Upper reflecting layer structure, reactor core structure and high-temperature gas-cooled reactor

A core structure and reflective layer technology, applied in the core structure, upper reflective layer structure, and high-temperature gas-cooled reactor fields, can solve problems such as large flow resistance, no fluid distribution, and undesigned fluid distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

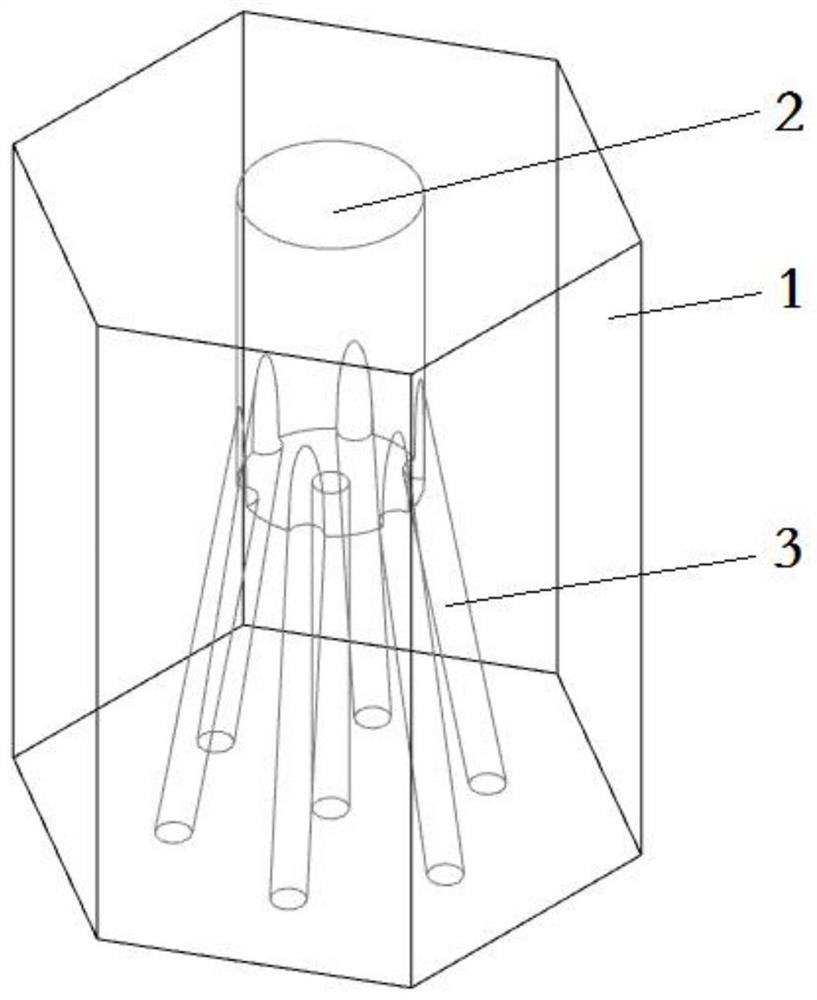

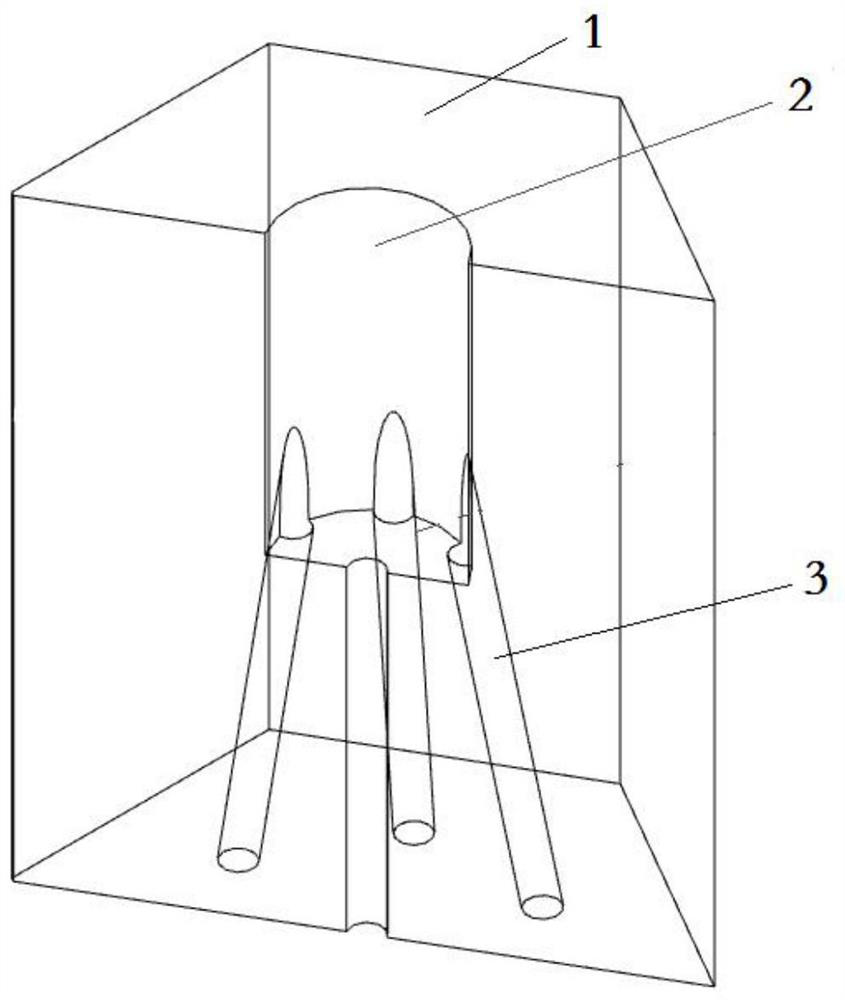

[0035] Such as figure 1 , figure 2 As shown, this embodiment discloses an upper reflective layer structure, which includes a plurality of graphite bricks 1 , and a chamber 2 and a plurality of channels 3 are arranged inside the graphite bricks 1 . The chamber 2 is arranged on the upper part of the graphite brick 1 for circulating coolant. A plurality of passages are arranged at the lower part of the graphite brick 1 , and the entrance of each passage 3 communicates with the chamber 2 , and the outlets of the passages are evenly distributed on the lower end surface of the graphite brick 1 .

[0036] Further, the diameters of the channels 3 on the graphite bricks are the same, so that the coolant can be evenly distributed after passing through the upper reflection layer, so as to ensure