Intelligent dedusting environment-friendly equipment and working method thereof

An environmental protection equipment and filter box technology, applied in chemical instruments and methods, mixing methods, separation methods, etc., can solve the problems of shortening the service life of the filter element, large dust, inconvenient centralized collection, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

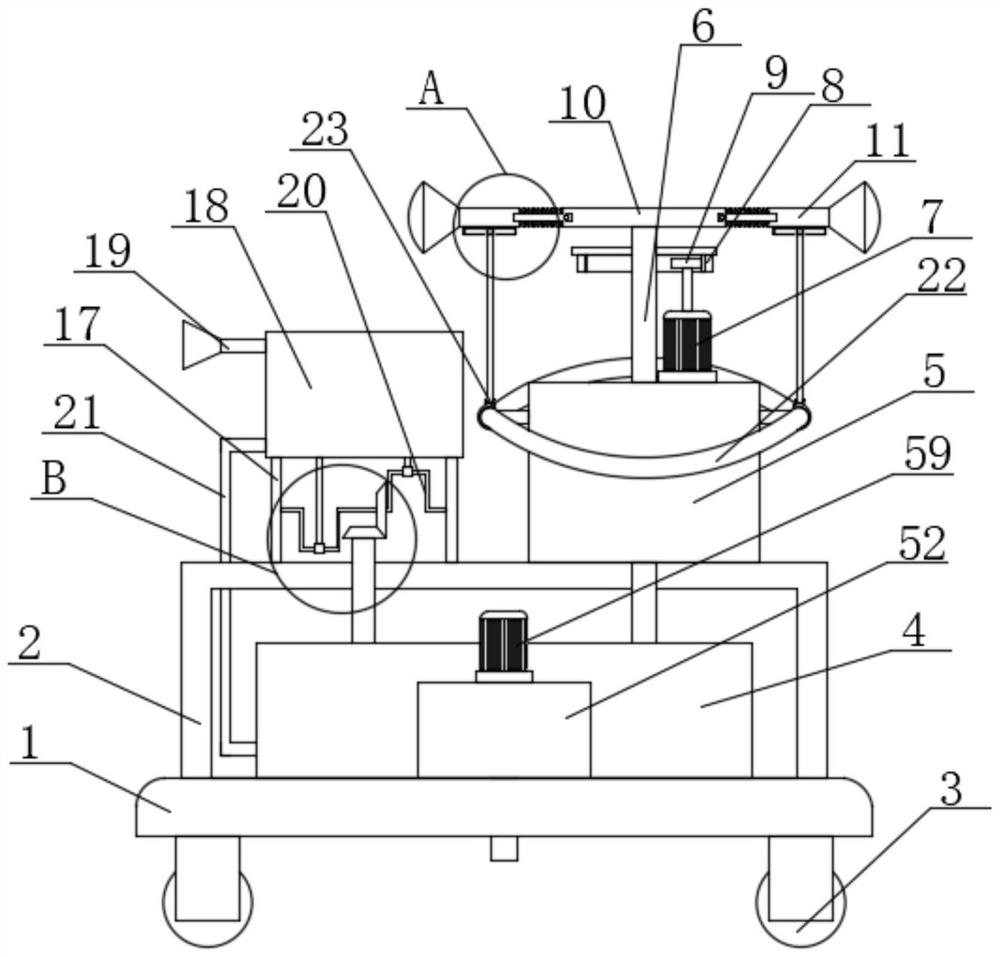

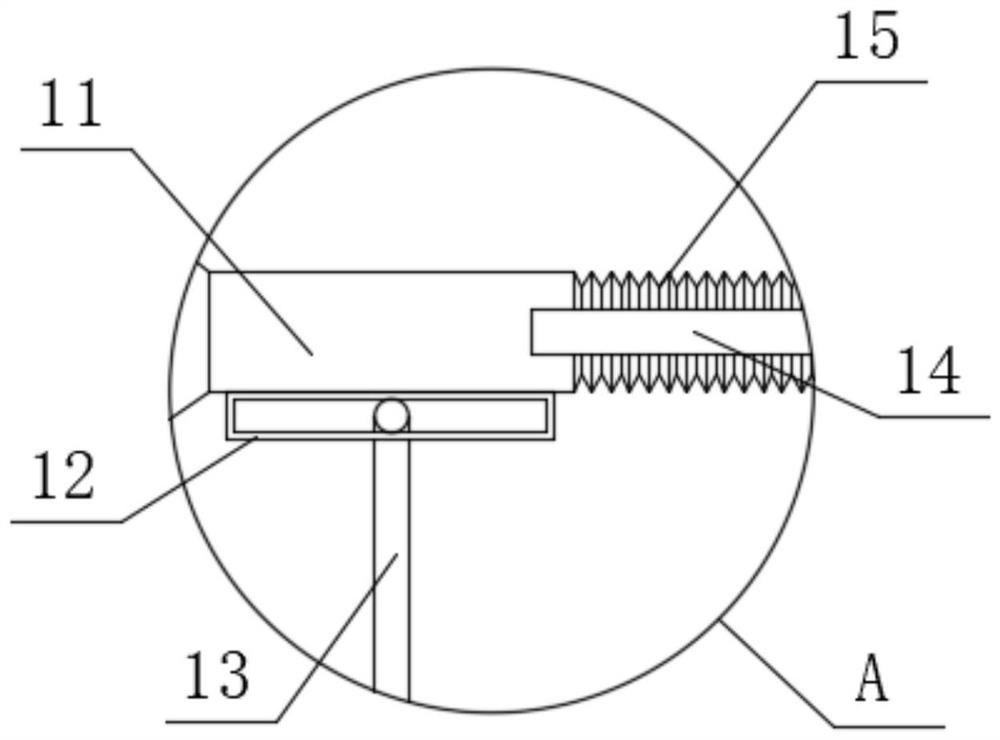

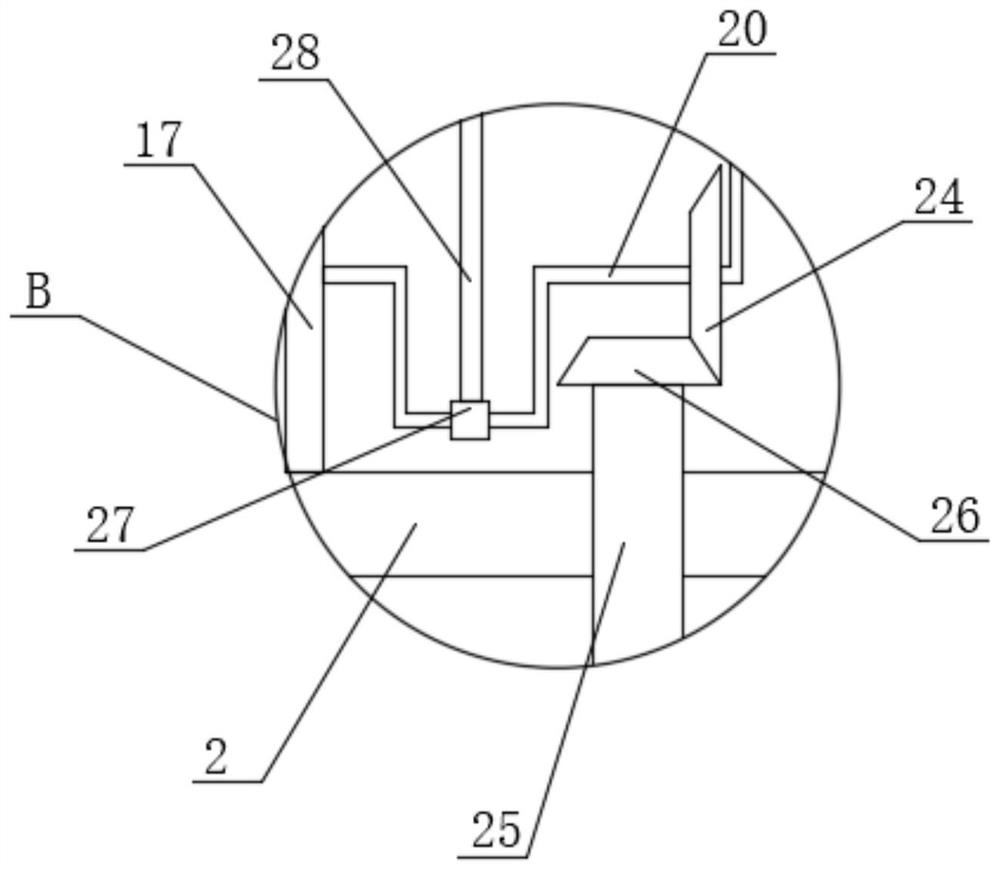

[0046] Embodiment one: if Figure 1-12 As shown, an intelligent dust removal and environmental protection equipment includes a base 1, wheels 3 are arranged on the four corners of the bottom of the base 1, and a mounting frame 2 and a first filter box 4 are respectively fixedly installed on the top of the base 1. The first filter box 4 is provided with water, and the first filter box 4 is located in the installation frame 2, the top side of the installation frame 2 is fixedly installed with the second filter box 5, and the top inner wall of the second filter box 5 is sealed and rotatably connected with a support pipe 6. The top of the support pipe 6 extends to the top of the second filter box 5 and is fixedly connected with the installation pipe 10, and the installation pipe 10 is connected with two nozzle pipes 11 for symmetrical rotation, and the installation pipe 10 is respectively connected with the two nozzle pipes 11 Through, the second filter box 5 is provided with a tr...

Embodiment 2

[0061] Embodiment two: if Figure 13-15 As shown, an intelligent dust removal and environmental protection equipment, the difference between this embodiment and the first embodiment is that the filter press assembly includes an electric push rod 59 fixedly installed on the top of the fixed box 52, and the bottom end of the electric push rod 59 extends to the press A pressure plate 61 is fixedly installed in the filter box 56, and a filter screen 62 below the pressure plate 61 is fixedly installed on the inner wall of the filter press box 56, and the output shaft of the electric push rod 59 is fixedly connected with the top of the pressure plate 61, and the filter press box 56 A drainpipe 57 is fixedly installed on the bottom inner wall of the first filter box 4, and the bottom end of the drainpipe 57 runs through the base 1 and extends to the bottom of the base 1. A water supply pipe 60 is fixedly installed on the bottom inner wall of the first filter box 4, and the water suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com