An efficient directional radiation shielding protective structure and its 3D printing method

A 3D printing, directional radiation technology, applied in shielding, 3D object support structures, reactors, etc., can solve the problems of difficult processing, many processing defects of matrix materials and reinforcement materials, and suboptimal performance, and achieve controllable mechanical properties. , the effect of controllable shielding performance and lightweight cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

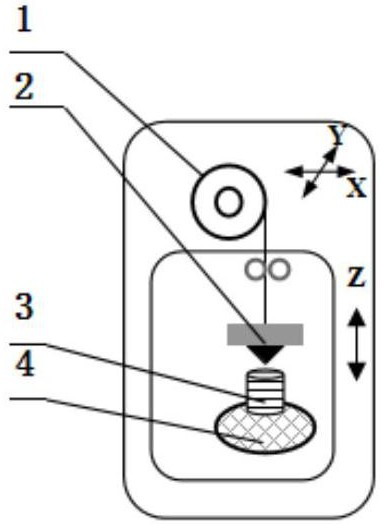

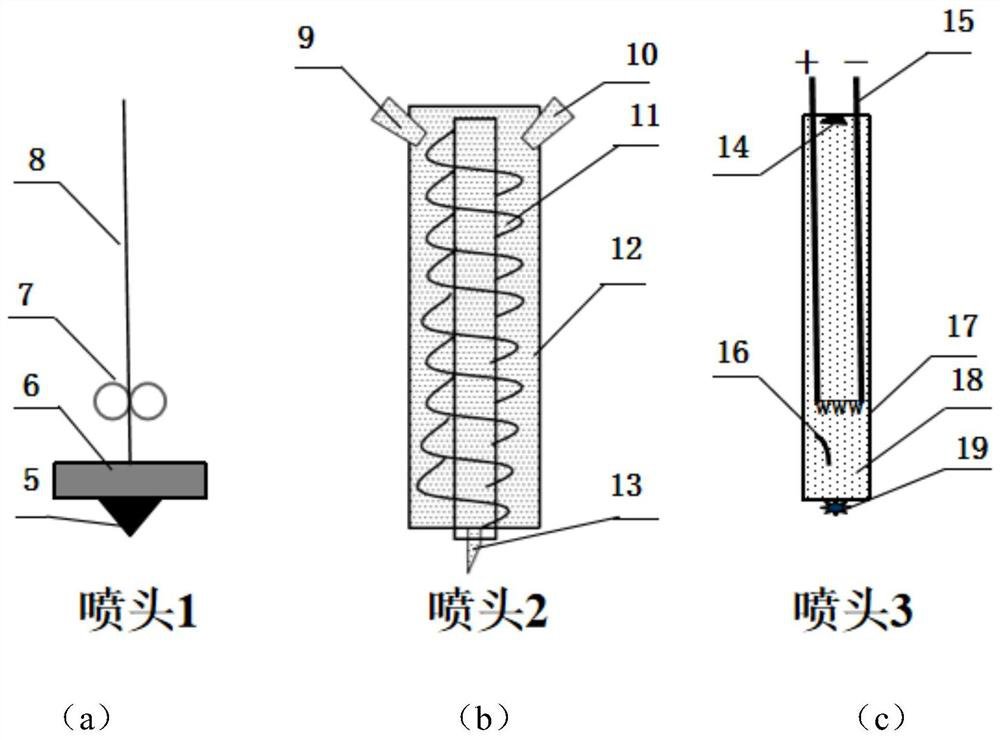

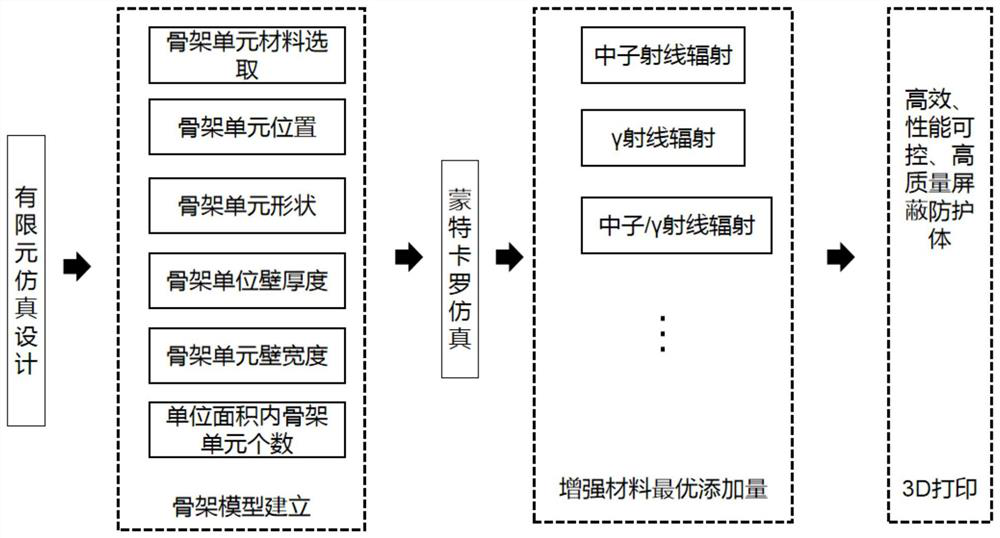

Method used

Image

Examples

Embodiment

[0069] Objective: To shield neutron gamma rays in an environment of 300°C, and make a cuboid solid-filled shield with a size of 300cm (length) × 300cm (width) × 100cm (height) as an example.

[0070] Frame material selection: choose PEEK, a high-temperature material with a melting point of 343°C, or a more high-temperature-resistant material;

[0071] Skeleton unit selection: PEEK material can be selected as the skeleton unit, 10% PEEK carbon fiber material, 30% wtPEEK boron carbide composite material, 85% wtPEEK tungsten composite material can also be selected. Among them, 10% PEEK carbon fiber material is the best, with the smallest thermal expansion coefficient. At the same time, PEEK carbon fiber composite material has excellent mechanical properties.

[0072] Shield production: take 10% PEEK carbon fiber as an example to make the outer contour and skeleton. The shape of the skeleton unit is hexagonal, circular, and cross-shaped. The shape, size, and depth of the skeleton...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com