Quality prediction system and quality prediction method

A quality prediction and quality technology, applied in the manufacturing field, can solve the problems of no correlation, disconnected traceability, difficult to achieve correlation, etc., to achieve the effect of easy discovery, overcoming defects that are easy to miss, and small in size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

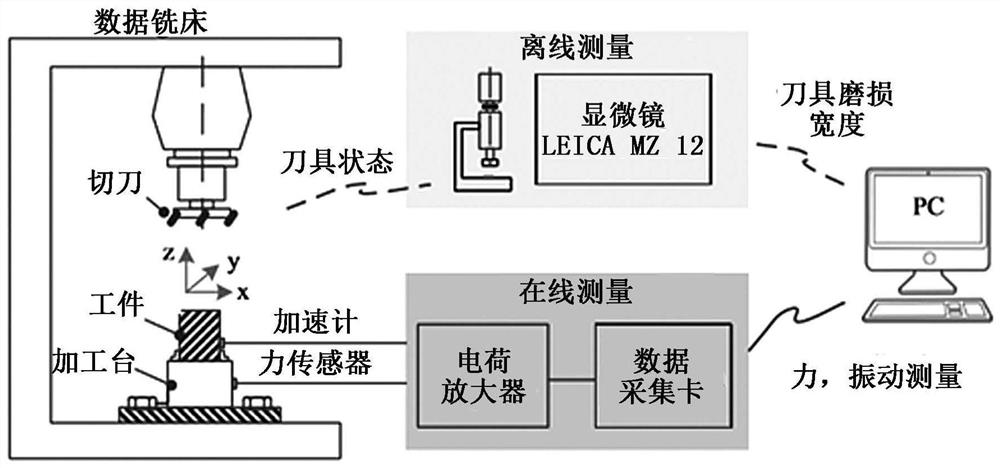

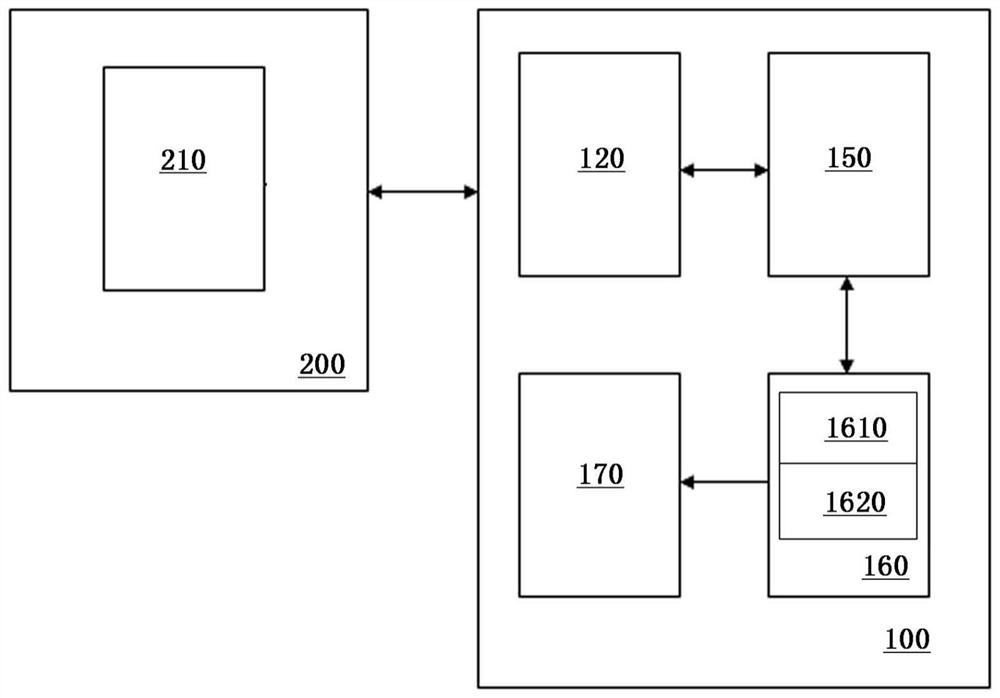

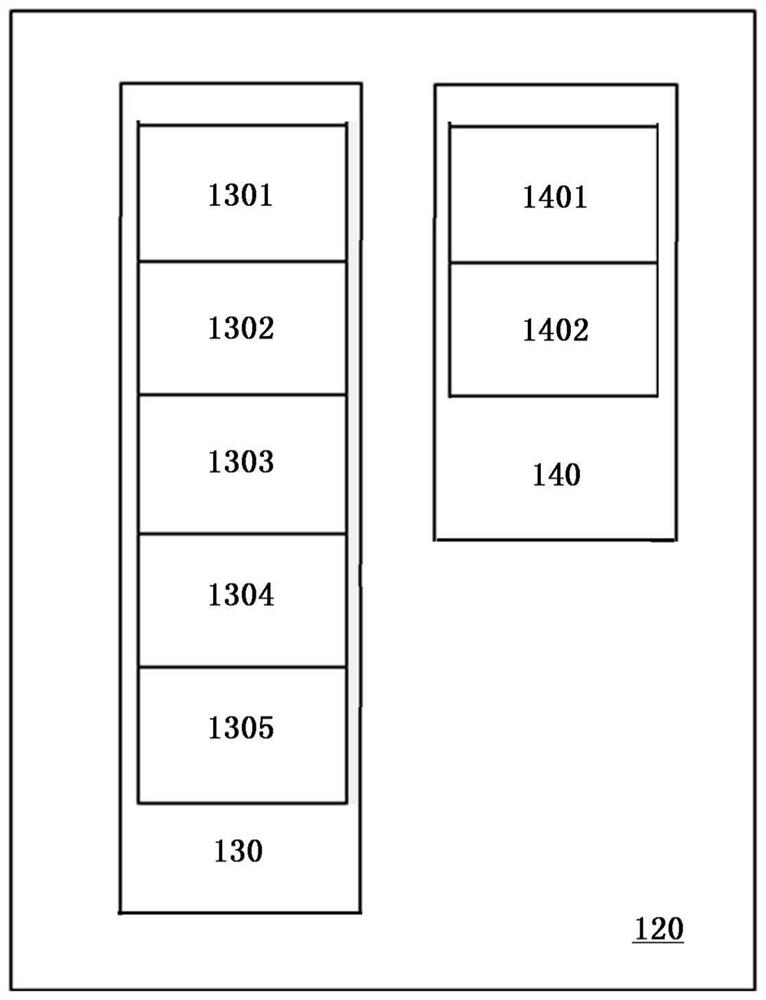

[0060] figure 1 The product quality detection method in the prior art is shown. figure 1 It shows a product quality inspection method in the prior art under the scene of computer numerical control (CNC) machine tool processing parts. although figure 1 The detailed scene is shown in , but this article will focus on the description of the two quality detection methods in the prior art, and the description of other parts will be omitted. Such as figure 1 As shown, when the parts are processed, the parts to be processed are fixed on the machine table. The control part of the CNC machine tool controls the CNC machine tool to cut the blank according to the control data and operation data (for example, including G code and M code) input by the operator, so as to manufacture the target part. Usually, after the manufacturing is completed, the quality of the parts needs to be checked to determine whether the quality of the parts meets the predetermined requirements. according to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com