Management method based on steelmaking continuous casting production management optimization

A technology of production management and management method, applied in the field of continuous casting and steelmaking, can solve the problems of inability to clean the surface of the steel, uneven heating of some parts of the steel, affecting the production quality of the steel, etc., to achieve easy recycling, good thermal conductivity, The effect of easy maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

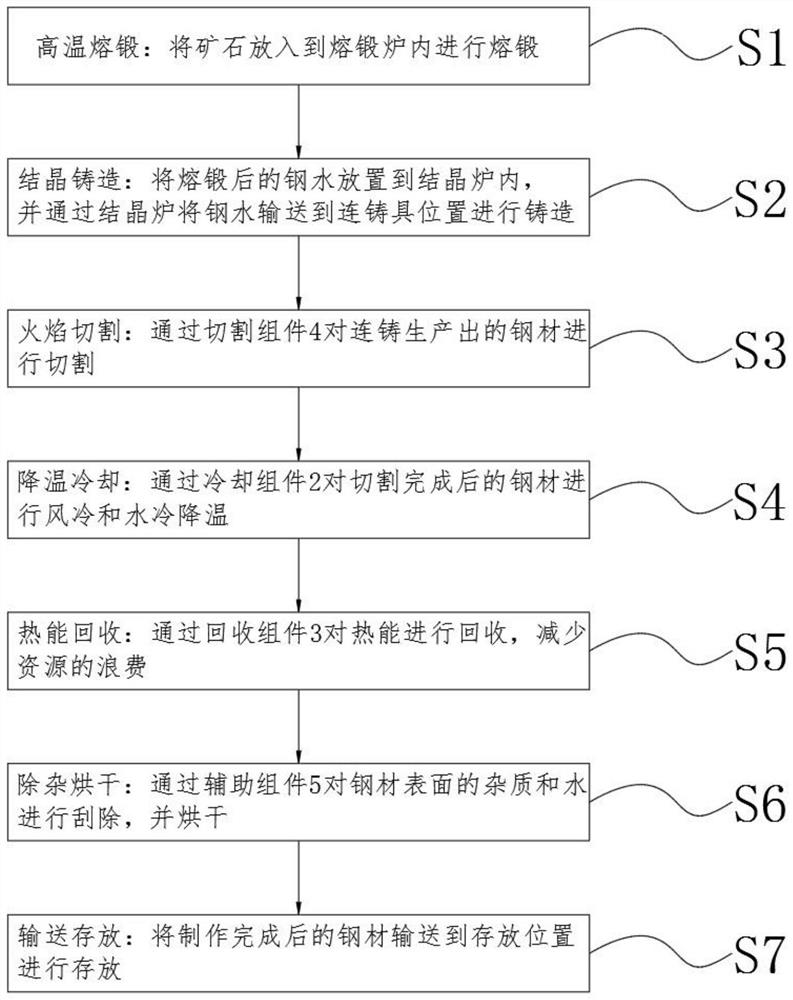

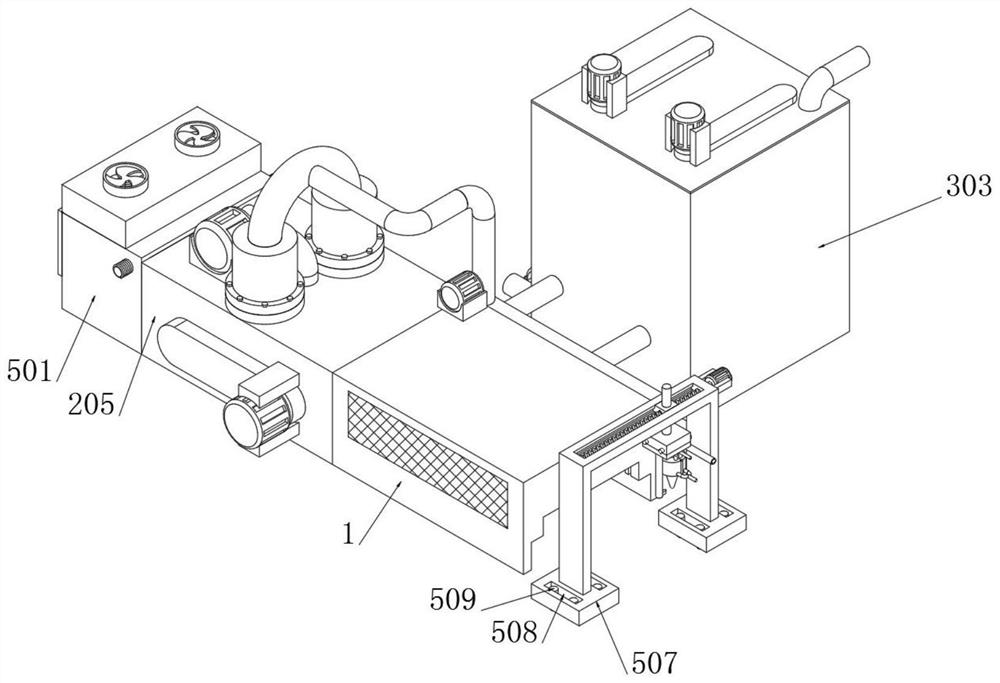

[0061] Example: such as Figure 1-13 As shown, the present invention provides a technical solution, a management method based on steelmaking and continuous casting production management optimization, comprising the following steps:

