Nitrogen-filled fresh-keeping packaging method and production process for high-efficiency and environmentally friendly tea or herbal tea

A packaging method and production process technology, which is applied in the field of high-efficiency and environmentally friendly tea or herbal tea nitrogen-filled and fresh-keeping packaging method and its production process, can solve the problems of tea quality, taste maintenance, low degree of industrialization, and high production cost, and achieves The effect of promoting the development process of industrialization, high degree of automation and saving packaging materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The present embodiment is a green tea packaging production line, comprising the following steps:

[0047] (1) Feeding: Put the green tea into the hopper of the Z elevator, and lift the green tea to the top of the 14-head combination scale through the lifting action of the Z elevator for feeding;

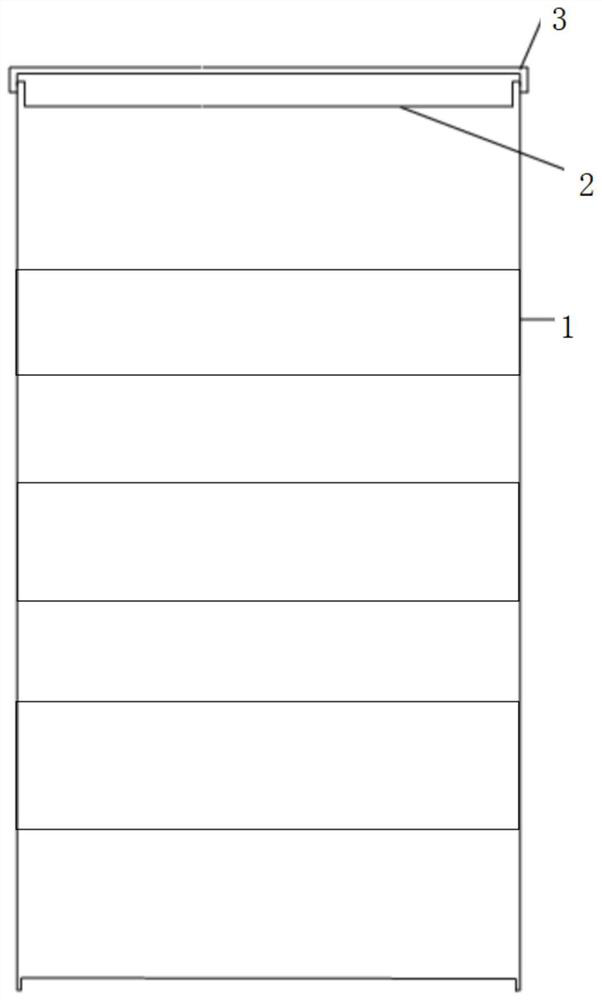

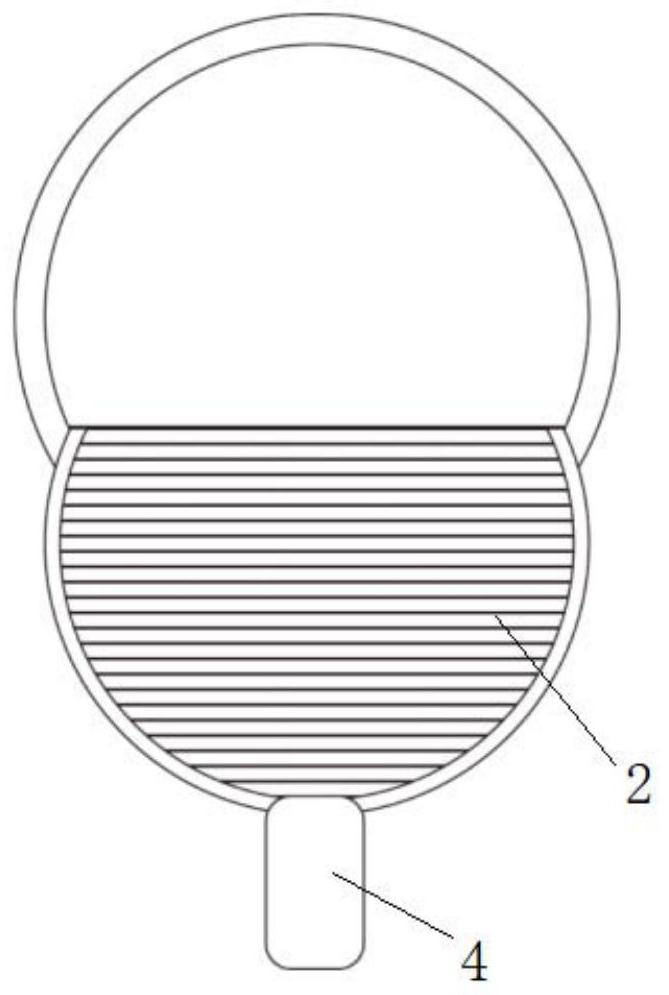

[0048] (2) Fully automatic weighing: the green tea put into the 14-head combination scale is transported to the weighing hopper for quantitative packaging of 14 parts, and then falls in sequence, and falls into the tinplate tank that is transported from the bottle unscrambler to the material receiving machine through the conveyor belt;

