Process for producing a membrane protein

A membrane protein, centrifugation technology, which can be used in the preparation methods of peptides, chemical instruments and methods, animal/human proteins, etc., and can solve problems such as troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

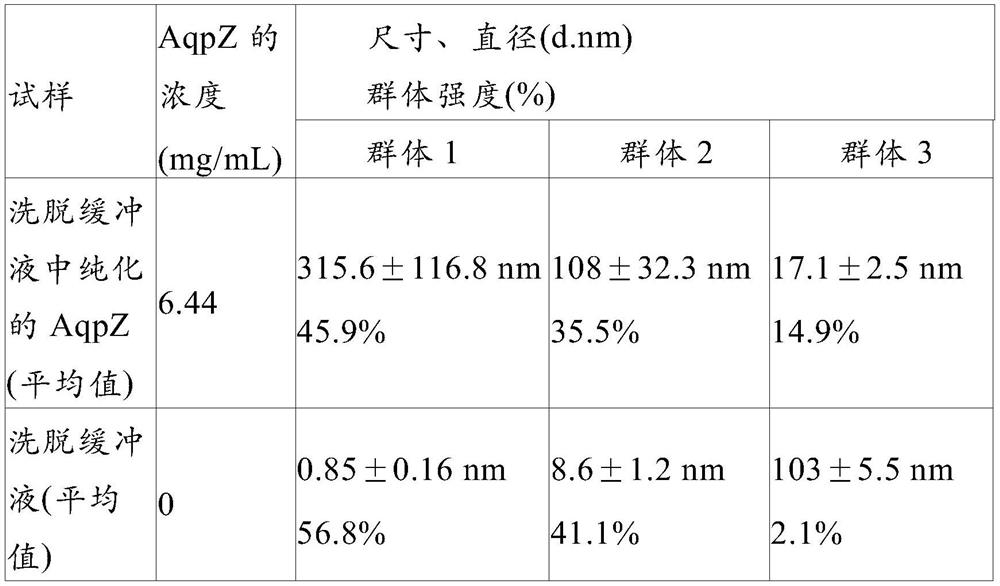

Image

Examples

Embodiment 1

[0047] An E. coli BL21 strain containing a vector producing aquaporin linked to a C-terminal His-tag was prepared. The His-tag contains ten consecutive histidine molecules that are attached to the primary sequence of the aquaporin membrane protein.

[0048] E. coli strains were cultivated in standard medium to obtain 150 L of total fermentation broth, and E. coli cells were harvested by filtering the fermentation broth with a microfiltration membrane with a pore size of 0.05 μm. The filtrate containing E. coli cells was reduced to about 50 L and then centrifuged at 5300 g for 20 minutes. Therefore, E. coli cells were concentrated by microfiltration, and the remaining medium was subsequently removed as a supernatant by centrifugation.

[0049] The pellet obtained by centrifugation was collected, and 0.9% NaCl was added at a volume of 1:1 to wash the cells and dissolve contaminating salts. Subsequently, the wash solution was removed in a centrifuge run at 5300 g for 20 minutes...

Embodiment 2

[0054] E. coli strain BL21 was prepared containing a vector producing aquaporin linked to a C-terminal His-tag. The His-tag contains ten consecutive histidine molecules that are attached to the primary sequence of the aquaporin membrane protein.

[0055] Escherichia coli strains were cultivated in standard medium to obtain 250 L of total fermentation broth, and the fermentation broth was filtered through a PES flat membrane with a pore size of 0.05 μm to harvest Escherichia coli cells. The filtrate containing E. coli cells was reduced to approximately 50 L and then centrifuged at 5300 g for 20 minutes in a Sorvall 16L centrifuge. Therefore, E. coli cells were concentrated by microfiltration, and the remaining medium was subsequently removed as a supernatant by centrifugation. The pellet can be stored frozen at -20°C or used directly in the next step.

[0056] The pellet containing E. coli cells was resuspended in about 50 L of buffer (aqueous solution of the protease inhibit...

Embodiment 3

[0061] E. coli strain BL21 was prepared containing a vector producing aquaporin linked to a C-terminal His-tag. The His-tag contains ten consecutive histidine molecules that are attached to the primary sequence of the aquaporin membrane protein.

[0062] E. coli strains were grown in standard medium to obtain 250 L of total fermentation broth, and the OD600 value of the fermentation batch at harvest was 13, induced for 42.5 hours. The material was homogenized twice at 100 MPa in a Stansted nm-GEN7575 homogenizer. Remove 10 mL from the lysed material and add to a 15 mL Falcon tube.

[0063] Then it was centrifuged at 5300 g for 1 hour, and the precipitated particles were separated from the supernatant. The pellet was then resuspended in 10 mL of 0.9% NaCl. The BCA assay was used to determine the concentration (mg / mL total protein) of the resuspended pellet and the separated supernatant after the first spin.

[0064] Finally the resuspended pellet and isolated supernatant we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com