Tailing recycling device for starch glue production

A technology for starch glue and tailings, which is applied to mixers with rotary stirring devices, transportation, packaging, and dissolving directions, can solve the problems of no temperature control, uniform mixing and quantitative feeding, and achieve uniform mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

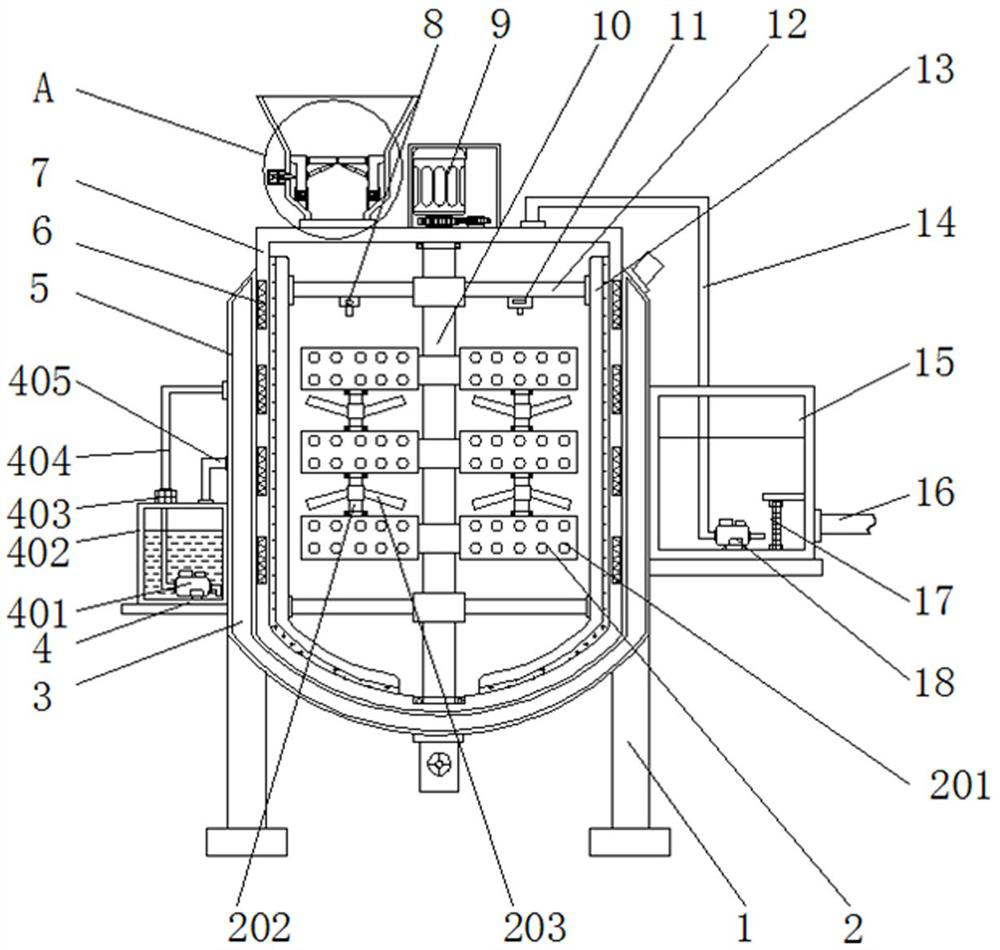

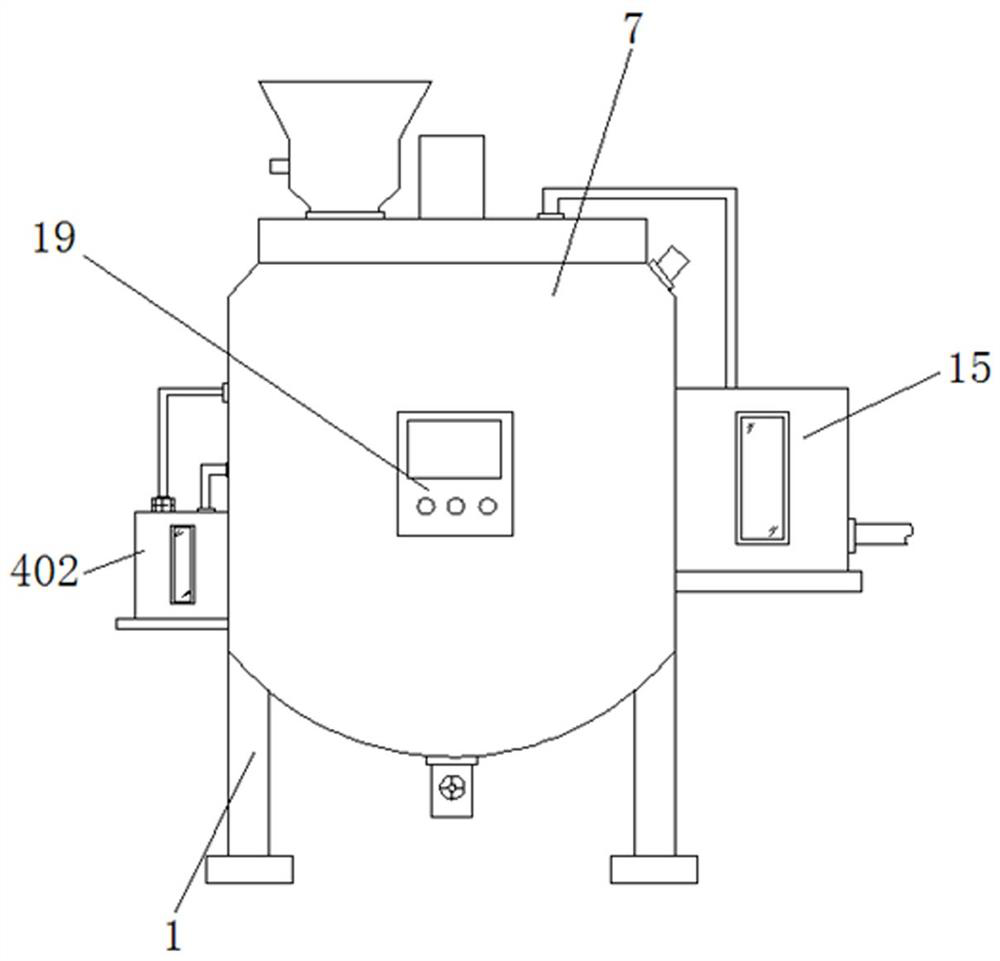

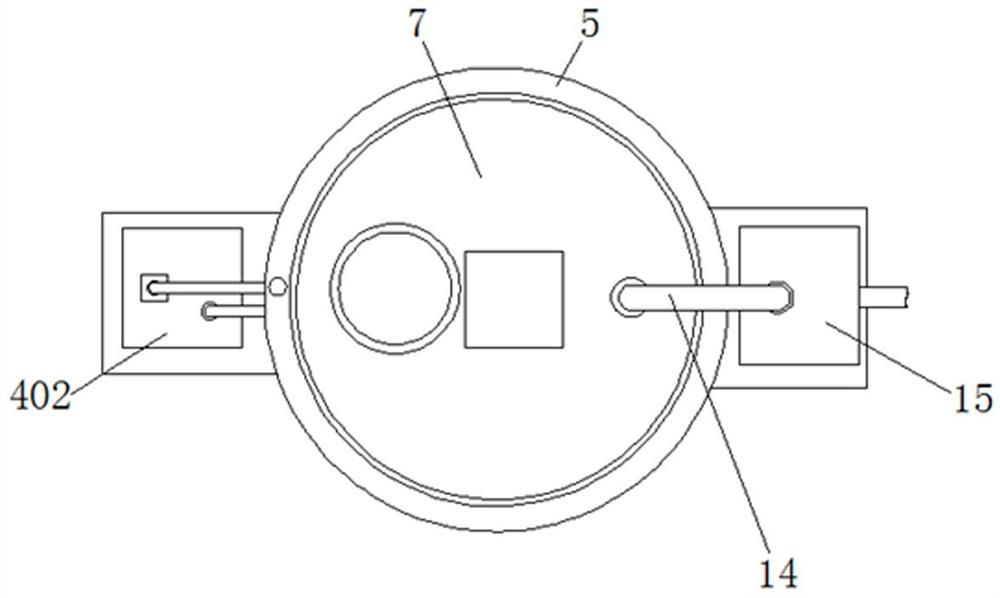

[0030] Example 1: See Figure 1-5 , a tailing recycling device for the production of starch glue, including a support leg 1, a scraper 13 and a baffle 26, and also includes a stirring mechanism 2 for conveniently mixing the starch glue evenly, and a cooling mechanism for temperature control 4 and the quantitative structure of quantitative feeding;

[0031] The top of the supporting leg 1 is equipped with a device body 7, and the outer wall of the device body 7 is equipped with a casing 5, the inside of the casing 5 is provided with a cold water chamber 3, the inside of the device body 7 is uniformly equipped with a heating wire 6, and the cooling mechanism 4 is installed on the One side outer wall of the shell 5;

[0032] The other side outer wall of shell 5 is equipped with recovery box 15, and the inwall of recovery box 15 is equipped with filter screen 17, and one side outer wall of recovery box 15 is connected with liquid inlet pipe 16, and the bottom end of recovery box ...

Embodiment 2

[0037] Embodiment 2: the cooling mechanism 4 includes a first water pump 401, a water tank 402, a refrigerator 403, a first output pipe 404 and a circulation pipe 405, the water tank 402 is installed on one side of the outer wall of the shell 5, and the bottom end of