[0049] The weighing bucket is a special weighing bucket for green tea, which is suitable for weighing and quantifying various green teas.

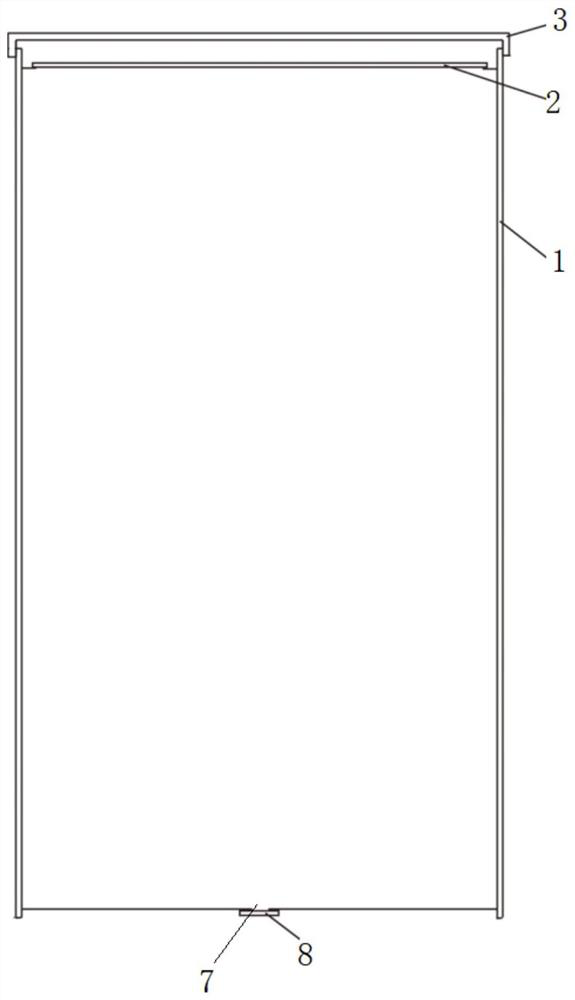

[0050] (3) Nitrogen-filling and sealing: tinplate cans filled with green tea are sent to the nitrogen-filling and sealing machine sequentially by the conveyor belt, and then sent out of the nitrogen-fillin...

Embodiment 2

[0060] The present embodiment is a black tea packaging production line, comprising the following steps:

[0061] (1) Feeding: Put the black tea into the hopper of the Z elevator, and lift the black tea to the top of the 14-head combination scale through the lifting action of the Z elevator for feeding;

[0062] (2) Fully automatic weighing: the black tea put into the 14-head combination scale is transported to the weighing hopper for quantitative packaging of 14 parts, and then falls in sequence, and falls into the tinplate tank that is transported to the material receiving machine by the bottle unscrambler through the conveyor belt;

[0063] The weighing bucket is a special weighing bucket for black tea, which is suitable for weighing and quantifying various black teas.

[0064] (3) Nitrogen-filling and sealing: tinplate cans filled with black tea are sent to the nitrogen-filling and sealing machine sequentially by the conveyor belt, and then sent out of the nitrogen-filling ...

Embodiment 3

[0073] This embodiment is a herbal tea packaging production line, including the following steps:

[0074] (1) Feeding: Put the herbal tea raw materials into the hopper of the Z elevator, and lift the black tea to the top of the 14-head combination scale through the lifting action of the Z elevator for feeding;

[0075] (2) Fully automatic weighing: the herbal tea raw materials put into the 14-head combination scale are transported to the weighing hopper for quantitative packaging of 14 parts, and then fall in sequence, and fall into the tinplate cans that are transported to the material receiving machine by the bottle unscrambler through the conveyor belt middle;

[0076] The weighing bucket is a special weighing bucket for herbal tea raw materials, which is suitable for weighing and quantifying various herbal teas.

[0077] (3) Nitrogen-filling and sealing: tinplate cans filled with herbal tea are sent to the nitrogen-filling and sealing machine in turn by the conveyor belt,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com