Ultraviolet laser optical fiber ozone generator

An ozone generator and ultraviolet laser technology, applied in the field of chemical equipment generators, can solve the problems of insufficient ultraviolet light intensity, limited reaction contact surface, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

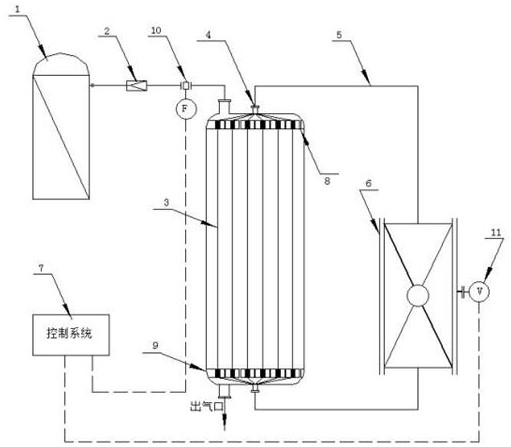

[0023] The present invention is further described below in conjunction with accompanying drawing.

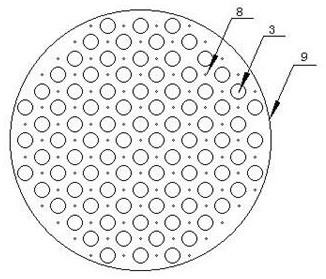

[0024] like figure 1 Shown, a kind of ultraviolet laser optical fiber ozone generator comprises oxygen tank 1, is characterized in that, is provided with decompression valve 2 and flow transmitter 10 on the communicating pipeline between oxygen tank 1 and ozone generator 3; 3 The fiber coupler 4 at the upper end is connected to the ultraviolet laser light source 6 through the conductive optical fiber 5, and the lower end is connected to the dispersion optical fiber in the ozone generator; one end of the ultraviolet laser light source 6 is connected to the control system 7 through the voltage regulator 11; the flow transmitter 10 is connected to the control system 7. An optical fiber fixing plate 9 is provided on the upper and lower sides of the ozone generator 3, the optical fiber fixing plate 9 is provided with a gas channel 8, and the bottom of the ozone generator 3 is provide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com