Plastering gypsum slurry and dry powder thereof

A technology for plastering gypsum and slurry, applied in the field of plastering gypsum slurry and its dry powder, can solve problems such as easy growth of mold, achieve a good comprehensive balance of mechanical properties and mildew resistance, improve construction performance, and reduce comprehensive production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

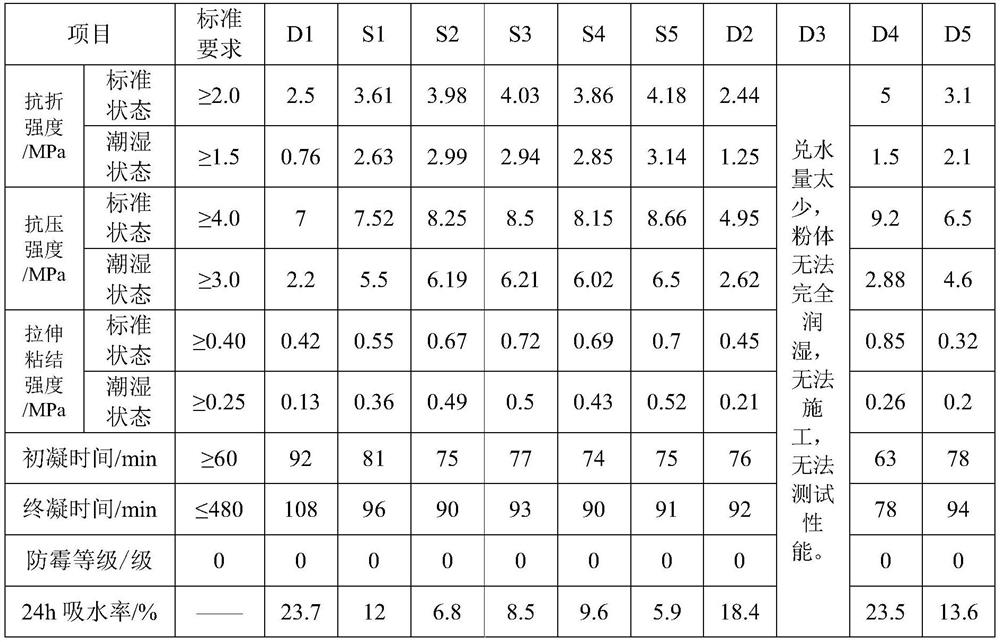

Examples

Embodiment 1

[0054]Hemihydrate gypsum 635Kg, vitrified beads 100Kg, heavy calcium 115.61Kg, zeolite 40Kg, silica fume 50Kg, calcium hydroxide 50Kg, polymer 3kg, water reducing agent 2Kg, water retaining agent 2Kg, retarder 0.39Kg, touch Change agent 1Kg, inorganic antifungal agent 1Kg, mix evenly, mix with water at 1:0.3 and stir evenly to obtain product S1.

Embodiment 2

[0056]Hemihydrate gypsum 635Kg, vitrified microbead 100Kg, heavy calcium 95.58Kg, zeolite 40Kg, silica fume 60Kg, calcium hydroxide 60Kg, polymer 3kg, water reducing agent 2Kg, water retaining agent 2Kg, retarder 0.42Kg, touch Change agent 1Kg, inorganic antifungal agent 1Kg, mix evenly, mix with water at 1:0.3 and stir evenly to obtain product S2.

Embodiment 3

[0058]Hemihydrate gypsum 685Kg, vitrified beads 100Kg, heavy calcium 42.55Kg, zeolite 40Kg, silica fume 60Kg, calcium hydroxide 60Kg, high molecular polymer 3kg, water reducing agent 2Kg, water retaining agent 2Kg, retarder 0.45Kg, touch Change agent 1Kg, inorganic antifungal agent 2Kg, mix evenly, mix with water at 1:0.3 and stir evenly to obtain product S3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com