Artificial stone whitened by composite pigment and preparation method of artificial stone

A composite pigment and artificial stone technology, applied in the field of artificial stone production, can solve the problems of high addition of titanium dioxide, easy discoloration of white artificial stone, etc., and achieve the effects of easy fading or discoloration, not easy to fade or discoloration, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] A method for preparing artificial stones whitened by composite pigments, for preparing the artificial stones whitened by composite pigments, comprising the following steps:

[0052] (1) Preparation of composite pigment: pre-disperse titanium dioxide in water to obtain titanium dioxide suspension, mix the pre-ground wollastonite powder with the titanium dioxide suspension evenly, and then place it in an ultrafine stirring mill The composite slurry is prepared by medium grinding, and the composite slurry is dehydrated, dried and dispersed to obtain a composite pigment;

[0053] (2) Mixing of raw materials: mix resin, aggregate, filler, curing agent and coupling agent and stir evenly to obtain a mixture;

[0054] (3) Fabric: feed the mixture into the fabric frame;

[0055] (4) Pressing: vacuumize and press the mixed material in the cloth frame to obtain the green body;

[0056] (5) Curing: demoulding after curing the green body;

[0057] (6) Post-treatment: post-process...

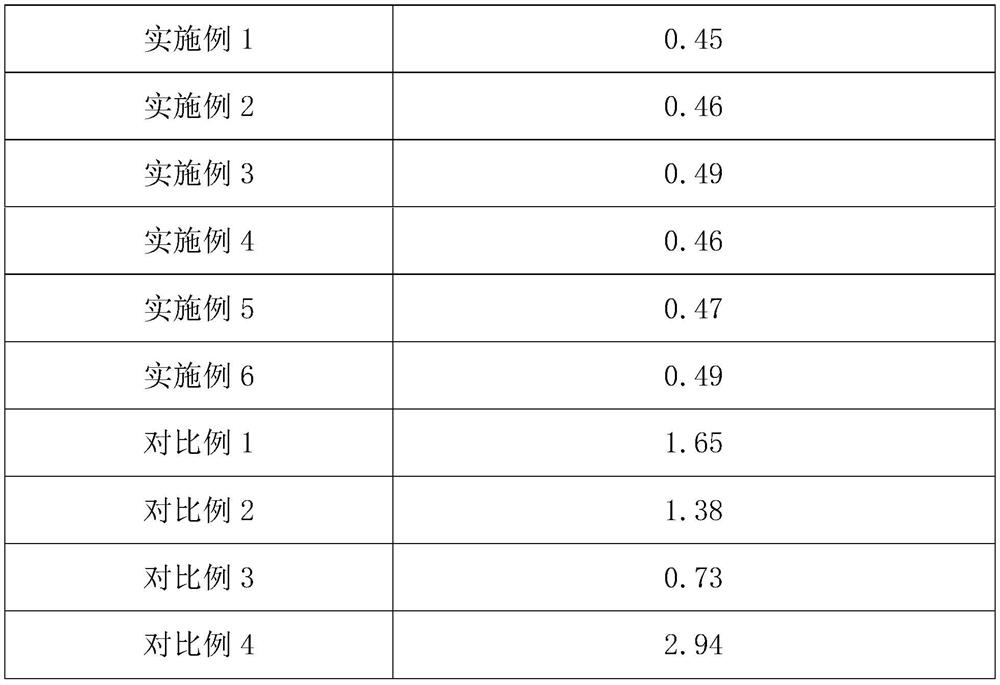

Embodiment 1~5

[0080] A kind of artificial stone that adopts composite pigment to whiten, prepare raw material according to the raw material formula of table 1 standby, and prepare according to the following steps:

[0081] (1) Preparation of composite pigment: pre-disperse titanium dioxide in water to obtain titanium dioxide suspension, mix the pre-ground wollastonite powder and titanium dioxide suspension evenly, and then grind in an ultrafine stirring mill The composite slurry is obtained, and the composite slurry is dehydrated, dried and dispersed to obtain a composite pigment;

[0082] (2) Mixing of raw materials: first add coupling agent to the resin, then add composite pigment and / or colored pigment to mix and disperse with colloid mill to obtain suspension, then add the suspension to pre-mixed uniform aggregate, In the filler and the curing agent, mix and stir evenly to obtain the mixture;

[0083] (3) Fabric: feed the mixture into the fabric frame;

[0084] (4) Pressing: vacuumize...

Embodiment 6

[0095] A kind of artificial stone that adopts composite pigment to whiten, prepare raw material according to the raw material formula of embodiment 5 in table 1 standby, and prepare according to the following steps:

[0096] (1) Preparation of composite pigment: pre-disperse titanium dioxide in water to obtain titanium dioxide suspension, mix the pre-ground wollastonite powder and titanium dioxide suspension evenly, and then grind in an ultrafine stirring mill The composite slurry is obtained, and the composite slurry is dehydrated, dried and dispersed to obtain a composite pigment;

[0097] (2) Mixing of raw materials: first mix the aggregate and the composite pigment evenly according to the ratio of 20:1, then add them to the pre-mixed filler, coupling agent, curing agent and the remaining aggregate, mix and stir evenly to obtain Mixture;

[0098] (3) Fabric: feed the mixture into the fabric frame;

[0099] (4) Pressing: vacuumize and press the mixed material in the cloth ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com