Film with uniform water absorption, and preparation method thereof

A water-absorbing and uniform technology, used in non-aqueous electrolyte batteries, secondary battery repair/maintenance, electrical components, etc., can solve the problems of electrical performance impact, inability to feedback control the previous process, not mentioned, etc., to achieve high-performance diaphragms Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

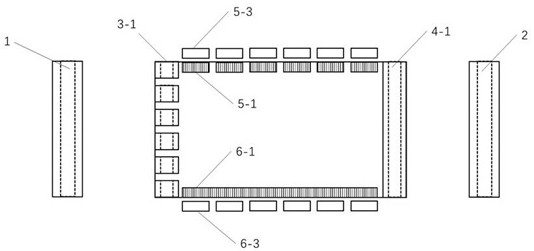

[0040]Hereinafter, exemplary embodiments of the present disclosure will be described in more detail with reference to the accompanying drawings. Although exemplary embodiments of the present disclosure are shown in the drawings, it should be understood that the present disclosure can be implemented in various forms and should not be limited by the embodiments set forth herein. On the contrary, these embodiments are provided to enable a more thorough understanding of the present disclosure and to fully convey the scope of the present disclosure to those skilled in the art.

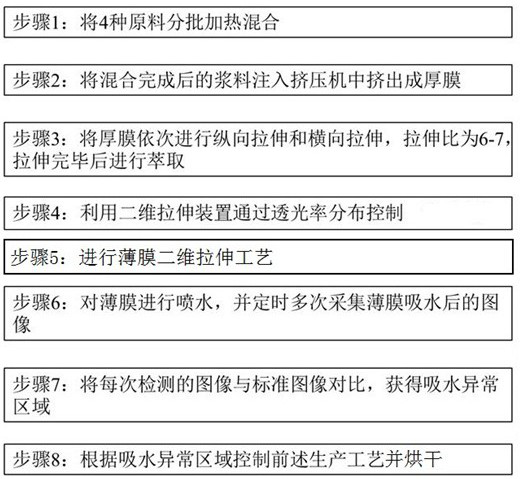

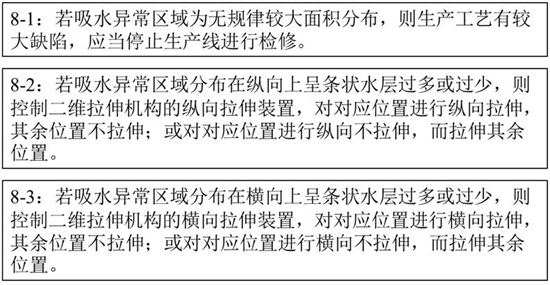

[0041]Diaphragm preparation method

[0042]The raw material A is polyethylene. Specifically, it may include the following two parts, and according to a large number of experiments, the preferred weight ratio between the two is 1:1.53.

[0043]A1: The molecular weight is 6.5×106-8.5×106Of polyethylene particles;

[0044]A2: The density is 0.966-0.983g / cm3Of polyethylene particles;

[0045]Raw material B is paraffin oil; raw mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com