Compound eye structure prepared based on femtosecond laser and provided with super-smooth surface

A technology of femtosecond laser and micro-nano composite structure, applied in the field of compound eye structure, can solve the problems of self-repair, easy to be polluted by liquid, easy to be atomized on the surface, etc., to achieve rich usage scenarios, low cost, and reduced processing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

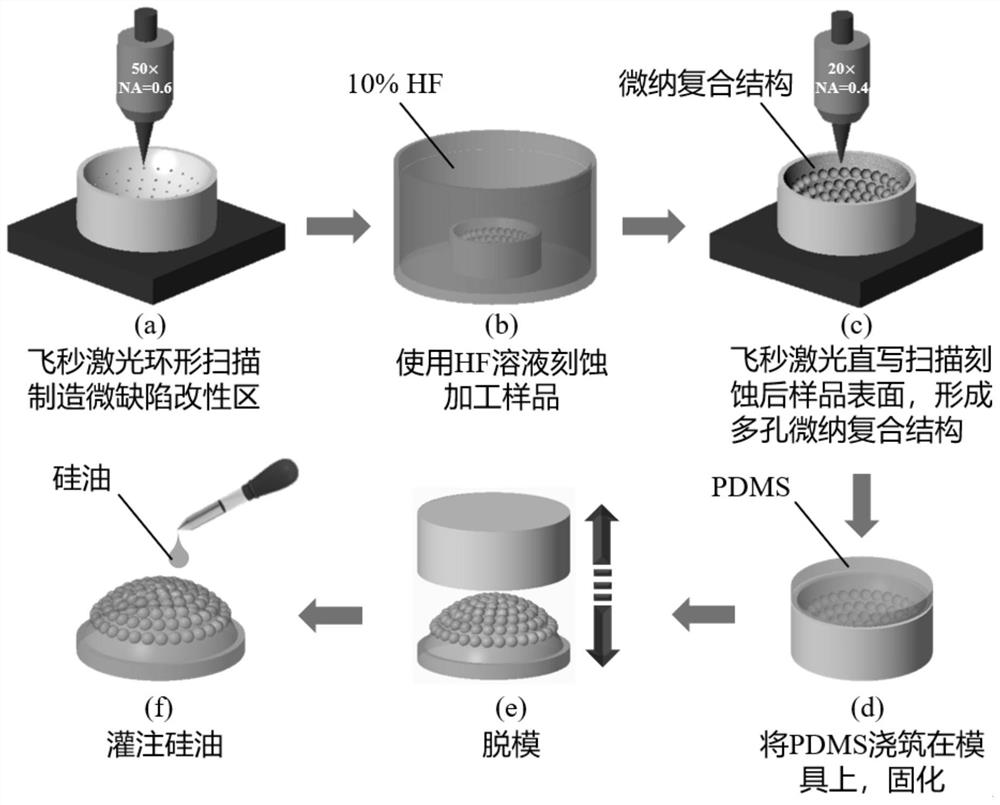

[0028] The realization of a compound eye structure with a supersmooth surface prepared by a femtosecond laser comprises the following steps:

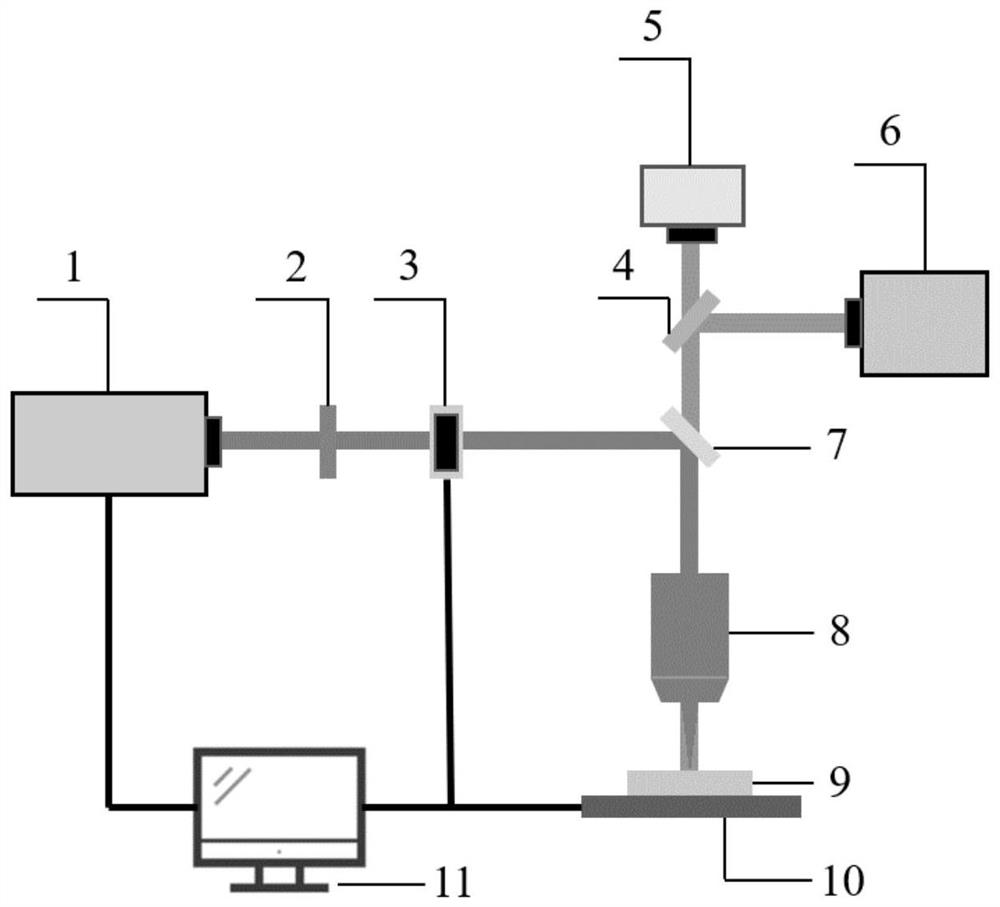

[0029] (1) As attached figure 1 As shown, the femtosecond laser system 1 generates a Gaussian laser with a wavelength of 800nm, a pulse width of 50fs, and a repetition frequency of 1kHz. The energy of the laser is changed through the attenuator 2, and the on-off of the mechanical switch 3 is controlled by the computer system 11, and the dichroic The mirror 7 changes the direction of the laser light, so that the laser light is vertically incident on the microscope objective lens 8 (50×, NA=0.6); the femtosecond laser beam focused by the objective lens is irradiated on the surface of the sample 9, which is fixed on the six-degree-of-freedom translation stage 10; During this process, the white light emitted by the white light source 5 passes through the beam splitter 4, the dichroic mirror 7, and the microscope objective lens 8 to irradiat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com