[0062] S1: High-temperature melting and forging: put the ore into the melting and forging furnace for melting and forging;

[0063] S2: Crystallization casting: Put the molten steel after melting and forging into the crystallization furnace, and transport the molten steel to the position of the continuous casting tool through the crystallization furnace for casting;

[0064] S3: flame cutting: cutting the steel produced by continuous casting through the cutting component 4;

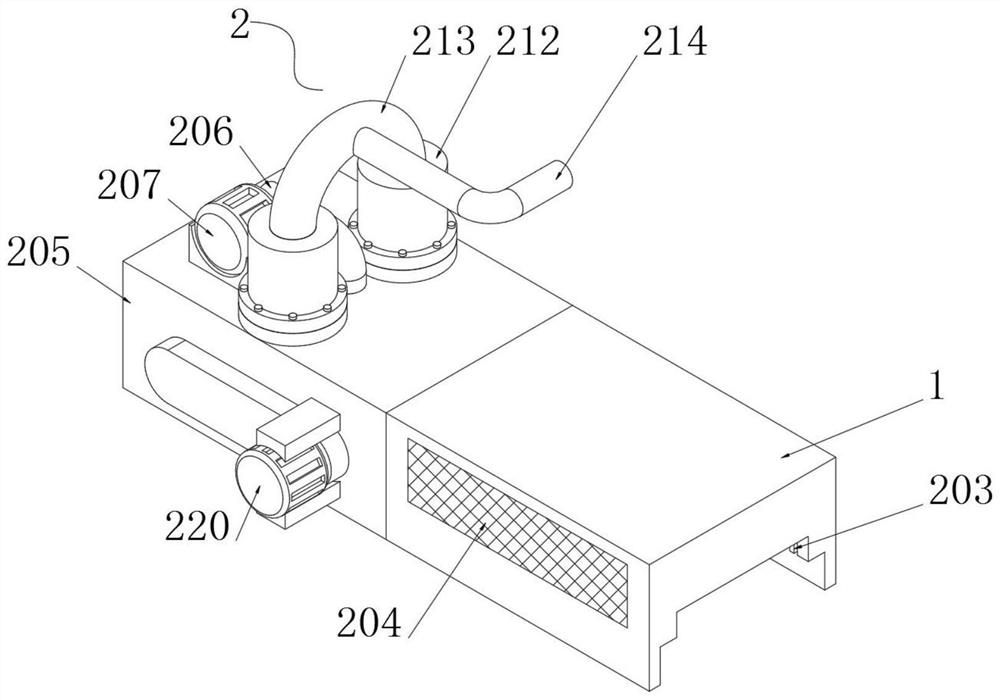

[0065] S4: Cooling down: through the cooling unit 2, air cooling and water cooling are performed on the cut steel;

[0066] S5: Heat energy recovery: recover heat energy through the recovery component 3 to reduce waste of resources;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com