Primary frequency modulation composite control system for coal-fired unit and working method of system

A composite control and coal-fired unit technology, applied in separation methods, chemical instruments and methods, mechanical equipment, etc., can solve problems such as slow load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

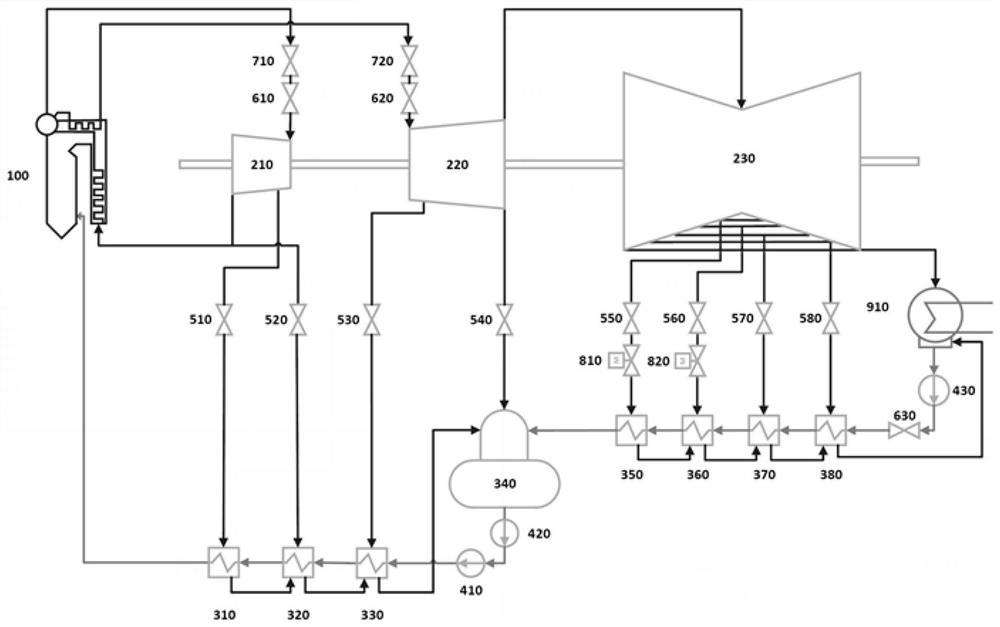

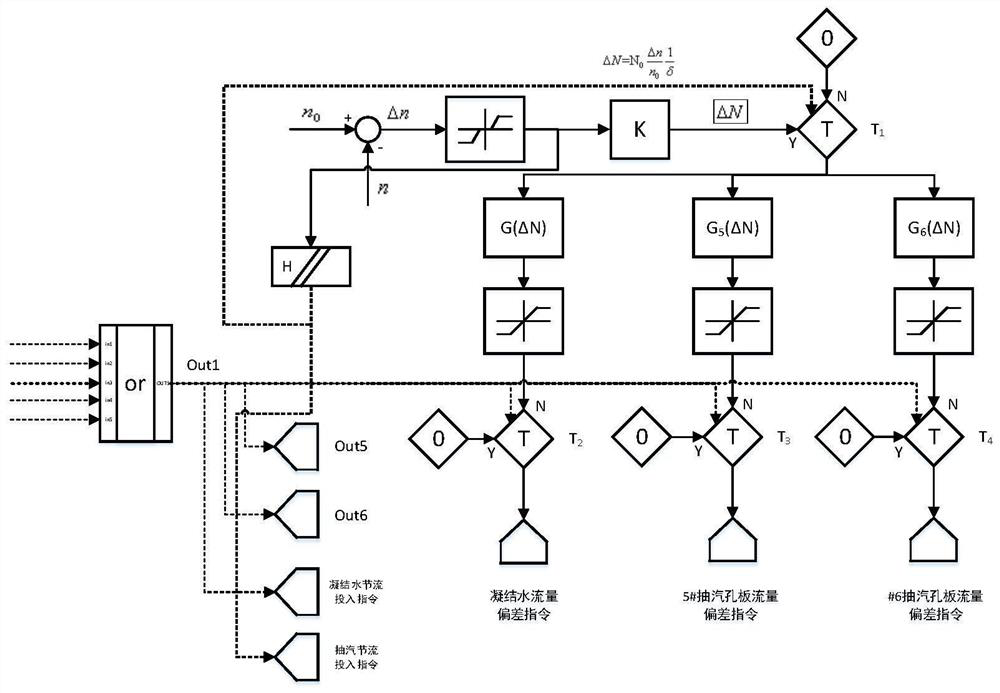

[0076] When the frequency of the power grid fluctuates, the frequency difference value triggers a high-value alarm, and the throttling system is put into operation. According to the frequency difference of the unit, the condensate flow deviation, the low-pressure heater 350 extraction steam flow deviation and the low-pressure heater 360 extraction steam flow deviation are calculated respectively. value. The condensate flow deviation value is sent to the control logic of the condensate regulating valve of the CDS condensate water system for further calculation; degree command; the deviation of the extraction steam flow of the low-pressure heater 360 is calculated through the flow characteristic curve of the throttle orifice 820 to obtain the opening degree command of the throttle orifice 820; The flow characteristic curve is calculated to obtain the opening instruction of the throttle orifice 830 .

example 2

[0078] When the power grid frequency is stable, the frequency difference value is lower than the insensitive area of the frequency modulation dead zone, the high value alarm value becomes False, the output flow deviation value of the condensate throttling system and the extraction steam throttling system are both 0, and the water level of the deaerator The control and heater extraction control are restored to stability, and the throttle orifice returns to the fully open state without any throttling effect.

example 3

[0080] In the process of putting into operation the primary frequency modulation system integrated control of condensate throttling and low plus extraction throttling, if the cut-off signal of the protection system is triggered, the flow deviation values output by the condensate throttling system and the extraction steam throttling system are equal. is 0, the primary frequency modulation system exits the frequency modulation process, and the throttle orifice returns to the fully open state without any throttling effect.

[0081] Image 6 and Figure 7 Comparing the load response curves of the existing condensate water throttling technology and the composite control system disclosed in the present invention, the response load target value of the unit is set to 27MW. Depend on Image 6 It can be seen that the unit adopts the existing condensate water throttling technology, and the actual value of the load response at 60 seconds is 24.8MW, and the response speed is relatively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com