the water tank 402 is installed with a first A water pump 401, the model of the first water pump 401 can be 65ZW65-25, a refrigerator 403 is installed on the top of the water tank 402, the model of the refrigerator 403 can be DTA-40, and the top of the refrigerator 403 passes through the first output pipe 404 is connected to the outer wall of the shell 5, and one side of the top of the water tank 402 is connected to the outer wall of the shell 5 through the circulation pipe 405;

[0038] Specifically, such asfigure 1 , figure 2 with image 3 As shown, when using this structure, the mixture in the device body 7 is heated by the heating wire 6, and then the cold water in the water tank 402 is pumped by the first w...

Embodiment 3

[0039] Embodiment 3: Stirring mechanism 2 comprises the first stirring blade 201, stirring shaft 202, the second stirring blade 203, the first stirring blade 201 is installed on the outer wall of rotating shaft 10, all through bearing is installed between the outer wall of one end of stirring mechanism 2 shaft 202, and the outer wall of the stirring shaft 202 is equipped with a second stirring blade 203;

[0040] A rotary gear 20 is installed on the outer wall below the driving motor 9 , and a reduction gear 21 is installed on one side of the rotary gear 20 .

[0041] Both ends of the outer wall of the rotating shaft 10 are equipped with a connecting rod 12, and one end of the connecting rod 12 is equipped with a scraper 13, and one side of the bottom end of the connecting rod 12 is installed with a viscosity sensor 11, and the type of the viscosity sensor 11 can be SX166-FWS -3A, a temperature sensor 8 is installed on the other side of the top of the connecting rod 12, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com