Method for testing and screening bad IV curve of Schottky chip

A screening method and chip technology, applied in the direction of single semiconductor device testing, measuring electricity, measuring devices, etc., can solve the problems of increasing customer production costs, not outflowing, and not being able to fully achieve abnormalities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

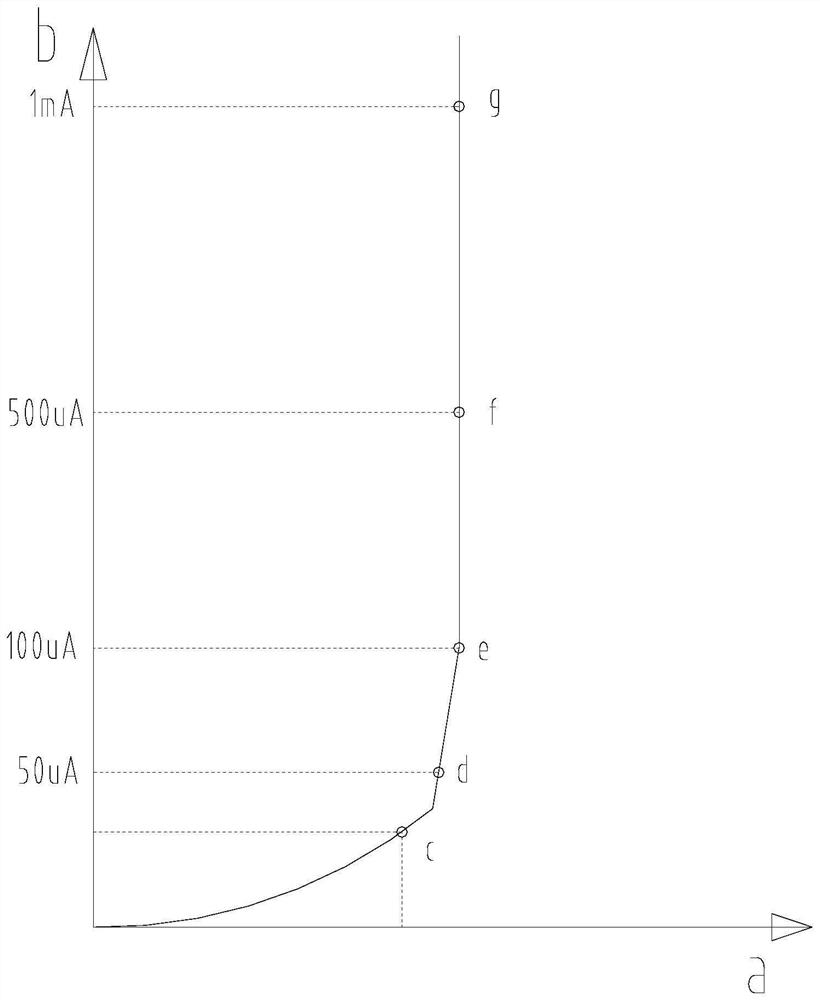

[0054] The present invention as Figure 1-2 Shown, a kind of test screening method of Schottky chip IV bad curve, comprises the following steps:

[0055] 1) Place the Schottky chip to be tested on the test plate of the probe station, and automatically adjust the level of the Schottky chip through the probe station (easy to locate the first Schottky chip);

[0056] 2) Locate the first die on the Schottky chip through the preset image of the probe station (the Schottky chip has several prepared dies);

[0057] 3) The test disc moves upwards to contact with the test probes on the probe station;

[0058] 4) Through the 1mA current given by the test box on the probe station, judge whether the test probe (tungsten needle) is in contact with the first die;

[0059] 4.1) If the probe station shows that the test probe is in good contact with the first die;

[0060] 4.11) The test box gives a reverse current of 50uA, test the reverse voltage, and the test box records its reverse volt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com