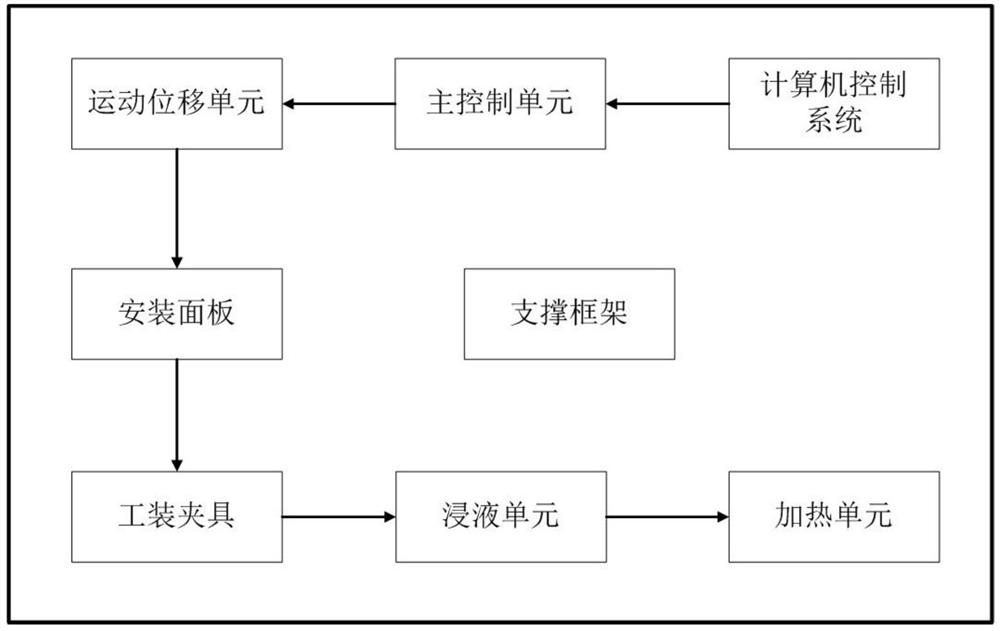

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

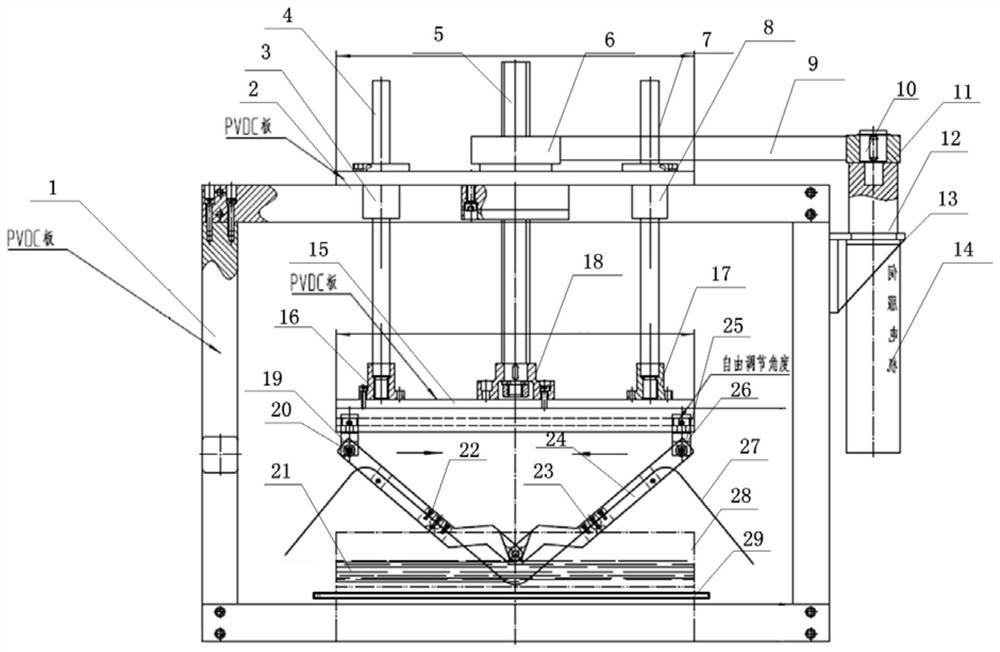

[0037] like figure 2 As shown, this embodiment discloses a batch thermal stripping device for optical fiber coating, including a support frame 1, an upper mounting plate 2, a connecting rod sleeve A3, a connecting rod A4, a lead screw 5, a gear A6, a connecting rod B7, a connecting rod Rod sleeve B8, belt 9, gear B10, coupling 11, reducer 12, motor mounting bracket 13, servo motor 14, lower mounting plate 15, connecting rod mounting seat A16, connecting rod mounting seat B17, screw mounting seat 18. Pin shaft A19, rotation pin A20, acid solution 21, rubber sheet A22, rubber sheet B23, splint frame 24, pin shaft B25, rotation pin B26, optical fiber 27, container 28, heating device 29.

[0038] The main function of the support frame 1 is to support the entire control device.

[0039] The main functions of the upper mounting plate 2 and the lower mounting plate 15 are to install and fix the screw 5, the connecting rod A4, the connecting rod B7, the clamping plate frame 24, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com