Zeolite carrier concrete internal curing agent as well as preparation method and application thereof

A concrete curing agent technology, applied in the field of concrete, can solve the problems of difficult uniform dispersion and complicated material sources, and achieve the effects of low cost, early shrinkage inhibition, and easy popularization and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

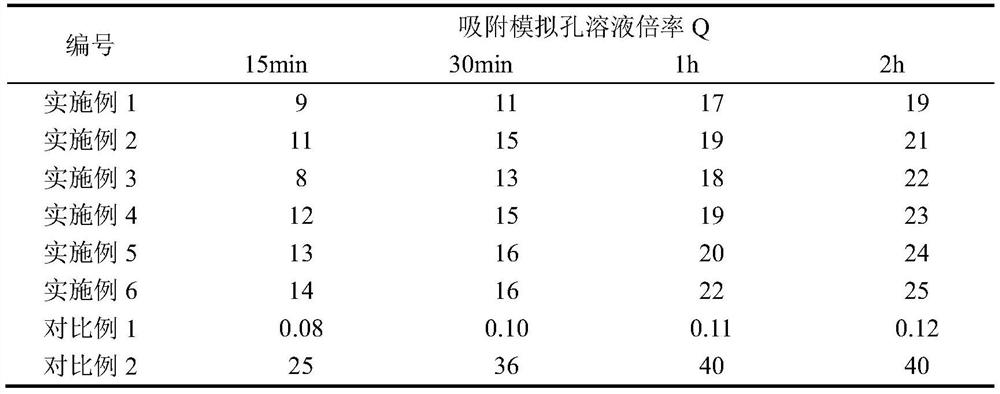

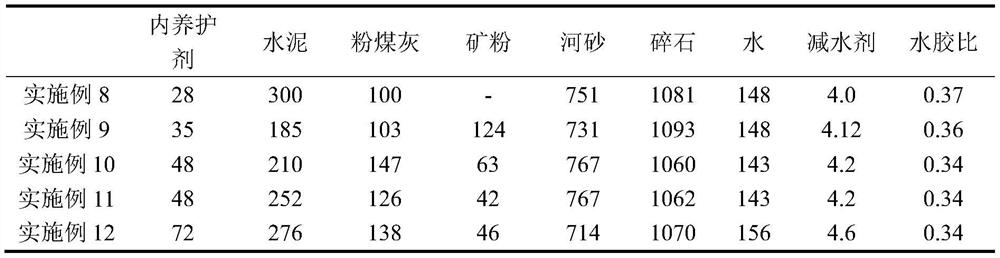

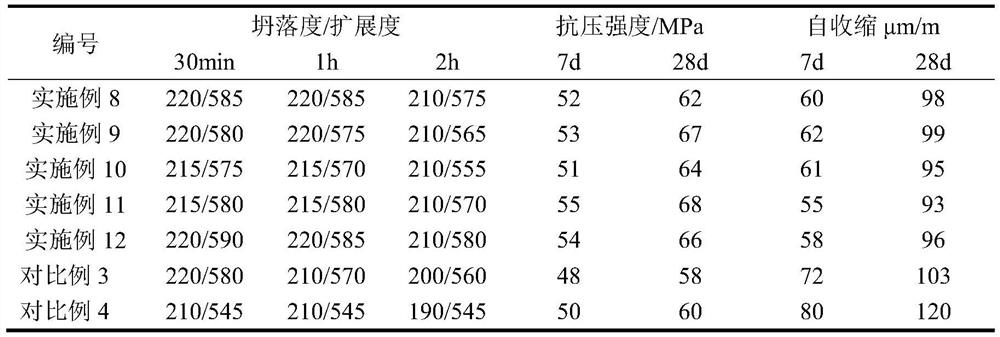

Examples

preparation example Construction

[0036] In addition, the present invention also discloses a preparation method of the above-mentioned internal curing agent, which includes the following steps:

[0037] 1) The parts by mass are deionized water: 100-300 parts, acrylic compound: 4.5-10 parts, acrylamide compound: 50-100 parts, sodium hydroxide: 20-50 parts, cross-linking agent: 0.05- 0.2 parts and initiator: 0.05 to 0.2 parts of each raw material component are mixed and reacted to prepare a water-absorbing polymer as a core-shell structure core solution; the water-absorbing capacity of the water-absorbing polymer in fresh water is not less than 40 times.

[0038] 2) Take the porous zeolite and soak it in the nuclear solution of step 1) until it is completely saturated, then take it out and drain it; generally soak for about 45 minutes. The mass of the porous zeolite is 0.5-2wt% of the mass of the nuclear solution; during this step, the water-absorbing polymer is adsorbed inside the porous zeolite, and the water-a...

Embodiment 1

[0046] This embodiment discloses a kind of preparation method of internal maintenance agent, it comprises the steps:

[0047] 1) The parts by mass are deionized water: 100 parts, acrylic acid: 4.5 parts, methacrylamide: 50 parts, sodium hydroxide: 20 parts, N,N'-methylenebisacrylamide: 0.05 parts and over Potassium sulfate: 0.05 parts of each raw material component is mixed and reacted to prepare a water-absorbing polymer as a core-shell structure core solution; 2) The average particle size is 0.02mm, and the specific surface area is >800m 2 / g, the natural zeolite with a porosity of 50% is immersed in the nuclei solution of step 1) and soaked until fully saturated for 45min and then taken out and drained; the quality of the natural zeolite is 0.5wt% of the nuclei solution quality; during this step , the water-absorbing polymer is adsorbed inside the porous zeolite, which better retains the water-absorbing and water-releasing properties of the water-absorbing polymer;

[0048...

Embodiment 2

[0050] This embodiment discloses a kind of preparation method of internal maintenance agent, it comprises the steps:

[0051] 1) The parts by mass are deionized water: 300 parts, methacrylic acid: 10 parts, N-methylolacrylamide: 100 parts, sodium hydroxide: 50 parts, ethylene glycol dimethacrylate: 0.2 parts And sodium persulfate: 0.2 parts of each raw material component mixed reaction to prepare water-absorbing high molecular polymer as core-shell structure core solution; 2 / g, the natural zeolite with a porosity of 60% is immersed in the nuclei solution of step 1) and soaked until fully saturated for 45min and then taken out and drained; the quality of the natural zeolite is 2wt% of the nuclei solution quality; during this step, The water-absorbing polymer is adsorbed inside the porous zeolite, which better retains the water-absorbing and water-releasing properties of the water-absorbing polymer;

[0052] 3) The product obtained in step 2) is placed in a microwave reactor, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com