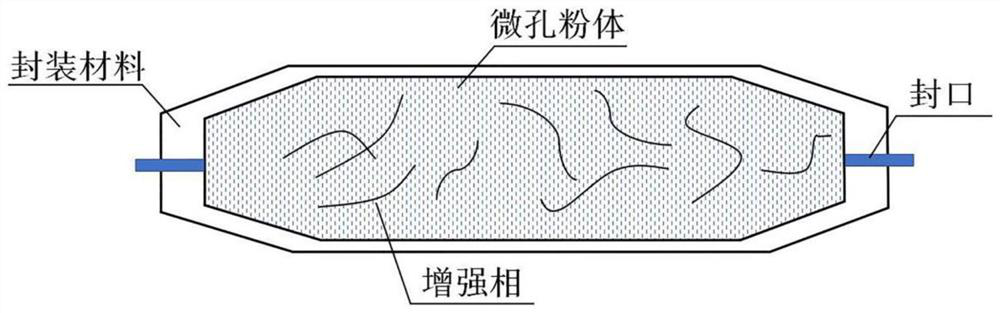

Preparation method of vacuum-packaged/ microporous powder composite high-temperature thermal insulation material

A technology of vacuum packaging and heat insulation materials, applied in the field of refractory materials, can solve the problems of low average thermal efficiency of kilns, reduction of material heat insulation capacity, energy waste, etc., to achieve the goal of ensuring vacuum degree, improving heat insulation capacity, and low raw material cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

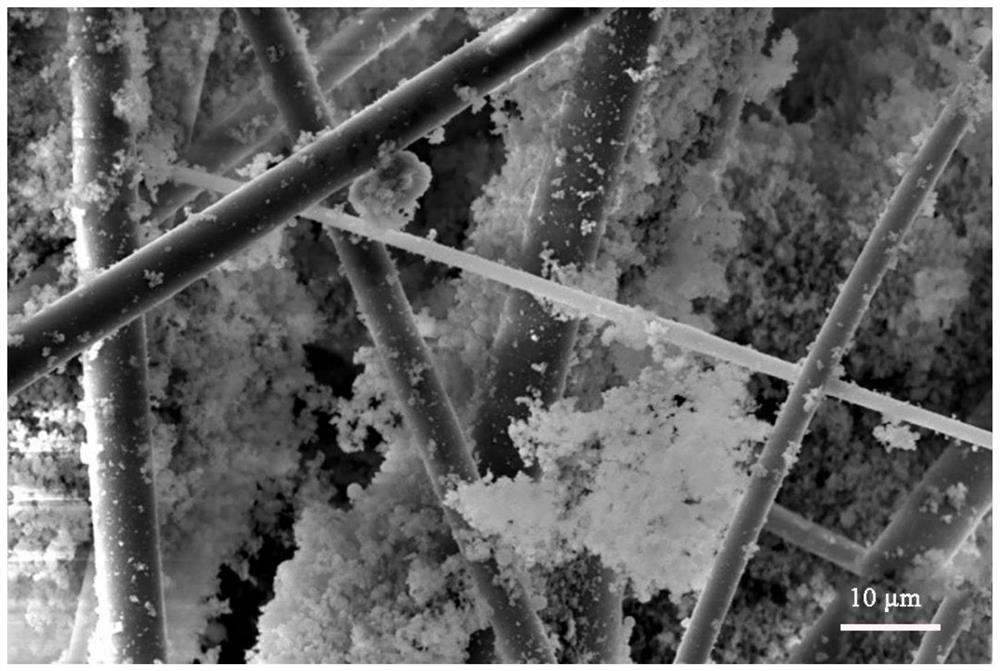

[0032] An embodiment of the preparation method of the vacuum packaging / microporous powder composite high-temperature heat-insulating material of the present invention, the preparation method of the high-temperature heat-insulation material described in this embodiment is:

[0033] (1) Weigh the raw materials according to the formula, all by mass percentage, the raw materials and their proportioning ratio are: SiO 2 -Al 2 o 3 Micronized powder is 90%, ZrO 2 Fiber is 5%, TiO 2 Micronized powder is 5%. Put the raw materials in a high-speed mixer, the stirring speed is 2000r / min, the stirring time is 5min, and mix well. Put the mixed raw materials into the mold, press and form under the pressure of 0.2MPa, and the thickness of the prepared microporous powder composite slab is 15mm;

[0034] (2) Put two SiO sheets of the same size and shape 2 The ceramic film is aligned, and the three sides are hot-pressed and sealed into a bag shape. After cooling, the microporous powder com...

Embodiment 2

[0039] An embodiment of the preparation method of the vacuum packaging / microporous powder composite high-temperature heat-insulating material of the present invention, the preparation method of the high-temperature heat-insulation material described in this embodiment is:

[0040](1) Weigh the raw materials according to the formula, all by mass percentage, the raw materials and their proportioning ratio are: SiO 2 -Al 2 o 3 Micronized powder is 85%, ZrO 2 Fiber is 6%, TiO 2 Micronized powder is 9%. Put the raw materials in a high-speed mixer, the stirring speed is 2000r / min, the stirring time is 5min, and mix well. Put the mixed raw materials into the mould, press and form under the pressure of 0.4MPa, and the thickness of the prepared microporous powder composite slab is 20mm;

[0041] (2) Put two SiO sheets of the same size and shape 2 The ceramic film is aligned, and the three sides are hot-pressed and sealed into a bag shape. After cooling, the microporous powder com...

Embodiment 3

[0046] An embodiment of the preparation method of the vacuum packaging / microporous powder composite high-temperature heat-insulating material of the present invention, the preparation method of the high-temperature heat-insulation material described in this embodiment is:

[0047] (1) Weigh the raw materials according to the formula, all by mass percentage, the raw materials and their proportioning ratio are: SiO 2 -Al 2 o 3 Micronized powder is 80%, ZrO 2 Fiber is 8%, TiO 2 Micronized powder is 12%. Put the raw materials in a high-speed mixer, the stirring speed is 2000r / min, the stirring time is 5min, and mix well. Put the mixed raw materials into the mold, press and form under the pressure of 1.2MPa, and the thickness of the prepared microporous powder composite slab is 25mm;

[0048] (2) Put two SiO sheets of the same size and shape 2 The ceramic film is aligned, and the three sides are hot-pressed and sealed into a bag shape. After cooling, the microporous powder co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com