the uniformity of the coolant entering the fuel area. Certainly, the diameters of the plurality of channels 3 on each graphite brick in this embodiment may also be unequal, which may be specif...

Embodiment 2

[0043] This embodiment discloses a core structure, which includes a fuel region and an upper reflection layer arranged on the upper part of the fuel region. Multiple coolant channels are arranged in the fuel region, and the upper reflection layer adopts the above-mentioned upper reflection layer structure. The diameter of the chamber 2 and the aperture of the channel 3 on each graphite brick can be determined according to the coolant flow requirement of the corresponding fuel zone.

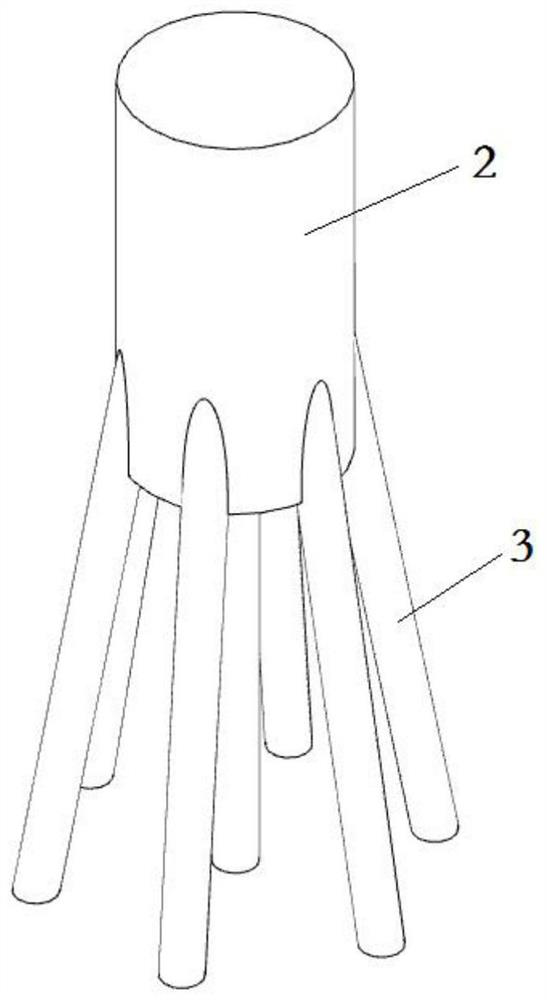

[0044] Further, each channel 3 on each graphite brick is docked or corresponds to each coolant channel on its corresponding fuel zone, for example, there can be 7 (such as image 3 shown), can also be 19 (such as Figure 4 shown) to ensure that coolant can enter the coolant passages that enter the fuel zone through the upper reflector.

[0045] Further, the diameter of each channel 3 of each graphite brick is equal to the diameter of the coolant channel on the corresponding fuel zone to ensure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com